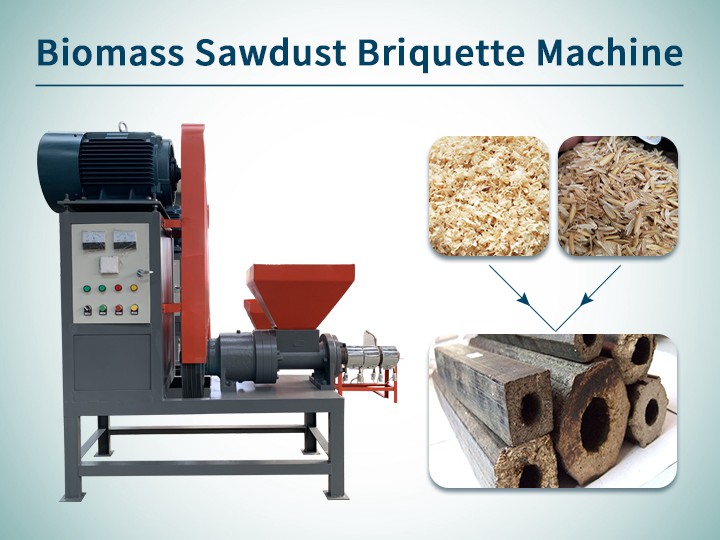

A máquina de briquete de serragem de biomassa adota tecnologia de moldagem sem aglutinante de alta temperatura e alta pressão. Ela pode prensar resíduos agrícolas e florestais, como serragem, aparas, casca de arroz, cascas de amendoim, bagaço, etc., em combustível de biomassa em forma de bastão oco com uma densidade de 1,0-1,4g/cm³.

Comparado com a madeira comum, o briquete de serragem é mais fácil de acender, o valor calórico é aumentado em mais de 20%, a poluição é menor e a densidade é maior. É fácil de armazenar, transportar e queimar por um longo período de tempo, proporcionando uma solução de energia limpa econômica e prática para resíduos agrícolas e florestais.

Matérias-primas e aplicações de briquetes de biomassa

A máquina de briquete de serragem de combustível de biomassa é adequada para muitos tipos de resíduos agrícolas e florestais que contêm lignina, principalmente incluindo:

- Cavacos de madeira, cavacos de bambu, aparas

- Casca de arroz, cascas de amendoim, espigas de milho

- Caule de algodão, caules de culturas, ramos de poda de pomares e jardins

- Bagaço, casca de coco, fábrica de móveis, fábrica de produtos de bambu, resíduos de borda de fábrica de palitinhos, etc.

Requisitos da matéria-prima: tamanho da partícula ≤ 5 mm; teor de umidade ≤ 12%. (O triturador de madeira e o secador rotativo de tambor para serragem podem ser usados para pré-tratamento)

Produto acabado do extrusor de briquetes de serragem

As hastes de combustível de biomassa feitas pela máquina de briquete de serragem são amplamente utilizadas em muitos campos:

- Combustível de aquecimento civil: pode ser usado diretamente como combustível para lareiras e fogões de aquecimento em casa, especialmente amplamente utilizado na Europa e nos Estados Unidos.

- Matéria-prima para produção industrial: é adequado para processamento industrial, como fabricação de móveis e produtos de marcenaria.

- Criatividade e artesanato: parte dos bastões de madeira pode ser usada em artesanato, produção criativa e outras áreas especiais.

- Uso agrícola: as cinzas após a queima podem ser usadas como fertilizante de fósforo, promovendo a reutilização de recursos.

- Armazenamento e transporte convenientes: o produto acabado tem alta densidade, pequeno volume e embalagem fácil (embalagem a vácuo), o que é conveniente para armazenamento e transporte, além de reduzir custos.

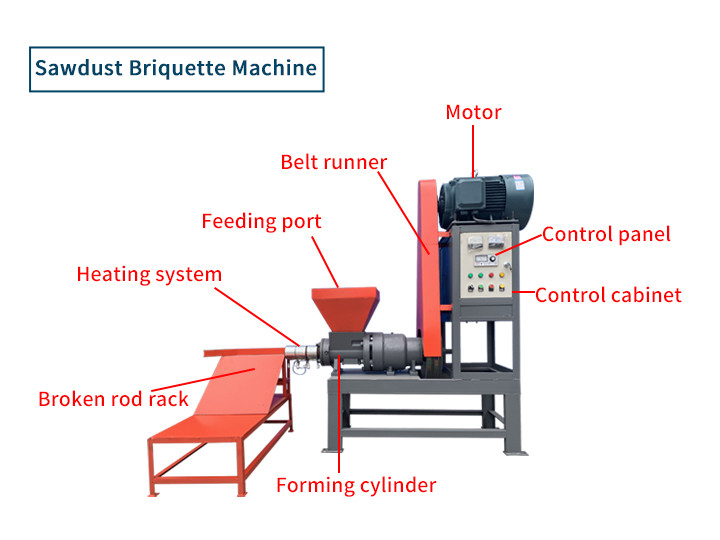

Estrutura da máquina de fazer briquetes de serragem

Esta máquina de briquete de serragem é composta principalmente por um motor, gabinete de controle e painel de controle, porta de alimentação, cilindro de moldagem, sistema de aquecimento, etc.

- O motor utiliza um motor de alta qualidade com núcleo de cobre completo, e o molde é feito de liga de cromo-manganês, que possui boa resistência a altas temperaturas e oxidação.

