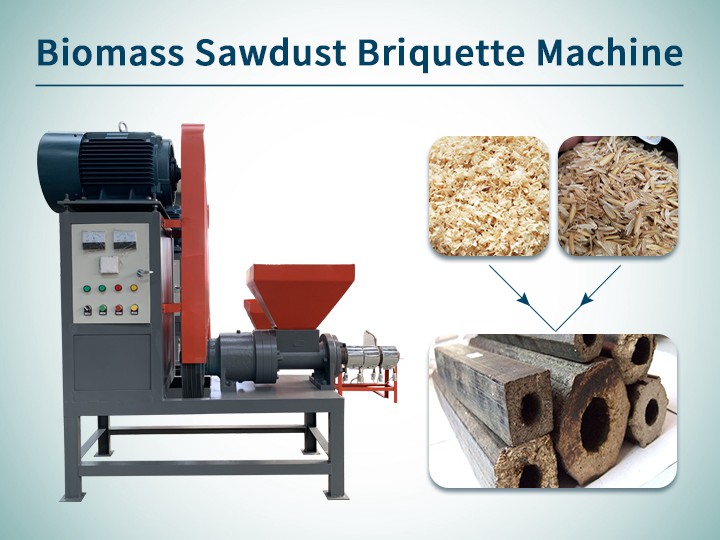

The biomass sawdust briquette machine adopts high-temperature and high-pressure binder-free molding technology. It can press agricultural and forestry wastes such as sawdust, shavings, rice husk, peanut shells, bagasse, etc., into hollow stick biomass fuel with a density of 1.0-1.4g/cm³.

Compared with ordinary wood, the sawdust briquette is easier to ignite, the calorific value is increased by more than 20%, the pollution is lower, and the density is higher. It is easy to store, transport, and burn for a long period of time, providing an economical and practical clean energy solution for agricultural and forestry waste.

Raw materials and applications of biomass briquettes

The biomass fuel sawdust briquette machine is suitable for many kinds of agricultural and forestry wastes containing lignin, mainly including:

- Wood chips, bamboo chips, shaving

- Rice husk, peanut shells, corn cobs

- Cotton stalks, crop stalks, orchard and garden pruning branches

- Bagasse, coconut shell, furniture factory, bamboo products factory, chopstick factory edge waste, etc.

Raw material requirements: particle size ≤ 5 mm; moisture content ≤ 12%. (Wood chip crusher and drum rotary sawdust dryer can be used for pre-treatment)

Wood sawdust briquette extruder finished product

The biomass fuel rods made by the sawdust briquette machine are widely used in many fields:

- Civilian heating fuel: it can be directly used as fuel for home fireplaces and heating stoves, especially widely used in Europe and the United States.

- Raw material for industrial production: it is suitable for industrial processing such as furniture manufacturing and woodworking products.

- Creative and handicrafts: part of the wood sticks can be used in handicrafts, creative production and other special areas.

- Agricultural use: the ashes after burning can be used as phosphorus fertilizer, promoting the reuse of resources.

- Convenient storage and transportation: the finished product has high density, small volume, and easy packaging (shrink-wrap packaging), which is convenient for storage and transportation, and reduces costs.

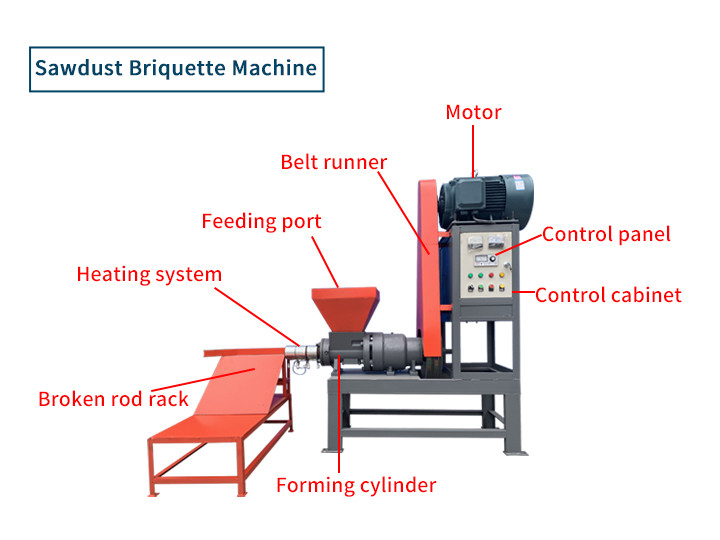

Structure of sawdust briquette making machine

This sawdust briquette machine is mainly composed of a motor, control cabinet & control panel, feed port, forming cylinder, heating system, etc.

