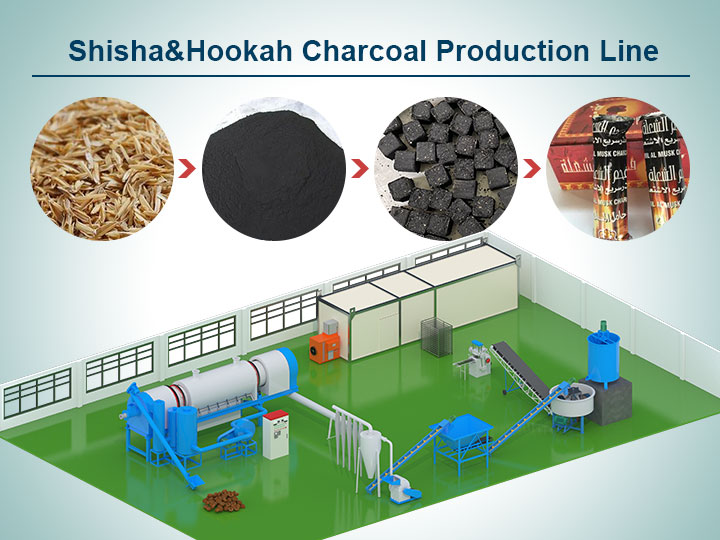

Shisha charcoal is a kind of charcoal specially used for smoking water pipes, and it is very popular in many countries. As an expensive consumable, hookah charcoal has huge market potential. Our company has recently launched a new set of fully automatic hookah charcoal production lines, which can meet the needs of customers for high-efficiency and high-quality production of hookah charcoal. The produced hookah charcoal has the advantages of being hard and non-divergent, high density, easy to ignite, long burning time, uniform heating, etc. Our hookah charcoal production line mainly includes the carbonization furnace, charcoal block crusher, hookah charcoal briquette machine, drying room, packing machine, and other auxiliary machines. According to customer needs, our hookah charcoal production line can also be customized as a fully automatic or semi-automatic production line, the size and shape of the hookah charcoal can also be customized according to customer needs.

What is shisha charcoal?

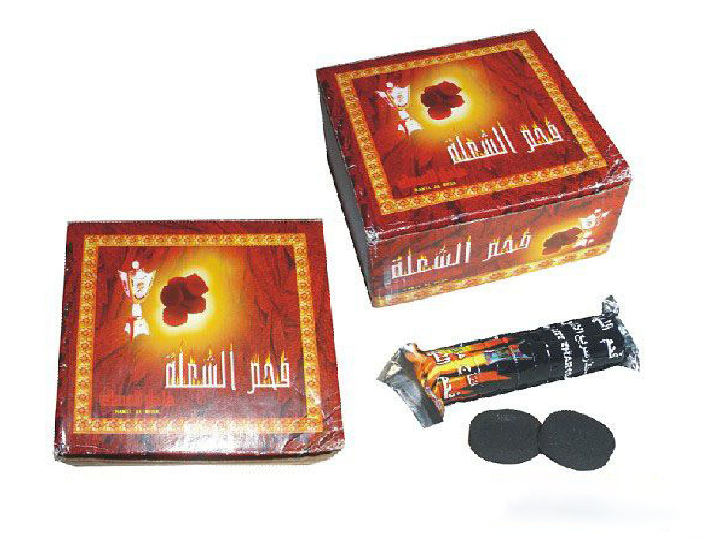

Shisha charcoal is the charcoal used to smoke a hookah. In the United Kingdom and the United States, people call it Hookah, and in European countries, it is called Shisha. In fact, her big name in Arab countries is Nargile. Generally, a small piece of charcoal can burn 50 It lasts from minutes to an hour, and emits a fragrance during the burning process. It is a green and environmentally friendly product.

What is shisha charcoal made of?

There are many materials for making hookah charcoal, which can be coconut shell, bamboo, fruitwood, sawdust, or corn stalks in the agricultural production process. But the raw material for making hookah charcoal is coconut shell. The shisha charcoal produced from coconut shells is strong, non-breakable, economical, and durable.

Hookah charcoal production process

The production of hookah charcoal mainly includes the steps of carbonization, crushing, mixing, molding, and drying.

