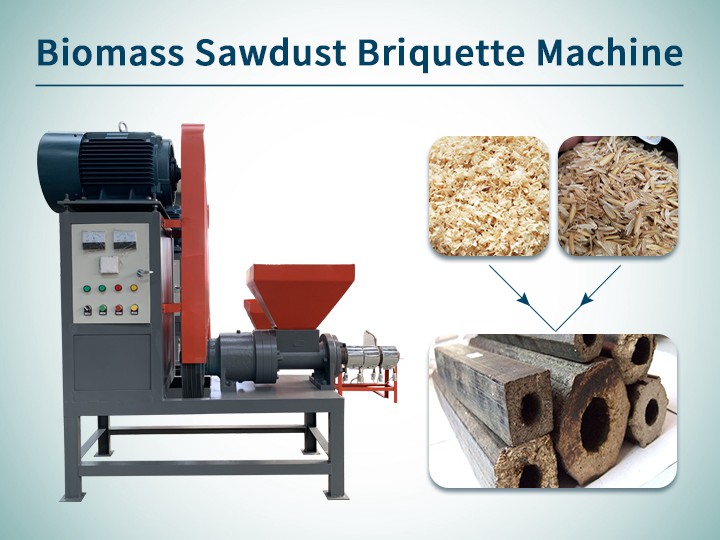

바이오매스 톱밥 브리켓 기계는 고온 및 고압의 결합제 없는 성형 기술을 채택합니다. 이 기계는 톱밥, 나무 조각, 쌀겨, 땅콩 껍질, 바가스 등과 같은 농업 및 임업 폐기물을 압축하여 밀도 1.0-1.4g/cm³의 중공 스틱 바이오매스 연료로 만들 수 있습니다.

일반 목재와 비교할 때, 톱밥 브리켓은 점화가 더 쉽고, 열량이 20% 이상 증가하며, 오염이 낮고 밀도가 높습니다. 저장, 운반 및 장시간 연소가 용이하여 농업 및 임업 폐기물에 대한 경제적이고 실용적인 청정 에너지 솔루션을 제공합니다.

바이오매스 브리켓의 원자재 및 응용

바이오매스 연료 톱밥 브리켓 기계는 리그닌을 포함한 다양한 농업 및 임업 폐기물에 적합합니다. 주로 포함되는 것은:

- 목재 칩, 대나무 칩, 깎은 조각

- 쌀겨, 땅콩 껍질, 옥수수 이삭

- 면화 줄기, 농작물 줄기, 과수원 및 정원 가지치기 가지

- 바가스, 코코넛 껍질, 가구 공장, 대나무 제품 공장, 젓가락 공장 가장자리 폐기물 등.

원료 요구사항: 입자 크기 ≤ 5mm; 수분 함량 ≤ 12%. (우드 칩 분쇄기 및 드럼 회전식 톱밥 건조기를 전처리용으로 사용할 수 있습니다)

목재 톱밥 브리켓 압출기 완제품

톱밥 브리켓 기계로 만든 바이오매스 연료 막대는 여러 분야에서 널리 사용됩니다:

- 민간 난방 연료: 주로 유럽과 미국에서 널리 사용되는 가정용 벽난로와 난방 스토브의 연료로 직접 사용될 수 있습니다.

- 산업 생산을 위한 원료: 가구 제조 및 목공 제품과 같은 산업 가공에 적합합니다.

- 창작 및 수공예: 나무 막대의 일부는 수공예, 창의적인 제작 및 기타 특별한 분야에 사용될 수 있습니다.

- 농업용: 연소 후의 재는 인산 비료로 사용될 수 있어 자원의 재사용을 촉진합니다.

- 편리한 저장 및 운송: 완제품은 밀도가 높고 부피가 작으며 포장이 용이(수축 포장)하여 저장 및 운송이 편리하고 비용을 절감합니다.

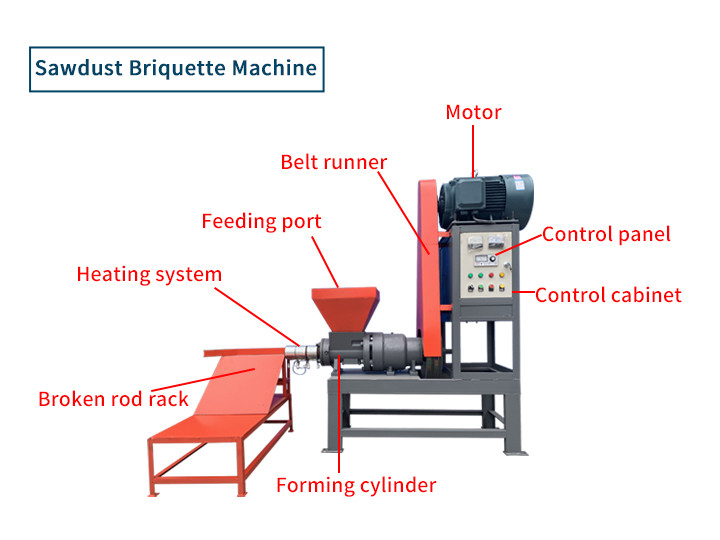

톱밥 브리켓 제작 기계의 구조

이 톱밥 브리켓 기계는 주로 모터, 제어 캐비닛 및 제어 패널, 급료 포트, 성형 실린더, 난방 시스템 등으로 구성됩니다.

- 모터는 전체 구리 코어가 있는 고품질 모터를 사용하며, 금형은 크롬-망간 합금으로 만들어져 있어 고온 및 산화 저항성이 우수합니다.

