BBQ charcoal production line is the equipment used to process coal balls, the production line includes a carbonization furnace, crusher, screw conveyor, mixer, and spherical charcoal forming machine. It is a complete set of equipment, from raw material carbonization to charcoal forming with corresponding machines. The barbecue charcoal production line has been sold to Saudi Arabia, Iran, Egypt, Libya, South Africa, and other regions.

BBQ charcoal production line raw materials

Barbecue charcoal production line raw materials can be coal powder, after mixing with a binder directly into shape, but also coconut shells, wood, rice husk, peanut shells, bamboo, etc., the use of raw materials for processing needs to be carried out to carbonize these raw materials, crushed, mixed with a binder, and then in the molding.

BBQ charcoal production line production process

The raw materials used are put into the carbonization furnace and then carbonized. We have three types of hanging carbonization furnaces, horizontal carbonization furnaces, and continuous carbonization furnaces, according to the material processed and the output to choose from. The continuous carbonization furnace type is relatively large, with automatic discharge and feeding.

A Hammermill machine can crush the charcoal after carbonization, but the crushing is not particularly fine and needs to be ground again.

Raymond Mill can further grind the carbon powder to make it finer and produce barbecue charcoal with a longer burning time and better effect.

After crushing and grinding the toner, it can be put into the wheel grinder mixer, add water and binder in the machine, mix, and stir.

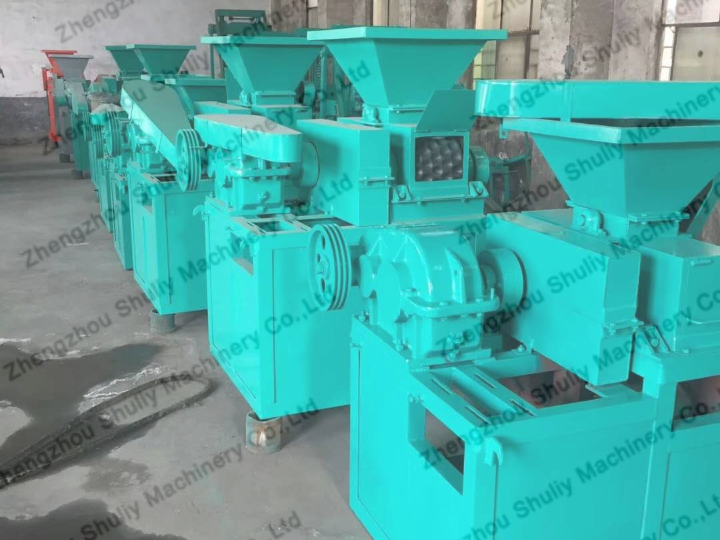

BBQ charcoal forming machine produces mixed raw material of carbon powder can be formed, and the shape can be customized according to the demand because the mold of the carbon ball press can be customized, so a variety of carbon balls can be produced.

Advantages of charcoal ball extruder machine

- Diversification of molds. The BBQ charcoal production line can produce various shapes of barbecue charcoal.

- High ball formation rate. Good density and high strength of finished products with low breakage rate.

- Wide application, can press coal powder, coal powder, sawdust, and mineral powder.

- The high degree of automation can adjust the working speed.

- Many models. There are many models of ball press machines, you can buy the machine according to the output.

Why can benefit from producing barbecue charcoal

- Small investment and large processing capacity of coal briquetting equipment. It can handle tens of thousands of tons of materials per day and can be produced continuously;

- Simple operation, the whole BBQ charcoal production line. The conveyor and control system control, the intermediate link without manual operation, saving time and labor.

- Little pollution. With energy-saving and environmental protection molding systems, reduce the pollution caused by dust and noise caused by the production.

- High revenue. Barbecue carbon raw materials are cheap and simply available, barbecue carbon prices are high, the middle difference is large, and there are obtainable profit points.

Components of coal ball press machine

- Feeding system – To achieve quantitative feeding to ensure uniform feeding of iron powder.

- Supporting motor – Iron powder ball press machine electromagnetic speed control motor constant torque characteristics, when the feeder pressure material and the amount of iron powder required by the host equal, can maintain a constant supply pressure to make the quality of the pellets stable.

- Transmission system – The transmission part of the iron powder pellet press has an electric motor – triangle belt -reducer – open-gear – rollers composition.

- Hydraulic protection device – When the iron powder pellet press is working, the hydraulic pump will pump high-pressure oil into the hydraulic cylinder to make the piston produce axial displacement, and the front joint of the piston rod is on the bearing seat to meet the production pressure requirement.

Video of charcoal ball making machine

If you are interested in our equipment or have any questions about the BBQ charcoal production line, feel free to contact our professional team. Our staff will be happy to provide you with detailed product information, technical support, and customized solutions. Further, we sincerely invite you to visit our factory, so that you can have a more comprehensive understanding of our production process and ensure that your purchasing decision is more informed.