The sawdust briquette charcoal is a new type of charcoal made from biomass wood materials. Compared with traditional charcoal, it has the advantages of regular shape, flame resistance, and no dust explosion. After ten years of continuous innovation and improvement, the entire briquette charcoal production line has a reasonable equipment ratio connection, which can greatly reduce labor costs and improve production efficiency.

Moreover, this briquette charcoal production line can be customized according to customer requirements. It can be designed as a fully automatic production line or a semi-automatic production line, which has been widely praised by the majority of charcoal manufacturers.

Unlike the charcoal production line(related article: Charcoal-making production line), this line adopts the processing sequence of molding first and then carbonization. Therefore, after the sawdust briquette-making operation in the video above, the charring equipment is needed again to make the final charcoal briquettes.

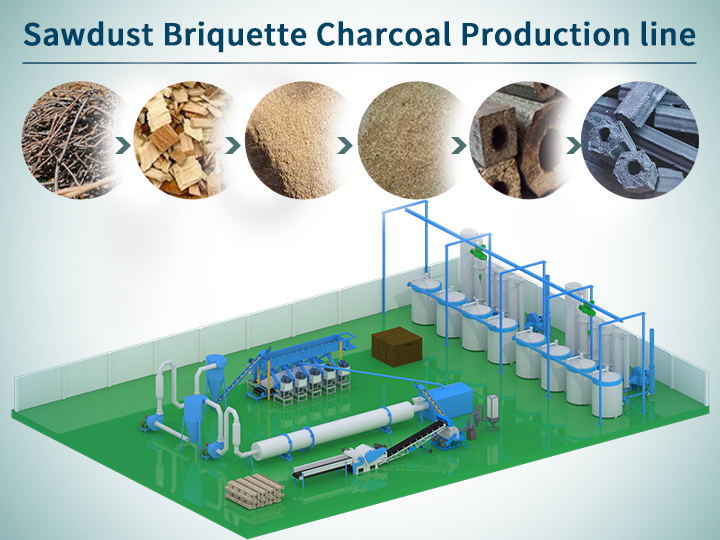

Workflow of sawdust briquette charcoal making line

The briquette charcoal production line mainly includes four major steps: crushing, drying, briquetting, and carbonization. The raw materials used in the sawdust briquette machine require fineness within 6mm, and the moisture content needs to be between 8%-12%. So the materials need to be crushed and dried first.