- The motor uses a high-quality motor with a full copper core, and the mold is made of chromium-manganese alloy, which has good high-temperature and oxidation resistance.

- The hopper adopts a large opening design, which is convenient for feeding and makes the feeding more uniform.

- There are a variety of models of molds from the discharge port, and they can also be customized according to customer needs.

- The discharge port is equipped with a broken rod rack, which can control the length of the formed biomass charcoal between 10-15cm.

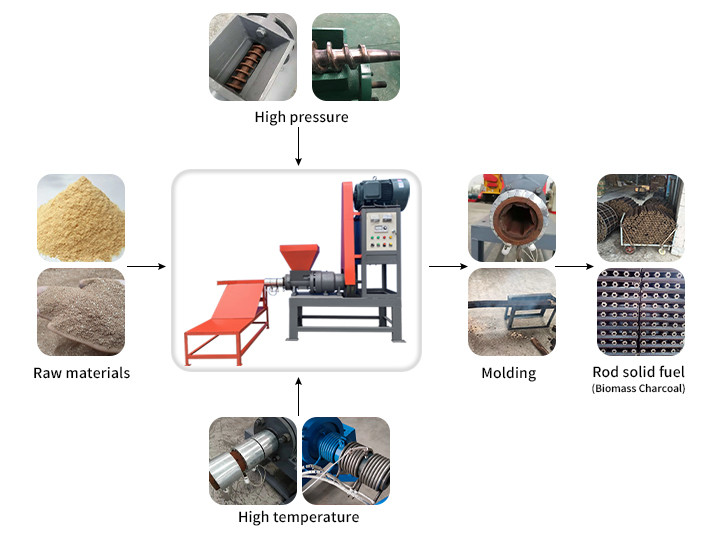

Wood sawdust briquette machine working principle

- Preheating the molding cylinder: turn on the heating ring to heat the temperature inside the molding cylinder to 280-300°C.

- Start the motor: start the motor of the equipment, ready to feed the material.

- Feed and extrusion molding: put the treated raw materials into the feeding port, and the screw propeller will extrude the materials forward.

- High-temperature and high-pressure molding: under the action of high temperature and screw extrusion pressure, the lignin in the material will soften and gelatinize, and then be extruded through the mold to make hollow bar-shaped fuel.

Tips for the use of sawdust briquette machine

Preparation for use

- Check the oil level of the machine before starting, it is recommended to fill about 750ml of lubricant.

- Before starting the machine, run it without load for 10 minutes to make sure there is no jamming or clogging. If there is any abnormality, stop the machine immediately for investigation.

Temperature setting

- Adjust the preset temperature according to the raw material: sawdust of mixed wood about 320°C, rice husk about 260°C.

- Other materials according to the hardness of the appropriate increase or decrease, each increase in hardness of about 10 ℃.

Adjustment of using process

- Performance of too high temperature (too fast stick out, black color): adjust the temperature downward gradually by 3°C each time, until the stick body is brown.

- Temperature is too low performance: (the speed of the bar is slow, the color is light): gradually adjust the temperature upward, each time to increase 5 ℃, until the bar is normal.

Shutdown operation

- Before stopping the machine, empty the residual material in the hopper and press the reverse button to withdraw the residual material from the propeller shaft.

- After shutting down the equipment, the heating ring will continue to work for 10 minutes to carbonize the residue in the molding cylinder, which is convenient for the next startup.

Display of biomass briquette making machine

Machine matching molding cylinder display

The important working parts of the pini kay briquette machine are the screw propeller, heating ring, and molding cylinder. Due to the high intensity of work, these parts wear out quickly.

These parts produced by Shuliy are of good quality, very durable, and have a long service life. If customers buy back these accessories, they can be sold at a discount, and they can be given free of charge if the purchase quantity is large.

Biomass sawdust briquette machine parameters

| Model | SL-15 | SL-18 | SL-22 |

| Capacity (kg/h) | 160-200 | 220-260 | 250-300 |

| Motor(kw) | 15 | 18 | 22 |

| Heating temperature(℃) | 260-380 | 260-380 | 260-380 |

| Dimension (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

Related video about sawdust briquette machine

If you have developed a strong interest in the performance and benefits of the wood sawdust briquette machine, we encourage you to contact our professional team immediately. We are ready to provide you with detailed information, answer your questions, and arrange for you to visit our factory to experience the efficient production and superior quality of our wood briquette machines.