O triturador de madeira tipo tambor pode cortar troncos, galhos, tábuas, bambu, talos de algodão e outras matérias-primas de fibra de madeira ou não madeira em fatias de especificação uniforme (20-40mm de comprimento, 3-5mm de espessura), com uma taxa de qualificação superior a 97%. É amplamente utilizado em fábricas de papel, fábricas de aglomerado, fábricas de MDF de média e alta densidade, usinas de energia de biomassa, bases de exportação de chips de madeira, entre outros.

Vantagens da máquina de fazer lascas de madeira

- Forte adaptabilidade: pode ser instalada e utilizada em diferentes ambientes geográficos e condições climáticas sem ser afetada pelas estações.

- Sem instalação de fundação: o equipamento pode ser colocado em uso dentro de 1-2 dias após a chegada, economizando 10-15 dias.

- Economia de custos: a não construção de fundação pode economizar aos usuários cerca de $500-2000 em despesas de mão de obra e materiais (dependendo do modelo).

- Instalação flexível e conveniente: não é necessário fixar o local de instalação, fácil ajuste, melhora a flexibilidade e mobilidade do equipamento.

- Direção de descarga ajustável: equipado com um segundo dispositivo de descarga, a direção de descarga pode ser ajustada de forma flexível de acordo com as necessidades.

- Grande produção: capacidade de processamento diária de 30-300 toneladas, para se adaptar às necessidades de produção de diferentes usuários.

- Fácil operação: design de estrutura razoável, fácil operação e manutenção, adequado para todos os tipos de usuários.

Estrutura principal da máquina de desbaste de madeira

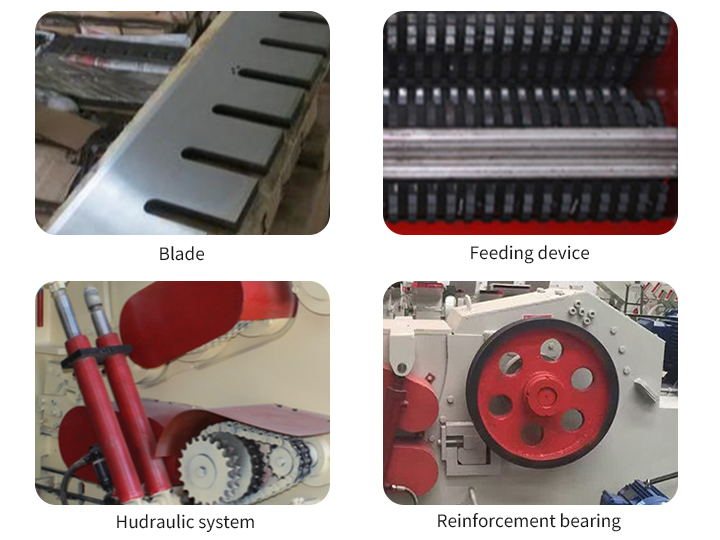

O triturador de madeira tipo tambor consiste em uma máquina principal soldada de chapa de aço de alta resistência, sistema de ferramentas de corte, rolos de alimentação superiores e inferiores, correia transportadora, entrada e saída, motor e sistema hidráulico.

Com uma estrutura robusta, operação suave e cooperação sinérgica de todas as partes, ele pode completar de forma eficiente a operação de desbaste de madeira e é adequado para uma variedade de condições de trabalho.

Princípio de funcionamento do triturador de madeira tipo tambor

O triturador de madeira em pedaços realiza a transformação da matéria-prima em lascas de madeira refinadas em três etapas, com alta eficiência e consumo de energia controlado:

Pressurização de alimentação hidráulica

- A matéria-prima é alimentada através de uma ampla esteira transportadora, e o sistema hidráulico de rolos duplos compacta e avança automaticamente o material a uma velocidade uniforme.

- Superar a resistência à deformação dos galhos garante a estabilidade da alimentação contínua.

- Ajuste inteligente da folga de pressão do rolo, adequado para todos os tipos de matérias-primas com diâmetro ≤ 350mm.

Corte dinâmico multi-lâminas

- O tambor de faca central integra um conjunto de facas voadoras de liga de alta resistência, girando a uma alta velocidade de 960 rpm.

- A lâmina adota um layout espiral radial, que adere à superfície da matéria-prima durante todo o processo de corte.

- O fatiamento em camadas de baixa resistência é alcançado, reduzindo significativamente as taxas de lascas e prolongando a vida útil da ferramenta.

Saída de classificação por ciclone

- Os pedaços de madeira cortados penetram pelos buracos da tela do tambor da faca e são transportados de forma direcional pelo fluxo de ar de alta velocidade e pressão negativa gerado pelo impulsor da faca.

- A tela de classificação embutida separa automaticamente as lascas oversized, e as lascas qualificadas são limpidamente expelidas através do duto de ar fechado.

- As impurezas são retornadas à área de britagem para processamento secundário, a fim de garantir que o diâmetro da peça final esteja preciso e dentro do padrão (erro de ±1mm).

Trituradores de madeira podem ser posteriormente esmagados em cavacos de madeira adicionando um triturador martelo de madeira na extremidade traseira da máquina, e então usados para fabricação de carvão e outras operações.

Produto acabado que você pode obter

O produto final produzido por este triturador de madeira em tambor possui tamanho de partícula uniforme, textura fina e superfície lisa, que pode ser amplamente utilizado em marcenaria, fabricação de papel e outros campos.

Parâmetros do triturador de madeira de tambor

| Modelo | SL215 | SL216 | SL218 | SL2113 |

| Tamanho da matéria-prima (mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Número de facas (peça) | 2 | 2 | 2 | 2 |

| Velocidade de rotação da faca (rpm) | 592 | 590 | 650 | 500 |

| Diâmetro da matéria-prima (mm) | 160 | 230 | 300 | 450 |

| Tamanho do lasca de madeira (mm) | 30 | 30 | 30 | 38 |

| Capacidade (t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Potência do motor principal (kw) | 45 | 55 | 110 | 200-250 |

| Potência do motor do rolo alimentador (kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Potência do motor da bomba de óleo (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Peso da máquina (kg) | 3590 | 5030 | 7000 | 11840 |

| Tamanho da máquina (mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Potência do motor do transportador (kw) | 3 | 3 | 3 | 3 |

Obrigado por ler sobre o triturador de madeira. Se você estiver interessado em nossas máquinas ou tiver alguma dúvida, sinta-se à vontade para entrar em contato conosco. Você pode nos informar requisitos específicos antes de encomendar um triturador de madeira. Para proteger os interesses de nossos clientes, selecionaremos a máquina mais adequada para você. Todos os clientes interessados em nossas máquinas também são bem-vindos a visitar nossa fábrica. Esperamos estabelecer uma relação de cooperação com você.