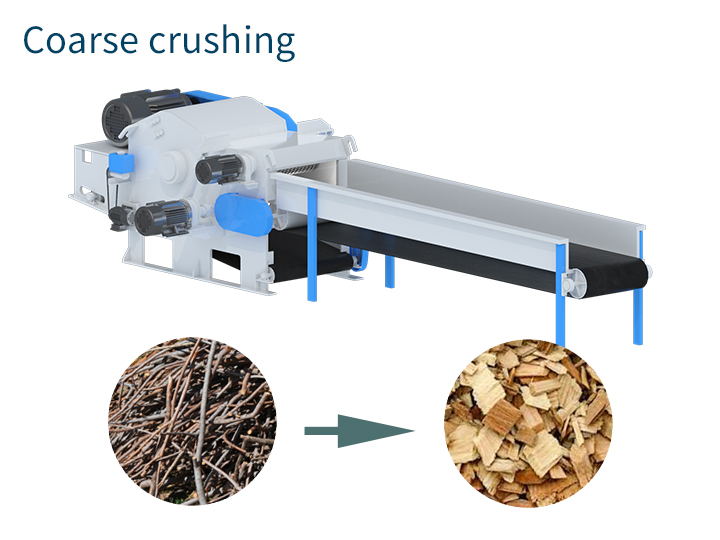

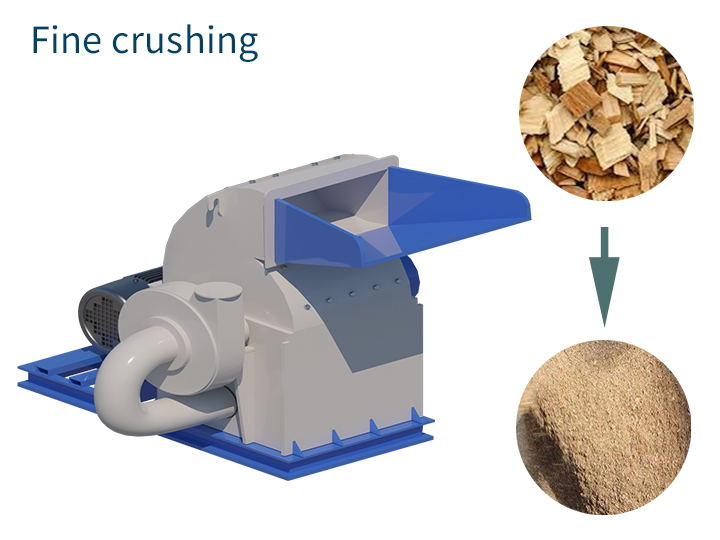

- Crushing: The crushing process mainly includes two processes: coarse crushing and fine crushing. The raw materials need to be crushed into 3-6mm sawdust powder.

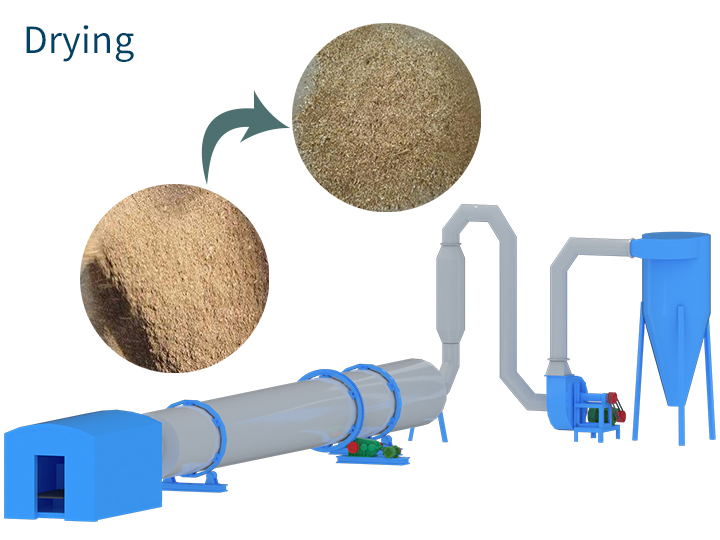

- Drying: The dryer is mainly to reduce the moisture in the material and reduce the moisture to 8%-12% according to the type of material. The dried materials need to be cooled before briquetting.

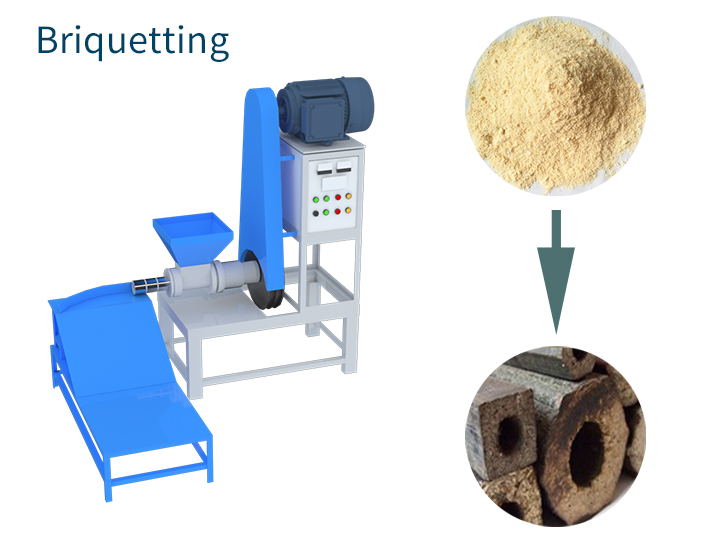

- Briquetting: This machine will make the material into briquette sticks of different shapes and lengths under high temperatures and pressure.

