What Industries can benefit from a Wood Pallet Block Making Machine?

Wood pallet block making machines feature low investment costs and are widely used in logistics, transportation, wood processing, and export packaging industries.

Wood pallet block making machines feature low investment costs and are widely used in logistics, transportation, wood processing, and export packaging industries.

Wood shavings production machines efficiently process low-cost wood raw materials into highly absorbent animal bedding, significantly enhancing bedding quality while reducing production costs.

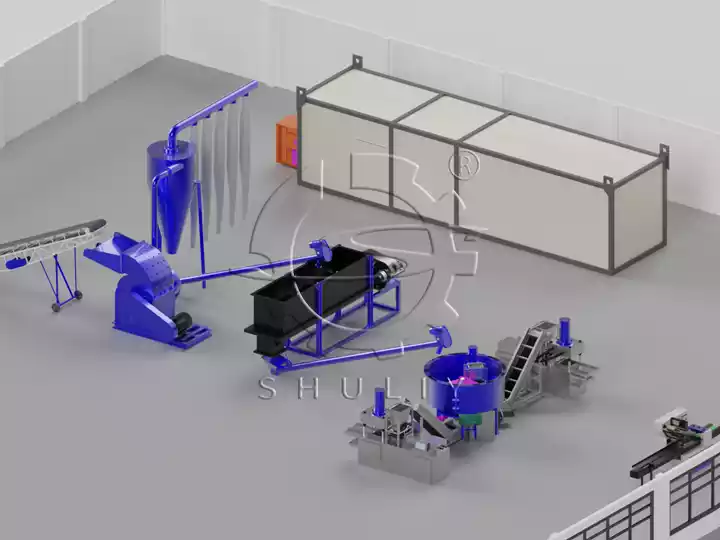

The charcoal briquette processing line offers flexible processing of multiple raw materials and a short investment payback period, making it an ideal choice for small and medium-sized entrepreneurs.

Investing in hookah charcoal production offers advantages of low costs, high efficiency, and stable market demand, enabling small businesses and entrepreneurs to achieve substantial profits.

This article outlines key reference factors for selecting the appropriate wood saw milling machine, helping wood processing users efficiently match equipment and enhance production capacity.

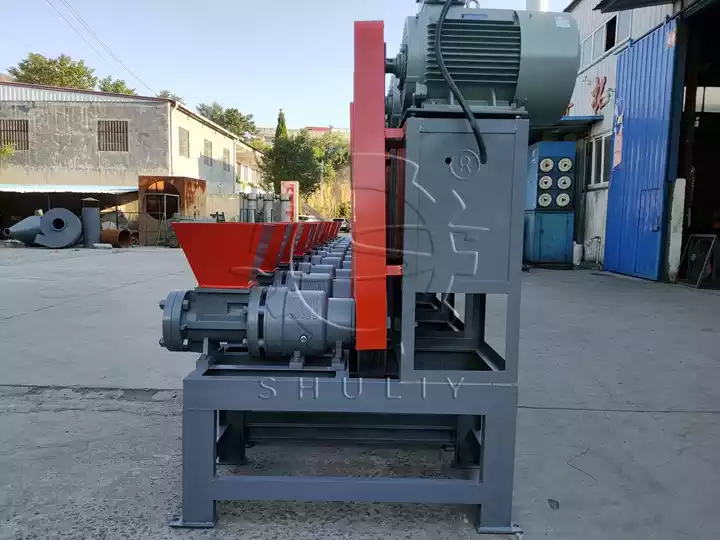

The sawdust briquette maker efficiently compresses waste materials such as sawdust and straw into fuel briquettes. Its price varies based on production capacity, automation level, and machine material.

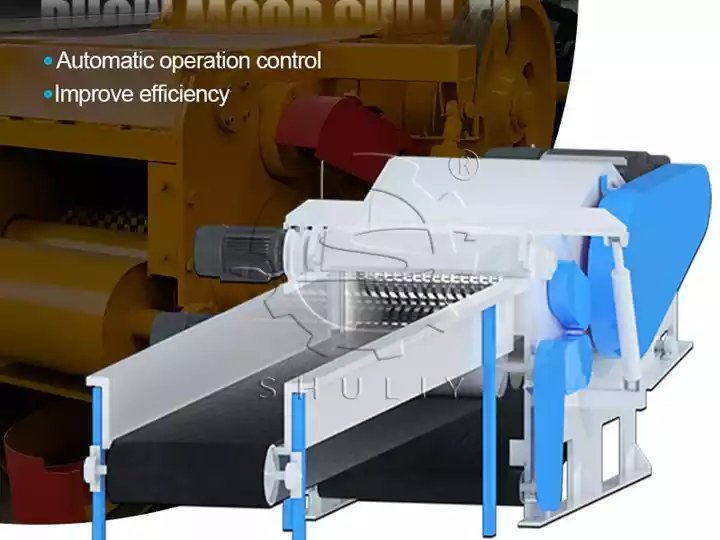

The comprehensive crusher machine delivers powerful performance and broad applicability, efficiently processing wood, agricultural waste, and industrial offcuts to achieve multi-material crushing.

Sawdust pallet block machines, featuring high precision and heavy-duty load capacity, are suitable for wood processing, furniture manufacturing, logistics warehousing, industrial transportation, and agricultural pallets.

The wood chipper effortlessly processes thick branches and whole logs with its powerful drive system and automatic feeding technology, achieving efficient chipping and resource recycling.

End of content

End of content