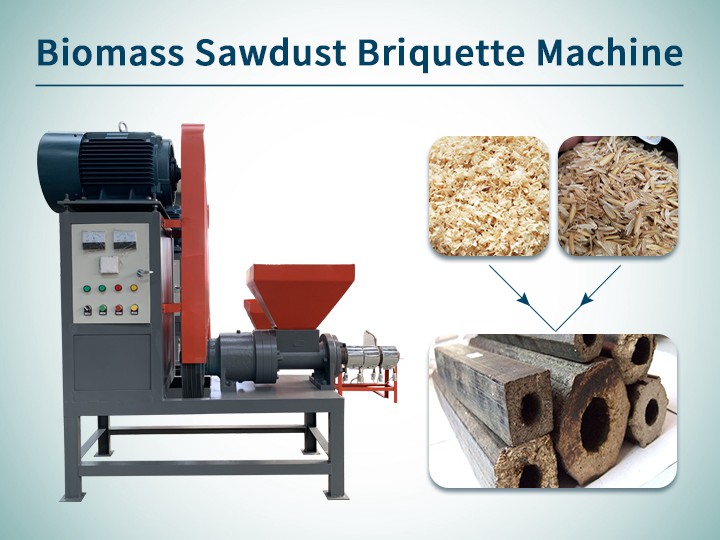

Mashine ya briquette ya sawdust ya biomass inatumia teknolojia ya kutengeneza bila binder kwa joto na shinikizo kubwa. Inaweza kubana taka za kilimo na misitu kama vile sawdust, shavings, maganda ya mpunga, maganda ya karanga, bagasse, n.k., kuwa mafuta ya biomass ya gogo tupu yenye wiani wa 1.0-1.4g/cm³.

Ikilinganishwa na kuni za kawaida, briquette ya sawdust ni rahisi kuwaka, thamani ya joto imeongezeka kwa zaidi ya 20%, uchafuzi ni wa chini, na wiani ni wa juu. Ni rahisi kuhifadhi, kusafirisha, na kuchoma kwa muda mrefu, ikitoa suluhisho la nishati safi la kiuchumi na pratikali kwa taka za kilimo na misitu.

Råmaterial och tillämpningar av biomassabriketter

Maskinen för sågspånbriketter av biomassabränsle är lämplig för många typer av jordbruks- och skogsavfall som innehåller lignin, huvudsakligen inklusive:

- Träflis, bambuflis, spån

- Ris skal, jordnötsskal, majskolvar

- Bomullsstockar, grödstockar, grenar från fruktträd och trädgårdar

- Bagasse, kokosnötskal, möbelfabrik, bambuproduktfabrik, avfall från ätpinnar, etc.

Mahitaji ya malighafi: saizi ya chembe ≤ 5 mm; unyevu ≤ 12%. (Kiunzi cha mbao na kikaushio cha mbao kinachozunguka cha ngoma vinaweza kutumika kwa ajili ya matibabu ya awali)

Bidhaa iliyokamilishwa ya extruder ya briquette za sawdust

Biomassabränslerodarna som tillverkas av maskinen för sågspånbriketter används i stor utsträckning inom många områden:

- Benzini ya joto la kiraia: inaweza kutumika moja kwa moja kama mafuta kwa ajili ya mifereji ya nyumbani na jiko la kupashia joto, hasa inatumika sana barani Ulaya na Marekani.

- Malighafi kwa ajili ya uzalishaji wa viwandani: inafaa kwa usindikaji wa viwandani kama vile utengenezaji wa samani na bidhaa za useremala.

- Ubunifu na kazi za mikono: sehemu ya vijiti vya mbao vinaweza kutumika katika kazi za mikono, uzalishaji wa ubunifu na maeneo mengine maalum.

- Matumizi ya kilimo: majivu baada ya kuchoma yanaweza kutumika kama mbolea ya fosforasi, ikichochea matumizi ya rasilimali tena.

