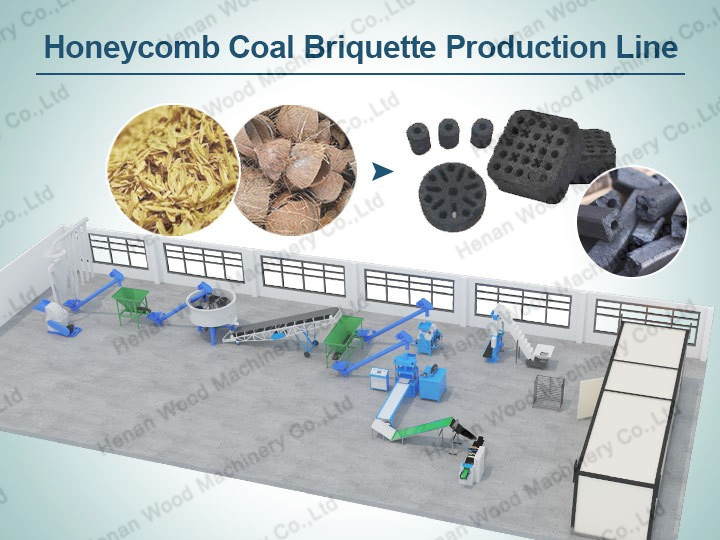

The honeycomb coal briquette production line is the equipment to produce porous charcoal, this production line includes the steps of carbonizing raw materials, crushing, mixing with binder, molding, and also drying, etc. The shape of honeycomb coal can be various, and the mold can be replaced. Honeycomb coal briquette is usually used in heating, barbecue, industrial production, pharmaceutical production, and other industries.

Honeycomb coal briquette production line raw materials

Honeycomb coal briquette production line can use a wide range of raw materials, usually, rice husk, logs, bamboo, peanuts can be, walnut shells, coconut shells, and all kinds of nut shells. Many raw materials can be used for processing honeycomb coal, and as long as there are enough raw materials, they can be used for carbonization, there are many kinds of carbonization furnaces in Shuliy, such as hoisting carbonization furnace, horizontal carbonization furnace, continuous carbonization furnace, which can be applied to various sizes of raw materials.

Multi-shaped charcoal of honeycomb coal production line

The honeycomb coal briquette production line can produce different kinds of honeycomb coal, one only needs to change the mold of the machine, so this production line can produce several different kinds of honeycomb coal. And it is very convenient to change the molds, you can buy many kinds of molds when you buy the machine, and you can change them by yourself. The machine can be processed into cylindrical, square, and hexagonal shapes. The holes of charcoal can also be customized, usually one hole, three holes, or multiple holes.

Honeycomb coal briquette production line composition

raw material carbonization

This process is an important step in the honeycomb coal briquette production line, the main purpose of which is to carbonize the organic material in the raw material into solid charcoal, removing moisture and volatile components, increasing the carbon content of the charcoal, and fixing the calorific value of the charcoal.

charcoal crushed

The main purpose of crushing the charred material is to make the raw material easier to shape and press, increasing the surface area of the raw material and facilitating the subsequent molding process of making honeycomb coal.

charcoal grinding

This step in the honeycomb coal briquette production line helps to ensure the uniformity and stability of the honeycomb coal, and the ground material is easier to mix with the binder to form a mixture suitable for pressing and molding.

wood charcoal powder and binder mix

This process involves mixing and stirring the charcoal powder and binder with water for about 5-10 minutes.

honeycomb forming process

The most critical equipment in the honeycomb coal briquette production line. Mixed coal dust, binder, and other raw materials are fed into the honeycomb machine, which undergoes a series of molding, compression, and curing steps to form a sturdy honeycomb coal structure.

Advantages of charoal briquette press machine

The composition of honeycomb coal is the same compared with other charcoal, which is all carbon powder, but because honeycomb coal is porous and dense, honeycomb coal burns longer, is more resistant to burning, and is clean and sanitary. The holes of charcoal can increase the area of charcoal when it burns so that the charcoal can burn fully and reduce the waste of resources.

Honeycomb coal briquette production line workflow

Generally, the raw material is first put into a carbonization furnace to carbonize, then crushed, mixed with a binder, and finally formed. The machines used are a carbonization furnace, hammer mill, Raymond mill, wheel mill, and molding machine, and our company also has carbon drying equipment. We have two different types of dryers, one is a cart-type dryer and the other is a continuous mesh belt dryer.

Introduction of honeycomb coal forming machine

The honeycomb coal forming machine is the core of the honeycomb coal briquette production line, it is mainly used to shape the carbon powder which is well mixed with binder, and produce unshaped charcoal by changing the mold. The main components of the honeycomb coal-forming machine are five parts: body, rotation, feeding, stamping, and conveying. With a high degree of automation, the production process kind can realize fully automatic production and save labor costs.

Parameters of coal briquette press machine

| Mold | XFM125 | XFM83 | FM220 | FMJ102 | FMJ-120 |

| Forming height (mm) | 70-100 | 70-90 | 75-90 | 70-80 | 70-80 |

| Stamping times (times/min) | 48 | 48 | 35 | 45 | 48 |

| Motor power (kw) | 7.5 | 7.5 | 11 | 4.5 | 7.5 |

| Machine weight (kg) | 1600 | 1800 | 3800 | 1100 | 1400 |

| Formed coal specification (mm) | φ100×75 φ125×75 | φ150×90 φ140×90 | φ220×90 φ200×90 | φ100×75 φ120×75 | φ120×75 φ100×75 |

Structure of honeycomb briquette forming machine

- Body part: composed of table plate, machine base, open into the skeleton entity of the machine.

- The transmission part: by the motor, pulley, gears, transmission shaft, and other components. Motor through the pulley to make the gear shaft rotation and through the two gears to the transmission shaft, and through a pair of bevel gears and the rotation shaft drive the dial, dial dial dial to the four-hole disk movement.

- Feeding part: It consists of a rotating shaft, hopper, and mixer. The axial gear pivots the mixer to stir the coal and load it into the mold cylinder.

- The stamping part mainly consists of four sliding rods, a sliding beam, a punching rod, a punching rod seat, a punch, a movable pressure plate, a movable die bottom, and a spring. When the machine is rotated by two gears, the slide beam is driven by the tie bar, and the punch goes down, forcing the punch to move down and the movable plate to move up with the spring tightened, pressing the coal into shape and punching the coal into, the looseness of the formed coal is determined by the spring pressing the movable platen to press the coal tightly.

- The conveying part is composed of conveying frame, belt wheel, bracket, and conveyor belt. The conveyor belt rotates randomly to send the formed coal out of the machine, and the adjustable screw on the conveyor frame can adjust the tightness of the conveyor belt.

Contact us at any time

If you are interested in our honeycomb coal briquette production line and would like to know more details or experience our technology for yourself, please feel free to contact our sales team. We offer professional consulting services to meet your specific needs and can arrange for you to visit our factory. We look forward to building a relationship with you and providing you with superior honeycomb coal production solutions.