- Carbonization: First, the raw materials need to be carbonized. Generally, harder raw materials such as fruitwood and coconut husk are carbonized by a hoisting carbonization furnace, while materials with smaller particle sizes such as rice husk, straw, and wood chips are used for continuous carbonization furnace.

- Crushing: The carbonized material needs to be crushed into 3-5mm carbon powder to facilitate subsequent molding. For high-quality hookah charcoal, the Raymond mill is generally used for further refinement, and the final product will have a better quality this way.

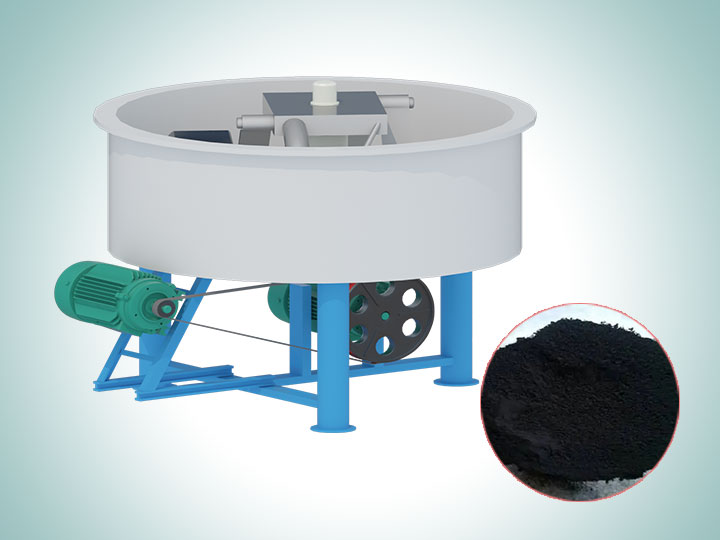

- Glue mixing: Before molding, the crushed carbon powder needs to be mixed with the binder. A certain proportion of carbon powder and binder are added to the wheel mill through the quantitative silo. After sufficient mixing and grinding, the forming process can be started.

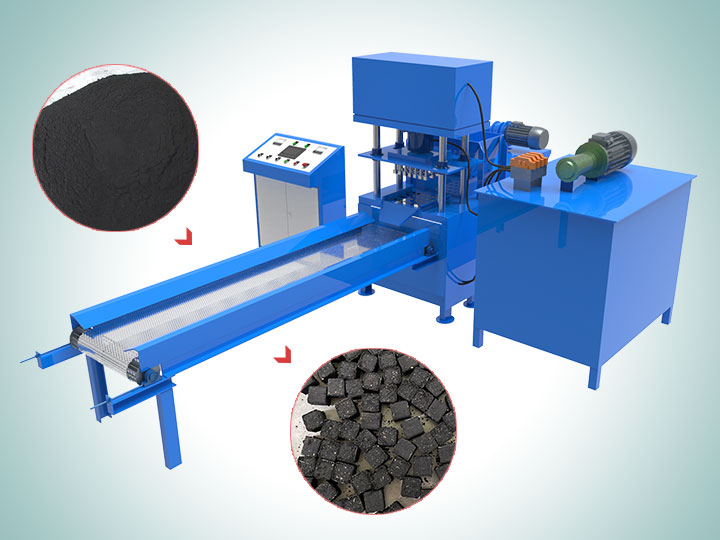

- Forming: Put the processed raw materials into the hookah charcoal briquetting machine. Choose the suitable mold, set the size and other parameters, and then you can press the hookah charcoal.

- Drying: The pressed shisha charcoal still contains a certain amount of moisture and needs to be dried. The dried hookah charcoal can be packaged and sold.

High-quality hookah charcoal judgment criteria

- Density.The burning time of hookah charcoal is not only related to the raw material and size, but also has a close relationship with the density of hookah carbon. The higher the density of hookah carbon, the longer the burning time. Generally speaking, the proportion of good hookah charcoal exceeds 1.3.We can also test it through a small experiment: fill a cup with water, and then put the shisha charcoal in. If the shisha charcoal sinks to the bottom of the water, it means that its specific gravity is greater than 1, and it is a qualified shisha charcoal. After the hookah charcoal enters the water, it can be kept in good condition for a long time. If it dissolves and turns into carbon powder in a short time after entering the water, it means that the quality is very poor. Through such a small test, the quality of the hookah charcoal can be easily detected.