- Hifadhi na usafirishaji rahisi: bidhaa iliyokamilishwa ina wiani mkubwa, saizi ndogo, na ufungaji rahisi (ufungaji wa kufifisha), ambayo ni rahisi kwa hifadhi na usafirishaji, na inapunguza gharama.

Struktur av maskin för tillverkning av sågspånbriketter

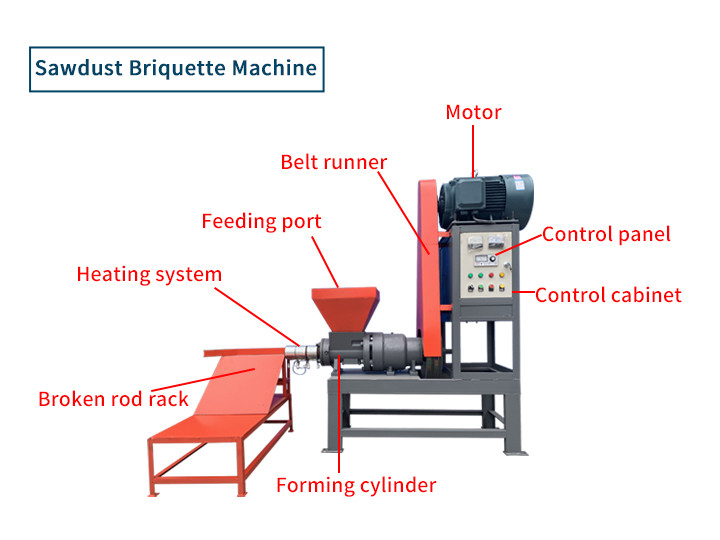

Mashine hii ya briketi za sawdust ina sehemu kuu kama vile motor, kabati la kudhibiti & paneli ya kudhibiti, bandari ya kulisha, silinda ya umbo, mfumo wa kupasha joto, n.k.

- Motorin använder en högkvalitativ motor med en hel kopparkärna, och formen är gjord av krom-manganlegering, som har bra högtemperatur- och oxidationsbeständighet.

- Hopper ina muundo wa ufunguzi mkubwa, ambao ni rahisi kwa kulisha na kufanya kulisha kuwa sawa zaidi.

- Kuna aina mbalimbali za mifano ya molds kutoka bandari ya kutolea, na zinaweza pia kubinafsishwa kulingana na mahitaji ya wateja.

- Bandari ya kutolea imewekwa na rack ya fimbo iliyovunjika, ambayo inaweza kudhibiti urefu wa makaa ya biomass yaliyoundwa kati ya 10-15cm.

Arbetsprincip för maskin för sågspånbriketter

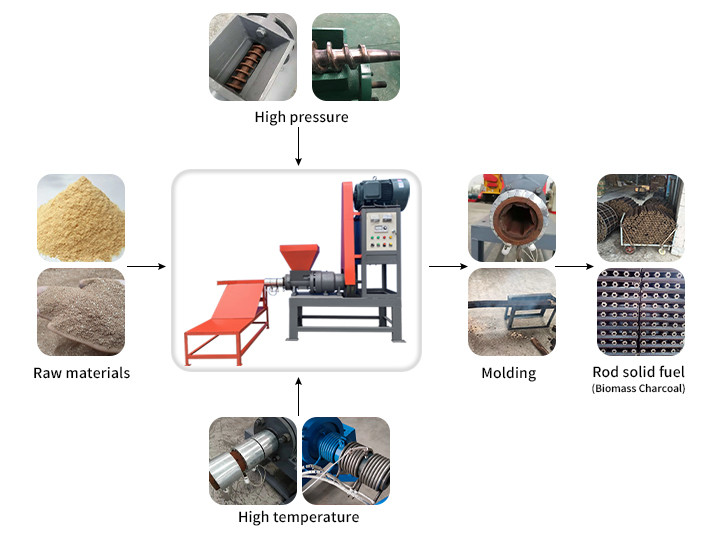

- Kuweka joto silinda ya umbo: washitiri joto ili kupasha joto ndani ya silinda ya umbo hadi 280-300°C.

