The drum wood chipper can cut logs, branches, boards, bamboo, cotton stalks, and other wood or non-wood fiber raw materials into uniform specification slices (20-40mm in length, 3-5mm in thickness), with a qualification rate of over 97%. It is widely used in paper mills, particle board factories, medium and high-density fiberboard factories, biomass power plants, wood chip export bases, and so on.

Advantages of wood chips making machine

- Strong adaptability: it can be installed and used in different geographic environments and climatic conditions without being affected by seasons.

- No foundation installation: the equipment can be put into use within 1-2 days after arrival, saving 10-15 days.

- Cost saving: no foundation construction can save users about $500-2000 in labor and material expenses (depending on the model).

- Flexible and convenient installation: no need to fix the installation site, simple debugging, improve the flexibility and mobility of the equipment.

- Adjustable discharging direction: equipped with a second discharging device, the discharging direction can be adjusted flexibly according to the needs.

- Large output: daily processing capacity of 30-300 tons, to adapt to the production needs of different users.

- Easy operation: reasonable structure design, easy operation and maintenance, suitable for all kinds of users.

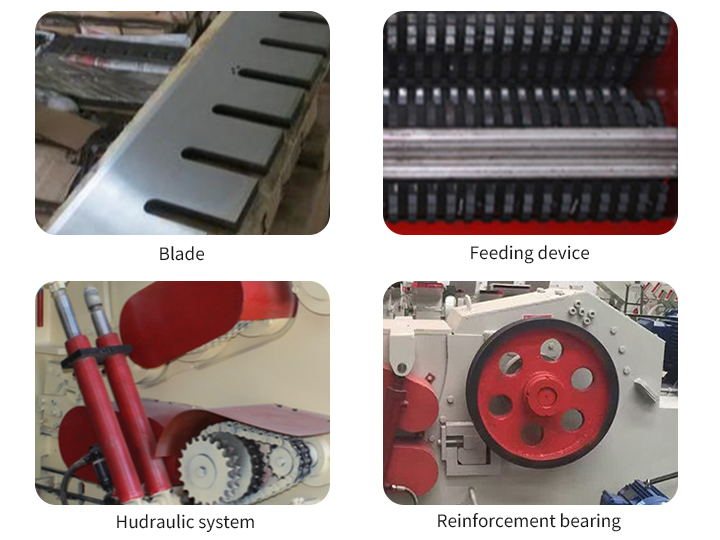

Wood chipping machine main structure

The drum wood chipper consists of high high-strength steel plate welded main machine, cutting tool system, upper and lower feed rollers, conveyor belt, inlet and outlet, motor, and hydraulic system.

With sturdy structure, smooth operation and synergistic cooperation of all parts, it can efficiently complete the wood chipping operation and is suitable for a variety of working conditions.

Working principle of drum wood chipper

The drum wood chipper realizes the transformation from raw material to refined wood chips in three stages, with high efficiency and controlled energy consumption:

Hydraulic feed pressurization

- The raw material is fed through a wide conveyor belt, and the double-roller hydraulic system automatically compacts and advances the material at a uniform speed.

- Overcoming the resistance to deformation of the branches ensures the stability of the continuous feeding.

- Intelligent adjustable roller pressure gap, suitable for all kinds of raw materials with diameter ≤ 350mm.

Multi-blade dynamic cutting

- The core knife drum integrates high-strength alloy flying knife set, rotating at a high speed of 960 rpm.

- The blade adopts radial spiral layout, which adheres to the raw material surface during the whole cutting process.

- Low resistance layered slicing is achieved, significantly reducing chip rates and extending tool life.

Cyclone sorting output

- The cut wood chips penetrate through the holes of the knife drum screen and are transported directionally by the high-speed negative pressure airflow generated by the knife impeller.

- The built-in grading screen automatically separates the oversized chips, and the qualified chips are cleanly output through the closed air duct.

- The impurities are returned to the crushing area for secondary processing to ensure that the finished piece diameter is accurate and up to standard (±1mm error).

Wood chippers can be further crushed into wood chips by adding a wood hammer mill crusher at the back end of the machine, and then used for charcoal making and other operations.

Finished product you can get

The finished product produced by this drum wood chipper has uniform particle size, fine texture, and smooth surface, which can be widely used in woodworking, paper making, and other fields.

Drum wood chipper parameters

| Model | SL215 | SL216 | SL218 | SL2113 |

| Raw material size(mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Knife number (piece) | 2 | 2 | 2 | 2 |

| Knife rotating speed(rpm) | 592 | 590 | 650 | 500 |

| Raw material diameter(mm) | 160 | 230 | 300 | 450 |

| Wood chip size(mm) | 30 | 30 | 30 | 38 |

| Capacity(t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Main motor power(kw) | 45 | 55 | 110 | 200-250 |

| Feed roller motor power(kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Oil pump motor power(kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Machine weight(kg) | 3590 | 5030 | 7000 | 11840 |

| Machine size(mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Conveyor motor power(kw) | 3 | 3 | 3 | 3 |

Thank you for reading about wood chipper. If you are interested in our machines or have any questions, please feel free to contact us. You can tell us specific requirements before ordering a wood chipper shredder. To protect the interests of our customers, we will select the most suitable machine for you. All customers interested in our machines are also welcome to visit our factory. We look forward to establishing a cooperative relationship with you.