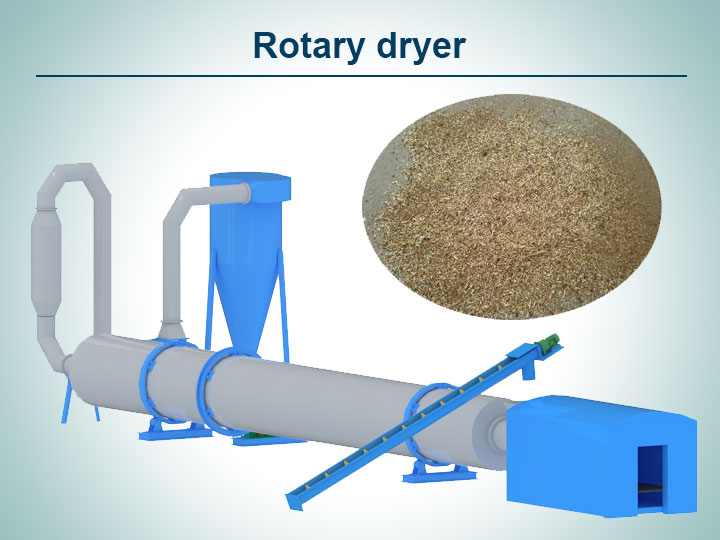

The drum sawdust rotary dryer is a kind of high-efficiency and energy-saving industrial drying equipment, which is commonly used in charcoal machine production lines and all kinds of wet material treatment processes.

The equipment is fully contacted with the material by hot air in the drum, and is also equipped with multiple sets of stirring shafts and scrapers. This makes it possible to push the material forward in the drying process, so that it can be rapidly dehydrated and evenly dried.

The rotary dryer is reasonable in structure, high in automation, and easy to operate. Widely used in wood processing, biomass fuel, mining, building materials, chemical industry, and other industries, it is currently one of the most commonly used industrial drying equipment.

Applications of industrial rotary dryers

The applicable raw materials and industries of the drum dryer are very wide, specifically including:

- Wood raw materials: sawdust, wood chips, tree branches, rice husk, straw, bagasse and other biomass particulate materials.

- Agricultural raw materials: pasture, grain, feed and other agricultural by-products.

- Mineral and building materials industry: river sand, slag, limestone, clay, water slag and so on.

- Other industries: widely used in metallurgy, coal, chemical industry, cement, pharmaceuticals and other fields of wet material drying treatment.

Working principle of drum rotary dryer

- Material entering the machine: wet material is fed into the machine through a conveyor belt and enters the rotating drum through a pipe.

- Hot air heating: on one side, the material enters, and on the other side, there is hot air coming in. The hot air and the material are in full contact inside the drum, which helps the material to dry quickly.

- Cylinder rotation to push the material forward: the drum is installed at an incline, and the material will move forward slowly when it is rotating. There are a lot of lifting boards on the cylinder wall, which will constantly throw up and turn the material to make it contact with the hot air more fully.

- Drying while moving: in the process of moving, the hot air is continuously heated, and the moisture in the material is slowly evaporated.

- Discharge dry material and exhaust gas: the dried material is discharged from the outlet and sent to the next stage. Exhaust gases and steam generated are discharged from the upper exhaust port, and the excess dust will be recovered by the collector.

Drum dryer machine main advantages

- High-efficiency drying: adopting high-temperature rapid drying technology with high thermal efficiency and heat transfer intensity, which can significantly improve the output.

- Simple operation: highly automated, support temperature and speed adjustment, no need for complex manual operation, stable and reliable.

- Uniform drying: direct contact between material and hot air, full drying process, good moisture consistency of material.

- Flexible production capacity: the output is adjustable from 10 tons to 100 tons per hour to meet different customer needs.

- Strong expandability: the structural design takes into account the redundancy of production capacity, and there is no need to replace the equipment for later expansion.

- Environmental protection and energy saving: heat energy can be recycled, reducing energy consumption, saving operating costs, in line with environmental requirements.

- Wide application: it can be used for drying all kinds of granular, flake and powder materials, with strong adaptability.

- Long service life: the equipment is made of high-quality steel, anti-wear and high temperature resistance, low maintenance costs.

Display of wood sawdust rotary dryer

Sawdust dryer applied in charcoal production line

- In the charcoal molding production line, the dryer is essential to process the raw materials to the right humidity. Only after drying, the raw materials be processed in the next step.

- Firstly, we need to crush the raw materials into suitable size, and then put these materials into the drum rotary dryer.

- After drying, the materials are fed into the wood sawdust briquette press machine for extrusion molding. After extrusion molding, it is sent to the carbonization furnace for carbonization to make charcoal sticks.

Rorary drum drying machine parameters

| Model(mm) | Rotate Speed(r/min) | Initial Temperature | Power(kw) | Capacity(t/h) | Weight(t) |

| SL600*6000 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| SL800*8000 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| SL800*10000 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| SL1000*10000 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| SL1200*12000 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| SL1200*12000 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| SL1500*12000 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| SL1800*12000 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| SL2200*12000 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| SL2200*18000 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| SL2200*20000 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| SL2400*20000 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| SL3000*20000 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| SL3000*25000 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Thank you for reading our introduction about the sawdust rotary dryer. If you are interested in this efficient and reliable equipment and would like to know more detailed information, please feel free to contact us. We are eager to provide you with customized solutions to meet your production needs. Meanwhile, you are welcome to visit our factory to experience and understand our advanced technology and equipment. We look forward to working with you!