This charcoal carbonization furnace is large-scale carbonization equipment. Compared with other carbonization furnaces, it has a stronger carbonization function, a wider range of materials that can be carbonized, and continuous production with higher production efficiency. This machine has not only a large output that can produce 3 tons/hour but also a small model of 500kg/h.

Biomass charcoal-making machines are most commonly used in the production of carbon and rice husk carbon and are often used in hookah carbon production lines and barbecue carbon production. Moreover, our carbonization furnace machines are so popular that they have been shipped to the following countries such as Germany, Iran, Japan, and Malaysia.

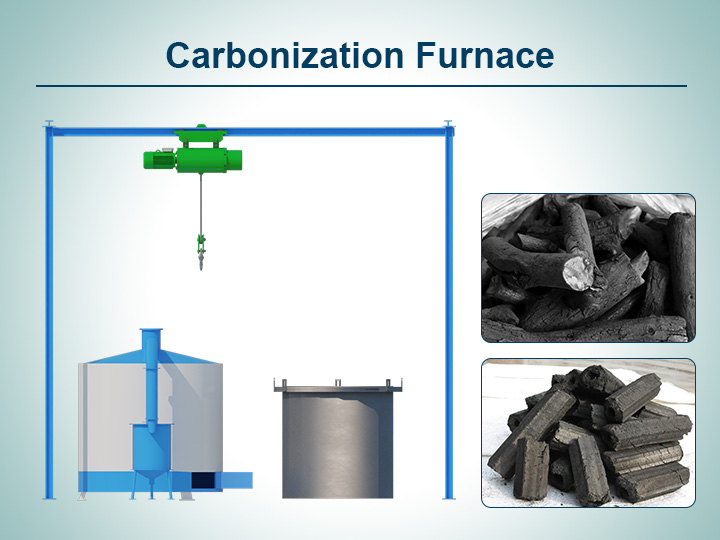

The other two types of charcoal ovens shown in the video above(hot-selling hoist-type charcoal carbonization furnaces and horizontal charring furnaces) are listed below, so you can choose according to your needs.

Raw materials for charcoal carbonization furnace

For this carbonization furnace, all products containing carbon can be carbonized, especially some kitchen waste, waste clothes, animal manure, and even river sludge can be carbonized. Specific common materials include straw scraps, rice husks, straw, sawdust, nutshells, bark, bamboo powder, bamboo chips, branches, tree roots, coconut shells, jujube stones, peels, cow bones, cow dung, etc.

Biomass charcoal making machine processing conditions

The humidity is below 25%. If there is too much moisture, it needs to be dried first. The fineness of the material is 20mm. If the material is too large, it needs to be crushed first. The general carbonization time is 18-20 minutes, and a batch can be carbonized in about 20 minutes, and the production efficiency is very high.

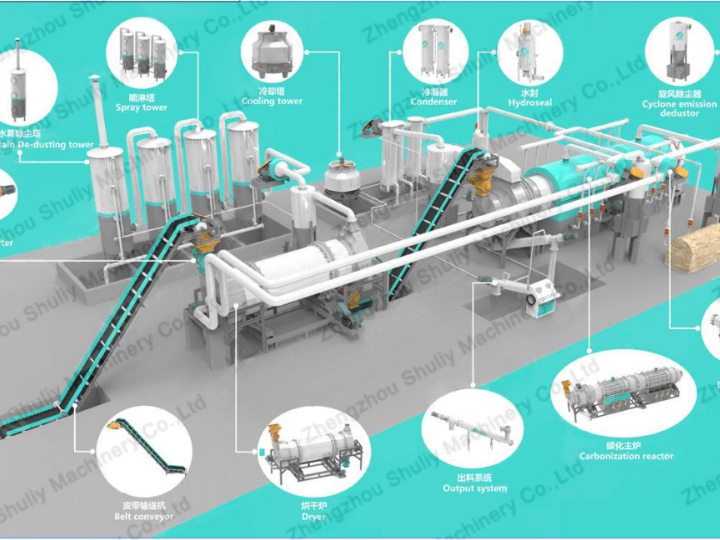

Charcoal carbonization furnace main structure

The basic structure of the machine includes a charcoal carbonization furnace, gasification furnace, soot processor, combustible gas purifier, and an intelligent numerical control panel added to its console.

Biomass charcoal making machine parameters

| Model | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | continuous carbonizing | continuous carbonizing | continuous carbonizing | continuous carbonizing |

| Reactor Size | 800mm | 1000mm | 1300mm | 1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. |

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Cooling Method | Recycling Water Cooling | Recycling Water Cooling | Recycling Water Cooling | Recycling Water Cooling |

This machine is larger, but there are also different models, the smallest model is SL-0812, which can produce 500kg, and the largest model is SL-1320, which can produce 2.5-3Tons, The material can be discharged immediately after production, which is convenient and efficient.

Charcoal carbonization furnace advantages

Smokeless carbonization design

Adopting a new innovative structure, the combustion exhaust gas can be discharged up to the standard, and the combustion flue gas can be fully utilized to achieve smokeless carbonization during the operation process.

Continuous operation and large-scale production

The continuous carbonization furnace overcomes the disadvantages of the traditional batch carbonization furnace, and through innovation, it can carry out efficient continuous production. Taida’s new charcoal carbonization furnace is based on the drum carbonization furnace and iteratively upgrades to help users achieve large-scale production.

Priority material and life guarantee

The combustible combustion system adopts high-frequency welding, and the heating shell is lined with high-temperature refractory fiber, which has a long service life and burning wearing parts, which makes users more worry-free.

Low energy consumption and green production

The production process of carbon/gas/oil co-production is realized, and the traditional defects of high energy consumption/high pollution/low efficiency are solved. In the carbonization process, tar/wood vinegar and combustible gas are all recovered and reused.

Successful cases of the Shuliy carbonization furnace design scheme

After learning about the needs of Iranian customers to carbonize sludge, Shuliy Company helped customers make a feasible plan, including sludge dewatering, sludge drying, and sludge carbonization. The carbonized sludge can be used for Soil improvement, processing, and production of filling materials and construction, etc., the biggest advantage of this carbonization equipment is the diversification of products that can be carbonized.

How do use carbonization equipment to make profits

The carbonized products can be sold directly so that the production investment is small and the return on cost is fast. In addition, it can be processed further after carbonization, such as processing into hookah charcoal and barbecue charcoal. The deep-processed products are highly profitable.

Since the carbonization furnace is the basis for the production of carbon products, the sales volume of the carbonization furnace has always been the star product of Shuliy Machinery Co., Ltd. Welcome to watch and learn more about our leading charcoal carbonization furnace technology, and feel free to contact us for more details!