We have completed the container loading and shipment of a wood timber peeling machine, which is now en route to Ukraine. The customer is a company specializing in primary wood processing and supplying semi-finished furniture components, holding a strong competitive position in the local market.

Customer background and needs analysis

In recent years, driven by increased timber export demand and furniture industry upgrades, the client recognized the inefficiency and high costs of traditional manual debarking methods. There was an urgent need for efficient, stable mechanized equipment to replace manual labor.

After thorough comparisons and evaluations, the client selected our wood debarking machine, aiming to enhance overall production capacity and product quality through advanced technology.

Wood timber peeling machine specifications

The shipped wood debarking machine features the following specifications:

- Production capacity: 10 meters/minute

- Power: 7.5kW + 2.2kW

- Suitable log diameter: 80-320mm

- Machine dimensions: 2.45 x 1.4 x 1.7m

- Packaging dimensions: 2.26 x 2 x 1.3m

- Weight: 1800kg

The equipment also features customizable blades that can be flexibly adjusted according to different wood types and processing requirements. Utilizing an efficient transmission system and rational blade design, the wood debarking machine ensures uniform debarking while effectively minimizing surface damage to the wood.

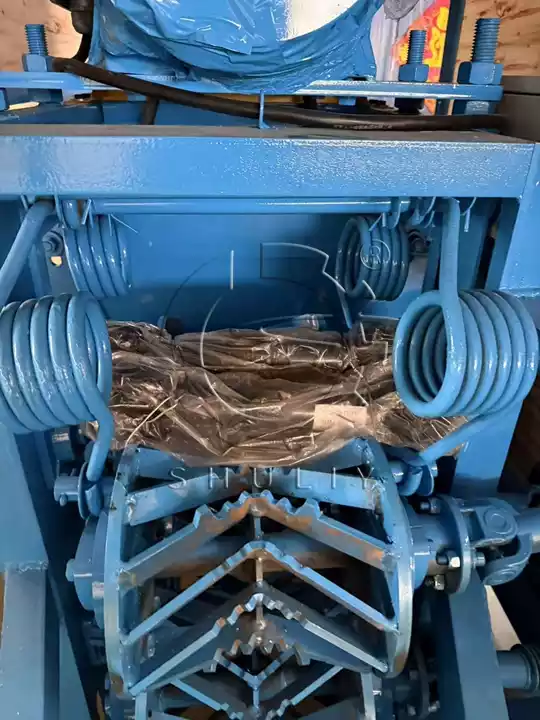

Container loading and shipment site

At the factory shipment site, technicians conducted comprehensive debugging and meticulous inspections of the equipment, followed by trial runs to ensure optimal operational status.

Workers then securely fastened the wood debarker onto wooden pallets according to export shipping standards, reinforcing critical areas with protective packaging to prevent impacts and vibrations during transit.

After the equipment was successfully loaded into the container, our company provided the customer with spare blades, detailed operating instructions, and maintenance manuals. We also shared installation and commissioning video materials to help the customer quickly get started upon receiving the equipment.