Le déchiqueteur à tambour peut couper des bûches, des branches, des planches, du bambou, des tiges de coton et d'autres matières premières en fibres de bois ou non en tranches de spécifications uniformes (20-40 mm de longueur, 3-5 mm d'épaisseur), avec un taux de qualification de plus de 97 %. Il est largement utilisé dans les usines de papier, les usines de panneaux de particules, les usines de panneaux de fibres à moyenne et haute densité, les centrales électriques à biomasse, les bases d'exportation de copeaux de bois, etc.

Avantages de la machine à fabriquer des copeaux de bois

- Grande adaptabilité : elle peut être installée et utilisée dans différents environnements géographiques et conditions climatiques sans être affectée par les saisons.

- Pas d'installation de fondation : l'équipement peut être mis en service dans les 1 à 2 jours suivant son arrivée, économisant ainsi 10 à 15 jours.

- Économie de coûts : l'absence de construction de fondation peut faire économiser aux utilisateurs environ 500 à 2000 $ en frais de main-d'œuvre et de matériaux (selon le modèle).

- Installation flexible et pratique : pas besoin de fixer le site d'installation, simple à régler, améliore la flexibilité et la mobilité de l'équipement.

- Direction de décharge réglable : équipé d'un deuxième dispositif de décharge, la direction de décharge peut être ajustée de manière flexible en fonction des besoins.

- Grande production : capacité de traitement quotidienne de 30 à 300 tonnes, pour s'adapter aux besoins de production de différents utilisateurs.

- Facilité d'utilisation : conception de structure raisonnable, fonctionnement et maintenance faciles, adaptés à tous les types d'utilisateurs.

Structure principale de la machine à déchiqueter le bois

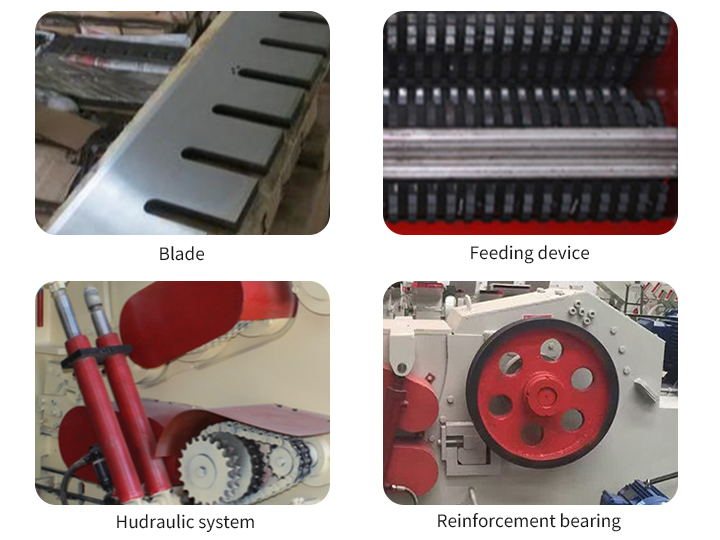

Le déchiqueteur à tambour est composé d'une machine principale en acier à haute résistance soudée, d'un système d'outils de coupe, de rouleaux d'alimentation supérieurs et inférieurs, d'un convoyeur, d'une entrée et d'une sortie, d'un moteur et d'un système hydraulique.

Avec une structure robuste, un fonctionnement fluide et une coopération synergique de toutes les pièces, il peut effectuer efficacement l'opération de déchiquetage du bois et est adapté à une variété de conditions de travail.

Principe de fonctionnement du déchiqueteur à bois à tambour

Le déchiqueteur à bois à tambour réalise la transformation de la matière première en copeaux de bois raffinés en trois étapes, avec une grande efficacité et une consommation d'énergie contrôlée :

Alimentation hydraulique sous pression

- La matière première est alimentée sur un large tapis roulant, et le système hydraulique à double rouleau compacte et avance automatiquement le matériau à une vitesse uniforme.

- Surmonter la résistance à la déformation des branches garantit la stabilité de l'alimentation continue.

- Écart de pression de rouleau ajustable intelligent, adapté à tous les types de matières premières avec un diamètre ≤ 350 mm.

Coupe dynamique multi-lames

- Le tambour de couteau central intègre un ensemble de couteaux volants en alliage haute résistance, tournant à une vitesse élevée de 960 tr/min.

- La lame adopte une disposition en spirale radiale, qui adhère à la surface de la matière première pendant tout le processus de coupe.

- Un tranchage en couches à faible résistance est réalisé, réduisant significativement les taux de copeaux et prolongeant la durée de vie de l'outil.

Sortie de tri par cyclone

- Les copeaux de bois coupés pénètrent à travers les trous de l'écran du tambour à couteaux et sont transportés de manière directionnelle par le flux d'air à haute vitesse et à pression négative généré par l'impulseur à couteaux.

- Le tamis de classement intégré sépare automatiquement les copeaux surdimensionnés, et les copeaux qualifiés sont évacués proprement par le conduit d'air fermé.

- Les impuretés sont renvoyées dans la zone de concassage pour un traitement secondaire afin de garantir que le diamètre de la pièce finie est précis et conforme aux normes (erreur de ±1 mm).

Les déchiqueteuses de bois peuvent être davantage broyées en copeaux de bois en ajoutant un broyeur à marteaux pour bois à l'arrière de la machine, puis utilisés pour la fabrication de charbon et d'autres opérations.

Produit fini que vous pouvez obtenir

Le produit fini produit par ce déchiqueteur à tambour a une taille de particule uniforme, une texture fine et une surface lisse, ce qui peut être largement utilisé dans le travail du bois, la fabrication de papier et d'autres domaines.

Paramètres de déchiqueteuse à bois à tambour

| Modèle | SL215 | SL216 | SL218 | SL2113 |

| Taille de la matière première (mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Numéro de couteau (pièce) | 2 | 2 | 2 | 2 |

| Vitesse de rotation du couteau (tr/min) | 592 | 590 | 650 | 500 |

| Diamètre de la matière première (mm) | 160 | 230 | 300 | 450 |

| Taille des copeaux de bois (mm) | 30 | 30 | 30 | 38 |

| Capacité (t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Puissance du moteur principal (kw) | 45 | 55 | 110 | 200-250 |

| Puissance du moteur du rouleau d'alimentation (kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Puissance du moteur de la pompe à huile (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Poids de la machine (kg) | 3590 | 5030 | 7000 | 11840 |

| Taille de la machine (mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Puissance du moteur du convoyeur (kw) | 3 | 3 | 3 | 3 |

Merci d'avoir lu sur le broyeur de bois. Si vous êtes intéressé par nos machines ou si vous avez des questions, n'hésitez pas à nous contacter. Vous pouvez nous faire part de vos exigences spécifiques avant de commander un broyeur de bois. Pour protéger les intérêts de nos clients, nous sélectionnerons la machine la plus adaptée pour vous. Tous les clients intéressés par nos machines sont également les bienvenus pour visiter notre usine. Nous espérons établir une relation de coopération avec vous.