- 호퍼는 큰 개구부 디자인을 채택하여 급료가 용이하고 더 고르게 급료할 수 있도록 합니다.

- 배출 포트에서 다양한 모델의 금형이 있으며, 고객의 요구에 따라 맞춤 제작할 수도 있습니다.

- 배출 포트에는 파손 막대 선반이 장착되어 있어 형성된 바이오매스 숯의 길이를 10-15cm 사이로 조절할 수 있습니다.

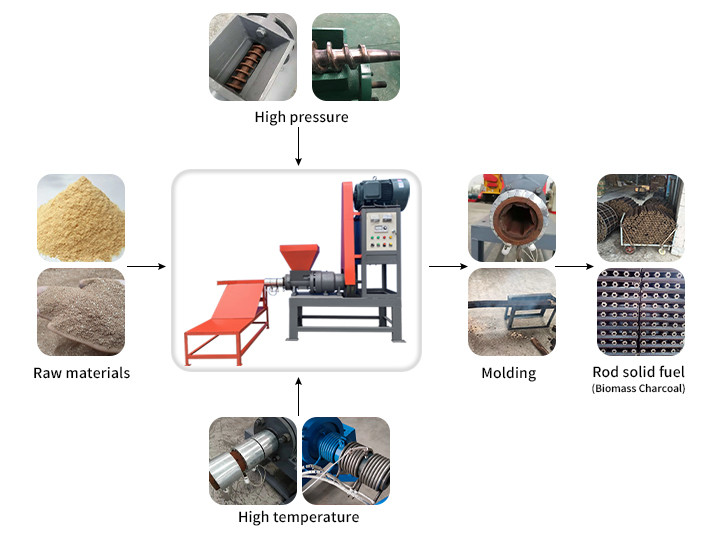

우드 톱밥 브리켓 기계 작동 원리

- 성형 실린더 예열: 성형 실린더 내부의 온도를 280-300°C로 가열하기 위해 히팅 링을 켭니다.

- 모터 시작: 장비의 모터를 시작하여 재료를 공급할 준비를 합니다.

- 급여 및 압출 성형: 처리된 원료를 급여 포트에 넣으면 나사 프로펠러가 원료를 앞으로 압출합니다.

- 고온 고압 성형: 고온과 나사 압출 압력의 작용하에 재료의 리그닌이 부드러워지고 젤라틴화되며, 이후 금형을 통해 압출되어 중공 막대 모양의 연료가 만들어집니다.

톱밥 브리켓 기계 사용을 위한 팁

사용 준비

- 시작하기 전에 기계의 오일 수준을 확인하십시오. 약 750ml의 윤활유를 채우는 것이 좋습니다.

- 기계를 시작하기 전에 10분 동안 무부하로 작동시켜서 걸림이나 막힘이 없는지 확인하십시오. 이상이 있을 경우 즉시 기계를 멈추고 조사하십시오.

온도 설정

- 원료에 따라 설정된 온도를 조정하십시오: 혼합 목재의 톱밥은 약 320°C, 쌀 껍질은 약 260°C입니다.

- 다른 원료는 경도에 따라 적절히 증가 또는 감소시키며, 경도가 약 10℃ 증가할 때마다 조정합니다.

사용 공정 조정

- 온도가 너무 높을 경우(너무 빠르게 튀어나오고 검은색): 스틱 본체가 갈색이 될 때까지 매번 3°C씩 온도를 점진적으로 낮추십시오.

- 온도가 너무 낮습니다 성능: (바의 속도가 느리고 색상이 밝습니다): 온도를 점차적으로 위로 조정하고, 매번 5℃씩 증가시켜 바가 정상 상태가 될 때까지 조정합니다.

작동 중지

- 기계를 멈추기 전에 호퍼에 남아 있는 잔여 물질을 비우고 역전 버튼을 눌러 프로펠러 샤프트에서 잔여 물질을 빼내십시오.

- 장비를 종료한 후, 가열 링은 성형 실린더의 잔여물을 탄화시키기 위해 10분 동안 계속 작동하며, 이는 다음 시작 시 편리합니다.

바이오매스 브리켓 제조 기계 전시

기계 맞춤 성형 실린더 전시

피니 카이 브리켓 기계의 중요한 작동 부품은 나사 프로펠러, 히팅 링 및 성형 실린더입니다. 작업 강도가 높기 때문에 이러한 부품은 빠르게 마모됩니다.

Shuliy에서 생산한 이 부품들은 품질이 좋고 매우 내구성이 뛰어나며 긴 서비스 수명을 가지고 있습니다. 고객이 이러한 액세서리를 재구매하면 할인된 가격으로 판매할 수 있으며, 구매 수량이 많으면 무료로 제공할 수 있습니다.

바이오매스 톱밥 브리켓 기계 매개변수

| 모델 | SL-15 | SL-18 | SL-22 |

| 용량 (kg/h) | 160-200 | 220-260 | 250-300 |

| 모터(kw) | 15 | 18 | 22 |

| 가열 온도(℃) | 260-380 | 260-380 | 260-380 |

| 치수 (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

톱밥 브리켓 기계에 대한 관련 비디오

나무 톱밥 브리켓 기계의 성능과 이점에 대해 강한 관심을 가지셨다면, 지금 바로 저희 전문 팀에 연락해 주시기 바랍니다. 저희는 상세한 정보를 제공하고, 질문에 답변하며, 저희 공장을 방문하여 저희 나무 브리켓 기계의 효율적인 생산과 우수한 품질을 직접 경험하실 수 있도록 준비되어 있습니다.