- O funil adota um design de grande abertura, o que é conveniente para a alimentação e torna a alimentação mais uniforme.

- Existem uma variedade de modelos de moldes na porta de descarga, e eles também podem ser personalizados de acordo com as necessidades do cliente.

- A porta de descarga é equipada com um suporte de haste quebrada, que pode controlar o comprimento do carvão de biomassa formado entre 10-15cm.

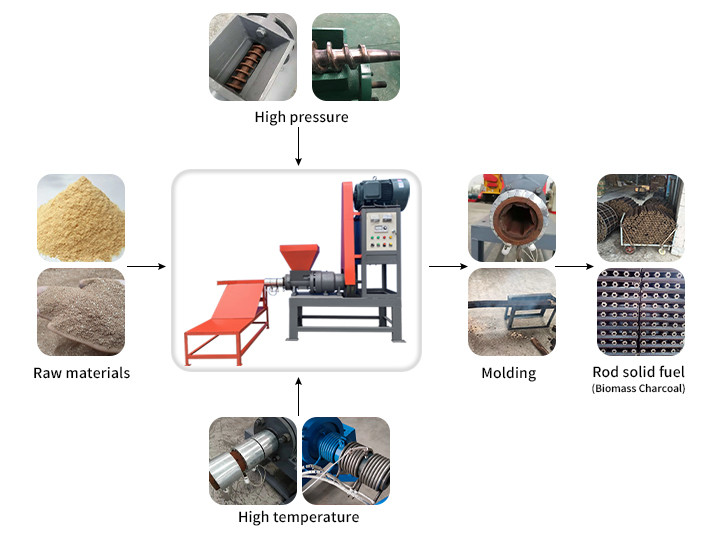

Princípio de funcionamento da máquina de briquete de serragem

- Pré-aquecendo o cilindro de moldagem: ligue o anel de aquecimento para aquecer a temperatura dentro do cilindro de moldagem para 280-300°C.

- Inicie o motor: ligue o motor do equipamento, pronto para alimentar o material.

- Alimentação e moldagem por extrusão: coloque as matérias-primas tratadas na porta de alimentação, e o parafuso propulsor extrudará os materiais para frente.

- Moldagem em alta temperatura e alta pressão: sob a ação de alta temperatura e pressão de extrusão do parafuso, a lignina no material amolecerá e gelatinizará, e então será extrudada através do molde para fazer combustível em forma de barra oca.

Dicas para o uso da máquina de briquete de serragem

Preparação para uso

- Verifique o nível de óleo da máquina antes de iniciar, recomenda-se encher cerca de 750ml de lubrificante.

- Antes de ligar a máquina, opere-a sem carga por 10 minutos para garantir que não haja obstruções ou entupimentos. Se houver alguma anormalidade, pare a máquina imediatamente para investigação.

Configuração de temperatura

- Ajuste a temperatura pré-definida de acordo com a matéria-prima: serragem de madeira mista cerca de 320°C, casca de arroz cerca de 260°C.

- Outros materiais devem ser ajustados de acordo com a dureza, aumentando ou diminuindo adequadamente, cada aumento na dureza é de cerca de 10 ℃.

Ajuste do processo de uso

- Desempenho de temperatura muito alta (sai muito rápido, cor preta): ajuste a temperatura para baixo gradualmente em 3°C a cada vez, até que o corpo do bastão fique marrom.

- A temperatura está muito baixa, desempenho: (a velocidade da barra está lenta, a cor está clara): ajuste gradualmente a temperatura para cima, aumentando 5 ℃ a cada vez, até que a barra esteja normal.

Operação de desligamento

- Antes de parar a máquina, esvazie o material residual no funil e pressione o botão de reverso para retirar o material residual do eixo do propulsor.

- Após desligar o equipamento, o anel de aquecimento continuará a funcionar por 10 minutos para carbonizar o resíduo no cilindro de moldagem, o que é conveniente para a próxima partida.

Exibição da máquina de fabricação de briquetes de biomassa

Exibição do cilindro de moldagem de correspondência de máquina

As partes importantes da máquina de briquete pini kay são o parafuso propulsor, o anel de aquecimento e o cilindro de moldagem. Devido à alta intensidade de trabalho, essas partes se desgastam rapidamente.

Estas peças produzidas pela Shuliy são de boa qualidade, muito duráveis e têm uma longa vida útil. Se os clientes comprarem de volta esses acessórios, eles podem ser vendidos com desconto, e podem ser dados gratuitamente se a quantidade comprada for grande.

Parâmetros da máquina de briquete de serragem de biomassa

| Modelo | SL-15 | SL-18 | SL-22 |

| Capacidade (kg/h) | 160-200 | 220-260 | 250-300 |

| Motor (kw) | 15 | 18 | 22 |

| Temperatura de aquecimento (℃) | 260-380 | 260-380 | 260-380 |

| Dimensão (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

Vídeo relacionado sobre a máquina de briquete de serragem

Se você desenvolveu um forte interesse no desempenho e nos benefícios da máquina de briquetagem de serragem de madeira, encorajamos você a entrar em contato com nossa equipe profissional imediatamente. Estamos prontos para fornecer informações detalhadas, responder às suas perguntas e providenciar uma visita à nossa fábrica para você experimentar a produção eficiente e a qualidade superior de nossas máquinas de briquetagem de madeira.