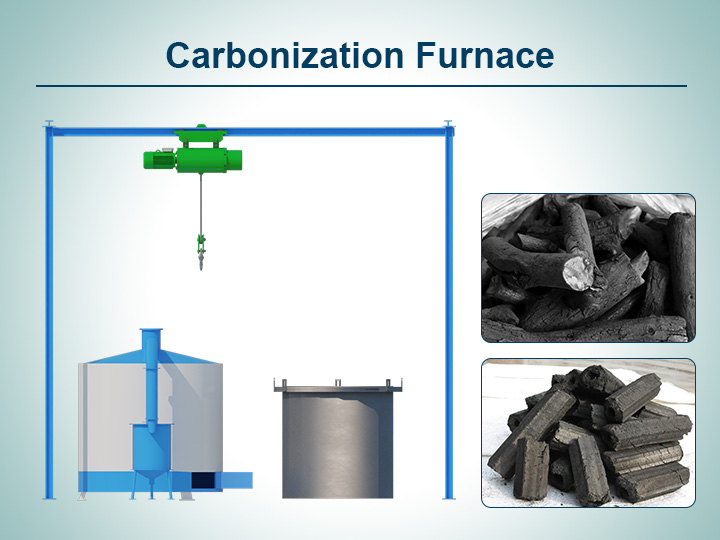

The hoisting type carbonization furnace is an environmentally friendly device specifically designed for the high-temperature pyrolysis carbonization of wood or plant-based carbon-containing raw materials. It is widely used in the charcoal production of medium to large-scale charcoal enterprises.

This equipment adopts a suspended modular structure and advanced hot gas carbonization technology, recycling and reusing the combustible gases generated during the carbonization process. This achieves self-sufficient thermal energy, energy conservation, and environmental protection, effectively addressing the issues of high pollution and energy consumption associated with traditional carbonization furnaces.

Each carbonization cycle lasts approximately 7–8 hours, with a daily production capacity of 1–3 tons, making it an ideal choice for large-scale continuous charcoal production.

We have two other types of machines available, including horizontal charcoal furnaces and continuous charring furnaces.

What are the materials that can be carbonized?

The hoisting type charring furnace is suitable for the carbonization treatment of various plant-based raw materials, including but not limited to:

- Logs, wooden sticks, large branches, hardwood, bamboo.

- Sawdust sticks, wood chip compressed sticks (for use with a charcoal stick machine).

- Coconut shells, walnut shells, palm shells, peanut shells, rice husks, bark, straw, and other carbon-containing agricultural and forestry waste materials.

Compared to continuous-type carbonization furnaces, this equipment has greater adaptability to raw material sizes, making it particularly suitable for carbonizing large-volume, irregularly shaped wooden materials.

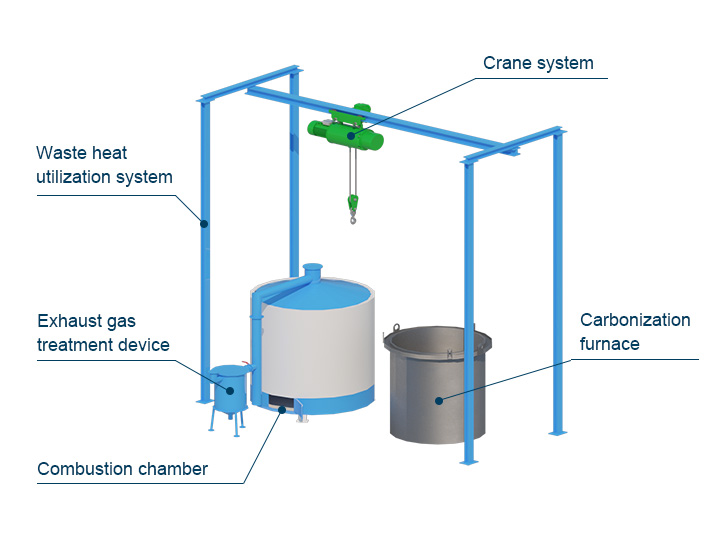

Structure of hoist carbonization furnace

Our new type of carbonization furnace is mainly composed of the combustion chamber, carbonization liner, exhaust gas treatment device, waste heat utilization system, and crane system.