- Anza motor: anza motor ya vifaa, tayari kulisha nyenzo.

- Kulisha na kuunda kwa extrusion: weka malighafi zilizotibiwa kwenye bandari ya kulisha, na propela ya screw itatoa malighafi mbele.

- Moldning vid hög temperatur och högtryck: under påverkan av hög temperatur och skruvextruderingstryck kommer ligninet i materialet att mjukna och gelatisera, och sedan extruderas genom formen för att skapa ihåliga stavformade bränslen.

Tips för användning av sågspån brikettmaskin

Maandalizi ya matumizi

- Angalia kiwango cha mafuta cha mashine kabla ya kuanza, inapendekezwa kujaza takriban 750ml ya lubricant.

- Innan du startar maskinen, kör den utan last i 10 minuter för att säkerställa att det inte finns någon blockering eller igensättning. Om det finns någon avvikelse, stoppa maskinen omedelbart för undersökning.

Kuweka halijoto

- Panga joto lililowekwa kulingana na malighafi: sawdust ya mti mchanganyiko karibu 320°C, makapi ya mchele karibu 260°C.

- Malighafi nyingine kulingana na ugumu wa kuongezeka au kupungua, kila ongezeko la ugumu ni takriban 10 ℃.

Kurekebisha mchakato wa matumizi

- Utendaji wa joto la juu sana (kutoa haraka, rangi ya giza): punguza joto hatua kwa hatua kwa 3°C kila wakati, hadi mwili wa fimbo uwe rangi ya kahawia.

- Joto ni baridi sana utendaji: (mwendo wa bar ni polepole, rangi ni nyepesi): ongeza joto taratibu, kila wakati ongeza 5 ℃, hadi bar iwe ya kawaida.

Operesheni ya kuzima

- Innan du stänger av maskinen, töm det återstående materialet i tråget och tryck på bakåtknappen för att dra tillbaka det återstående materialet från propelleraxeln.

- Baada ya kuzima vifaa, pete ya kupasha joto itaendelea kufanya kazi kwa dakika 10 ili kukarboni mabaki katika silinda ya umbo, ambayo ni rahisi kwa kuanzisha tena.

Onyesho la mashine ya kutengeneza briquette za biomass

Onyesho la silinda ya umbo wa mashine inayolingana

Se muhimu sehemu za kazi za mashine ya pini kay briquette ni propela ya screw, pete ya kupasha joto, na silinda ya umbo. Kutokana na nguvu kubwa ya kazi, sehemu hizi huvaa haraka.

Se sehemu hizi zinazozalishwa na Shuliy zina ubora mzuri, ni za kudumu sana, na zina muda mrefu wa huduma. Ikiwa wateja watanunua vifaa hivi, vinaweza kuuzwa kwa punguzo, na vinaweza kutolewa bure ikiwa kiasi cha ununuzi ni kikubwa.

Parametrar för biomassa sågspånbrikettmaskin

| Modell | SL-15 | SL-18 | SL-22 |

| Kapasitet (kg/h) | 160-200 | 220-260 | 250-300 |

| Motor (kw) | 15 | 18 | 22 |

| Temperatur för uppvärmning (℃) | 260-380 | 260-380 | 260-380 |

| Miwango (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

Video inayohusiana kuhusu mashine ya briquette za sawdust

Ikiwa umeendeleza nia kubwa katika utendaji na manufaa ya mashine ya briketi ya mbao ya mbao, tunakuhimiza kuwasiliana na timu yetu ya kitaalamu mara moja. Tuko tayari kukupa taarifa za kina, kujibu maswali yako, na kupanga wewe kutembelea kiwanda chetu ili kupata uzoefu wa uzalishaji wenye ufanisi na ubora bora wa mashine zetu za briketi za mbao.