- Hardness.The hardness refers to two aspects. Before burning, the hookah charcoal is not easy to break. You can pick up the hookah charcoal and throw it from a distance of 1 meter from the ground to see the degree of shattering of the hookah charcoal. Another aspect of hardness is that the hookah charcoal should not disperse after the hookah charcoal is burned. The hardness of hookah carbon is also a very important indicator.

- Combustion temperature.High-quality hookah charcoal not only has a long burning time, but also has a certain standard of burning temperature. The burning temperature needs to be constant, the surface temperature is 320 °C, and the intermediate temperature of hookah charcoal is 350 °C. When burning, it emits the fragrance of fruit wood, and there is no other peculiar smell.

- Ignition time.The ignition time generally requires about 7 minutes to ignite, and it is flammable, even if it is ignited with a piece of wood, so it does not need to wait too long when using it.

- Dust.The size of the dust has an important relationship with the binder in the processing of hookah charcoal. The ash content of high-quality hookah charcoal does not exceed 6%. At the same time, many customers simply think that if the ash after the hookah charcoal is burned is white, this is the Good hookah charcoal, in fact, the color of hookah ash is directly related to the raw material, but it cannot be said that it is directly related to the processing technology of hookah charcoal.

Main components of the shisha charcoal production line

The hookah charcoal production line mainly includes the carbonization furnace, charcoal crusher, wheel mill, hydraulic hookah charcoal briquette machine, drying room. In the entire production line, an electric control cabinet and multiple spiral conveyor belts are also required. According to customer needs, the Raymond mill, quantitative silo, hookah charcoal packing machine can also be selected. The output of the entire production line can reach 2-3t/h.

Continuous carbonizing furnace

The continuous carbonization furnace can make wooden materials like wood sawdust or peanut shell into charcoal. This equipment can continuously carbonize for 24 hours, realizing simultaneous feeding and discharging. It is the ideal equipment for the mass production of charcoal.

Charcoal crusher

The industrial charcoal crusher is mainly used for crushing all kinds of charcoal or coal briquettes into small pieces and powder. With high efficiency for grinding charcoal and coal powder, this coal crusher is widely used in charcoal processing plants and various charcoal production lines. rusher is mainly used for crushing all kinds of charcoal or coal briquettes into small pieces and powder. With high efficiency for grinding charcoal and coal powder, this coal crusher is widely used in charcoal processing plants and various charcoal production lines.

Wheel mill

The wheel mill is a kind of grinding equipment with the grinding wheel and grinding disc as the main working parts. The material is pulverized by the grinding wheel on the rotating grinding disc. The outer ring of the grinding disc has sieve holes, and the pulverized material is discharged from the sieve holes.

Hydraulic hookah charcoal briquetting machine

The hookah charcoal tablet press is a kind of carbon powder molding equipment, which uses high pressure to press the carbon powder into carbon blocks of different shapes. The hookah charcoal tablet press is widely used in carbon powder and coal powder forming and is essential equipment in the process of carbon powder processing.

Auxiliary equipment in the hookah charcoal production line

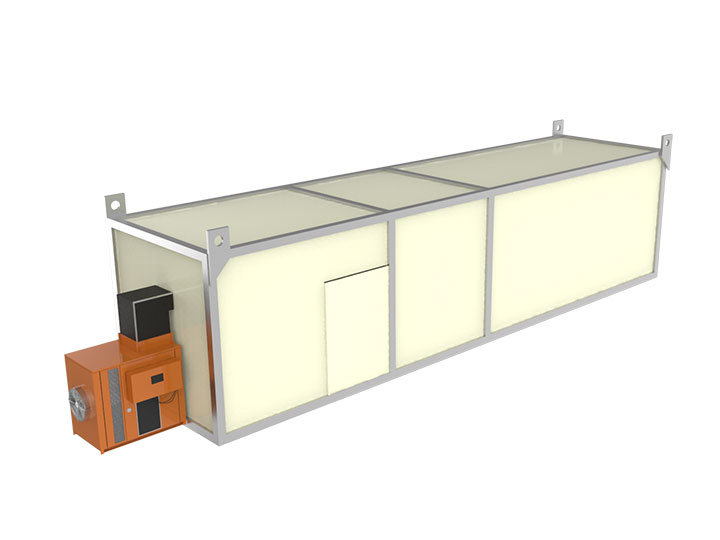

Drying room: It is better to use the drying room to dry the hookah charcoal. Because the Shisha charcoals are placed in stationary trays, which are not prone to cause damage during the drying process.