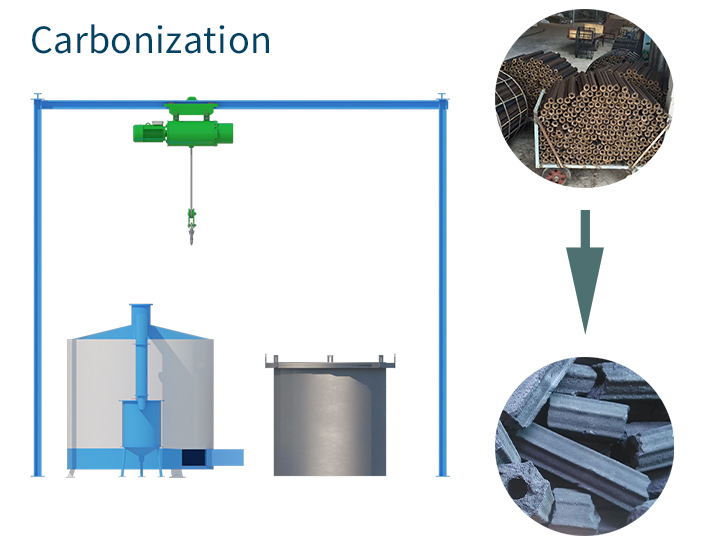

- Carbonization: The sawdust briquette will be carbonized under the high-temperature conditions of the carbonization furnace.

Main components of briquette charcoal production line

The briquette charcoal machine production line includes the wood crusher, sawdust dryer, briquette press machines, carbonization furnaces, and other auxiliary equipment.

Wood Crusher

The main purpose of this stage is to break large pieces of wood or woody raw materials into appropriate-sized particles to prepare for the subsequent briquette charcoal production line process. Through crushing, the surface area of the wood is increased, which is conducive to better subsequent processing steps, such as charring and molding, to improve charcoal production and quality.

Rotary Dryer

The airflow dryer is used to mix the wet materials with the high-temperature airflow, and finally, separate the water from the raw material through the separator.

Raw material enters the pipe through the inlet and is pumped into the cyclone by the wind fan and hot air.

The dried materials are released from the cyclone, and the waste heat and water vapor are discharged from the sand clones. Generally, it is used for sawdust drying in wood processing equipment and pellet drying in biomass pellet production.

Sawdust Briquette Machine

The biomass sawdust briquette machine can convert the wood chips and shavings, rice and peanut husks, bagasse, and other wood materials into hollow-rod solid fuel(Biomass Charcoal) under high temperature and pressure conditions.

This machine is mainly composed of the motor, control cabinet & control panel, feed port, forming cylinder, heating system, etc.

Carbonization Furnace

The carbonization of wood materials containing carbon under high-temperature conditions in the furnace. Our new type of carbonization furnace is mainly composed of the combustion chamber, carbonization liner, exhaust gas treatment device, waste heat utilization system, and crane system.

Heat Shrink Film Packing Machine

Finally, you can choose whether to use this packaging machine according to your needs, use the heat shrink film to wrap the charcoal tightly to protect the charcoal from the external environment, improve the appearance and quality of the product, and facilitate transport and storage.

Raw materials for briquette charcoal production

The raw materials of the briquette charcoal production line are extensive, including logs, branches, bamboo, shavings, coconut shells, rice husks, peanut shells, crop straws, and other wooden materials.

Show and application of finished products

The finished coal briquettes, which are processed through a briquette charcoal production line, are a common biomass fuel used for heating, cooking, and other energy needs. Due to its high combustion efficiency and large calorific value, it is widely used in households, industries, and rural areas.

Display of briquette charcoal production line

If you are interested in our briquette charcoal production line products or have any questions or needs about charcoal production, please feel free to contact our professional team. Meanwhile, we warmly welcome you to visit our factory. We provide diversified solutions and customized equipment to suit your production needs.