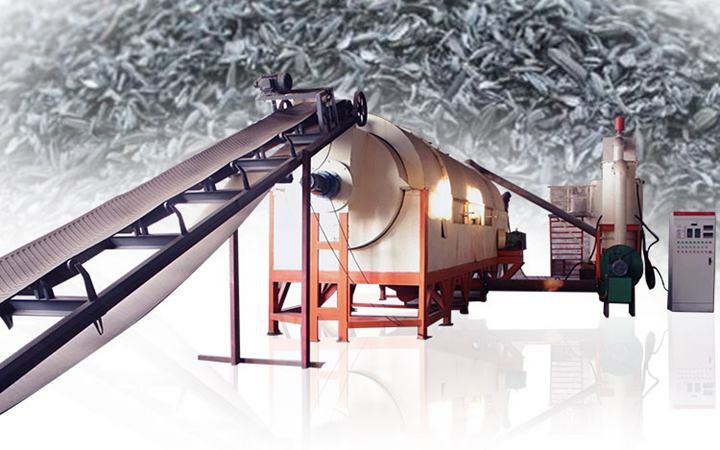

Smokeless carbonization furnace is the latest research and development of matching equipment for charcoal machine. It can produce smokeless and dust-free, and can be used for dryer and other equipment after recovery of flue gas.

Working principle of smokeless charring furnace

The smokeless carbonization furnace takes the self produced gas stove as the heat source, and uses the methane gas to pass through.

The outlet temperature of the burner can reach 800 1200, and the flow rate can reach 3 5 meters per second. The high-temperature air flow generated by the burner is heated outside the combustion chamber. It should be noted that when heating, the furnace temperature is 100 150, the maximum moisture content in the furnace is 4 8% water per kilogram of raw material rod, and 1 700 kg of raw material is brought into the furnace. More than 100 kilograms of water can be brought in. This water is the enemy of carbonization. Because the raw material rod of machine-made carbon is most afraid of dampness, which means that it will be crushed into powder, seriously affecting the quality of carbonization. Therefore, the moisture drainage system is essential. The time of moisture drainage is 1-1.5 hours. When the temperature of the furnace in the carbonization room rises to 300 degrees Celsius, a large number of combustible materials will be produced in the furnace. Gases, each kilogram of raw material, can theoretically produce three cubic methane gases that can be heated by carbonization. Drying heat source use, furnace temperature can be adjusted at will, low-temperature carbon in general at 400 (8 hours to complete), high-temperature carbon at 600 (10 hours to complete).

Characteristics of smokeless charring furnace

The carbonization time is short.

Smoke-free, environment-friendly products;

The smokeless carbonization furnace is simple in operation and can be seen at a glance.

The product quality is guaranteed, the carbonization rate is 100%, the carbide is not crushed, the appearance is good, this product is a patent product.