This machine adopts the new structure of separating the carbonization furnace and combustion chamber, it adopts the movable installation of the carbonization furnace.

The furnace’s cooling is carried out outside the combustion chamber, so it can realize continuous work and greatly shorten the production cycle. The combustion chamber can be equipped with multiple carbonizing furnaces, and it doesn’t need to do the preheating treatment after the replacement of carbonizing furnaces. This will greatly improve the efficiency of carbonization work, and save energy and labor.

Hoisting type carbonization furnace working process

The carbonization of materials is mainly divided into three stages: the drying stage, the initial stage of carbonization, and the full carbonization stage.

- Drying stage (0–160°C): after ignition, the furnace temperature gradually rises, and the moisture in the raw materials is evaporated, but the composition of the materials themselves does not change significantly.

- Primary carbonization stage (160–280°C): the materials begin to pyrolyze, releasing CO₂, CO, small amounts of acetic acid, and other substances, and the structure of the wood begins to change.

- Complete carbonization stage (300–650°C): the material undergoes intense decomposition, producing liquids such as wood tar, acetic acid, and methanol, as well as flammable gases like methane and ethylene. These gases burn within the furnace, raising the temperature, and ultimately distilling the wood into high-quality charcoal.

To further improve charcoal quality, the furnace temperature can be raised to 800°C–1000°C to remove volatile substances, increase carbon content and conductivity, and produce high-temperature carbon or conductive carbon materials.

Advantages of the charcoal carbonization furnace

- Energy-saving and environmentally friendly: the combustible gases generated during the carbonization process are subjected to spraying, cooling, and purification before undergoing secondary combustion, enabling self-sufficient thermal energy supply, reducing fuel costs, and eliminating direct exhaust emissions, thereby meeting environmental emission standards.

- Rational structure and continuous operation: adopting a modular design, a single combustion chamber can be paired with multiple carbonization chamber liners for alternating use, with cooling and carbonization occurring simultaneously, significantly shortening the production cycle and enhancing carbonization efficiency.

- Labor-saving operation: a hoisting material handling system, paired with a crane of ≥2 tons, enables easy and quick material loading and unloading, significantly reducing labor costs and physical strain.

- Long service life: the inner chamber is made of high-temperature wear-resistant materials, featuring strong heat resistance and resistance to deformation, ensuring durability and low maintenance costs.

- Automatic temperature control and safe efficiency: equipped with a flue gas recovery chamber and temperature control system, it effectively regulates carbonization temperature and time, ensuring carbonization quality and operational safety.

- High time utilization: standard configuration includes two inner chambers, enabling simultaneous cooling and carbonization, achieving continuous operation with alternating workflows, ensuring more reliable production output.

Hoist carbonization furnace technical parameters

| Model | SL-1500 |

| Output capacity | 2500-3000kg/24 hours (Depends on the materials) |

| Loading capacity | 2600-3000kg/per 8 hours |

| Carbonization time once | 8hours |

| Dimension | 1940x1900x1900mm |

| Steel thickness | 6mm |

| Inner stove size | 1.5×1.5m |

| Weight | 2.8kg |

| Including parts | One machine includes 3 stoves |

| Electricity power | No need for additional power |

| Biomass cost for heating per 8 hours | 50-80kg waste biomass per 8 hours |

Related video about carbonization furnace

Hoisting charring furnace successfully operating in Guinea

We exported a charcoal production line to Guinea. The carbonization furnace used by the customer is this lifting carbonization furnace. Our engineers returned after installing and testing successfully in the customer’s factory. After installation, train the factory workers to ensure the smooth operation of the factory.

At the end of this presentation, we hope that you have gained a better understanding of our hoist carbonization furnace. If you are interested in our products, please feel free to contact us, and we will provide you with professional purchase service.