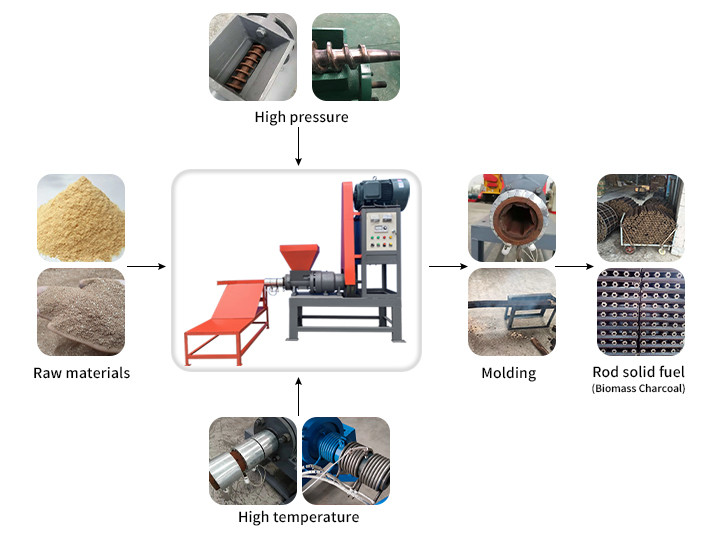

The sawdust briquette charcoal is a kind of high-energy clean fuel, the quality is better than traditional fired charcoal. The quality of the briquette charcoal made from different raw materials is significantly different. Raw materials rich in lignin and high in cellulose mixed in a certain proportion can produce high-quality briquette charcoal. Therefore, as long as we strengthen scientific management and pay close attention to the scientific combination of raw materials, we can improve the efficiency of resource utilization and enable enterprises to obtain better benefits.

Raw material requirements for briquette charcoal making machine

- Requirement of raw material moisture: Generally, the moisture content of raw materials is required to be less than 10%. Therefore, the first step is to dry the raw materials. During the drying process, we can first put the raw materials with higher moisture content in the open-air drying yard for 1 to 2 days to let the surface moisture evaporate to reduce the drying time and Fuel consumption. Then put the raw materials with qualified particle size into the hot air dryer and dry raw materials with a moisture content of less than 10%. The drying temperature is generally about 140 ℃ ~ 300 ℃.

- Temperature requirements: The briquette charcoal making is completed in the forming cylinder. There is a heating ring outside the forming cylinder which can increase the temperature to about 350°C. To ensure that the surface of the briquette charcoal is smooth, dense, and crack-free, we can choose the appropriate molding temperature according to the type of raw material and the moisture content.

- Requirements for accessories: The propeller of the briquette charocoal making machine is also called the screw and it is a vulnerable part. Its size can affect the speed and stability of the briquette charcoal making. Therefore, when the propeller is worn out, it should be replaced and repaired in time, so as not to affect normal production. When repairing, the wear-resistant welding rod must be used. The welded propeller should not have defects such as slag inclusions and pores.

Common problems and solutions

- The rod making machine does not produce rods: The reason is that the heating temperature is too high or too low, the forming sleeve of the rod making machine is worn more seriously, the angle of the screw propeller is not consistent, and the raw material moisture is too large. Our company’s charcoal machine adopts automatic temperature control device, and the molding sleeve is made of high-alloy material, which is compressive and wear-resistant.

- The fuel rod does not form: Most situation are caused by the improper temperature control, excessive moisture in the raw material, worn out of the propeller of the rod making machine, improper shaft tip, clogged vent hole, too large or too small screw of the head of the rod making machine’s propeller, and sleeve Serious wear, etc.

- The quality of salary stick is not high: Excessive moisture in the raw material will easily cause transverse cracks in the bar, and too little moisture will easily cause longitudinal cracks. In addition, the heating temperature is too high, the raw material will be excessively softened, resulting in insufficient material supply, which will also lead to the generation of cracks. If the feed barrel is insufficiently supplied, the diameter of the spiral can be appropriately increased, or the spiral wall can be polished to increase the pitch between the spirals.

Proper maintenance is the effective way to extend the life of the briquette charcoal machine

For the maintenance of the briquette charcoal machine, it is not simple maintenance, there must be certain methods and tricks. We have to divide the main and secondary to carry out each link of the equipment carefully. The charcoal machine equipment has one in the early stage of work. During the running-in trial period, later maintenance and maintenance are required after normal operation. Although the charcoal machine equipment is not a precision instrument, the maintenance of the equipment still needs attention. Among the charcoal machine equipment, the most need to maintain is the vulnerable parts of the equipment, such as the screw of the propeller, the barrel of the rod-making machine, the inner sleeve, and so on. As long as we have to master the correct methods and technical essentials to operate, then maintaining the charcoal machine equipment is still very simple. Do a good job in the maintenance of the above charcoal machine, not only can successfully complete the task of making charcoal but also can greatly improve the quality and efficiency.