Raymond mill: The Raymond Mill can further crush the crushed materials, and the fineness can reach 30-325 mesh. It can make the molded hookah charcoal more compact and have better quality.

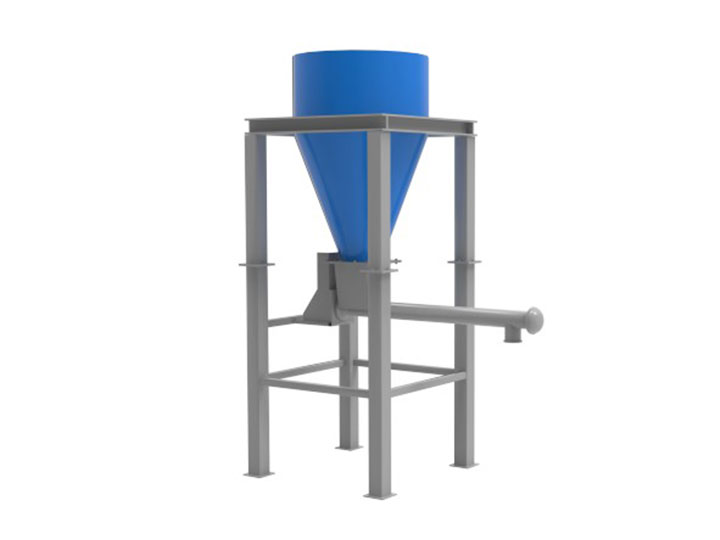

Quantitative silo: The quantitative funnel can mix a certain amount of materials and adhesives together, which is conducive to achieving a perfect ratio and obtaining a better molding effect.

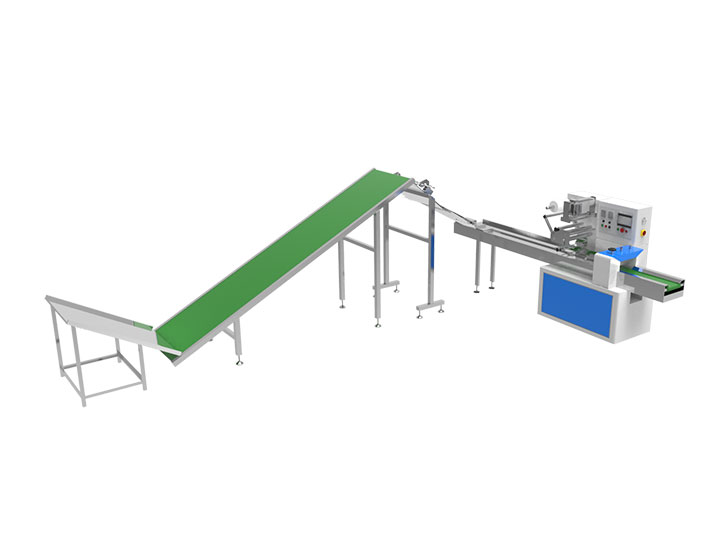

Hookah charcoal packing machine: The hookah charcoal packaging machine can realize automatic classification, sorting, and packaging, which is convenient for subsequent collection.

Advantages of shisha charcoal production line

- The equipment is easy to operate and easy to maintain. The whole production line adopts a fully automatic electronic control system, and the entire production line can be operated by only one person, saving manpower.

- The raw materials are highly adaptable, it can be hard-textured types such as coconut shell charcoal, bamboo charcoal, and fruit charcoal, or rice husk, straw, wood chips and other fine-grained types.

- The entire production line can be selected according to customer needs, and the size and shape of the finished hookah charcoal can be customized. The factory is equipped with a variety of molds such as round, triangle, hexagonal, square, plum blossom, etc., which can produce various types of finished charcoal such as hookah charcoal, finger charcoal, gift charcoal, charcoal rod and so on.

- The finished shisha charcoal has the advantages of being hard and non-divergent, high density, easy to ignite, long burning time, uniform heating, etc. The final product can meet the market demand for high-quality hookah charcoal.

- To help customers achieve profitability as soon as possible, the company provides free adhesive formulations, various hookah charcoal processes, teaching videos, etc.