El astillador de tambor puede cortar troncos, ramas, tablones, bambú, tallos de algodón y otras materias primas de fibra de madera o no madera en rebanadas de especificación uniforme (20-40 mm de longitud, 3-5 mm de grosor), con una tasa de calificación de más del 97%. Se utiliza ampliamente en fábricas de papel, fábricas de tableros de partículas, fábricas de tableros de fibra de media y alta densidad, plantas de energía de biomasa, bases de exportación de astillas de madera, entre otros.

Ventajas de la máquina para hacer astillas de madera

- Fuerte adaptabilidad: se puede instalar y utilizar en diferentes entornos geográficos y condiciones climáticas sin verse afectada por las estaciones.

- Sin instalación de cimientos: el equipo se puede poner en uso dentro de 1-2 días después de la llegada, ahorrando 10-15 días.

- Ahorro de costos: no construir cimientos puede ahorrar a los usuarios entre $500 y $2000 en gastos de mano de obra y materiales (dependiendo del modelo).

- Instalación flexible y conveniente: no es necesario fijar el sitio de instalación, fácil ajuste, mejora la flexibilidad y movilidad del equipo.

- Dirección de descarga ajustable: equipado con un segundo dispositivo de descarga, la dirección de descarga se puede ajustar de manera flexible según las necesidades.

- Gran producción: capacidad de procesamiento diaria de 30-300 toneladas, para adaptarse a las necesidades de producción de diferentes usuarios.

- Fácil operación: diseño de estructura razonable, fácil operación y mantenimiento, adecuado para todo tipo de usuarios.

Estructura principal de la máquina de astillado de madera

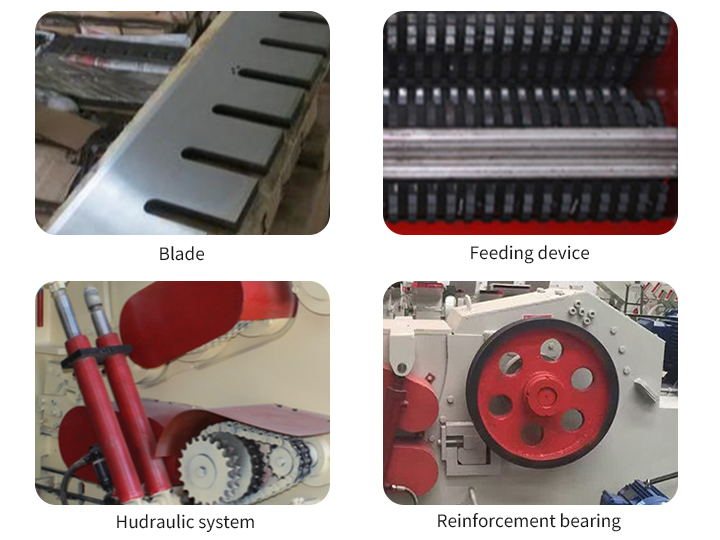

El astillador de tambor consiste en una máquina principal de placa de acero de alta resistencia soldada, sistema de herramientas de corte, rodillos de alimentación superiores e inferiores, cinta transportadora, entrada y salida, motor y sistema hidráulico.

Con una estructura robusta, operación suave y cooperación sinérgica de todas las partes, puede completar de manera eficiente la operación de astillado de madera y es adecuada para una variedad de condiciones de trabajo.

Principio de funcionamiento de la trituradora de madera de tambor

La astilladora de tambor transforma la materia prima en astillas de madera refinadas en tres etapas, con alta eficiencia y un consumo de energía controlado.

Presurización de alimentación hidráulica

- La materia prima se alimenta a través de una cinta transportadora ancha, y el sistema hidráulico de doble rodillo compacta y avanza automáticamente el material a una velocidad uniforme.

- Superar la resistencia a la deformación de las ramas asegura la estabilidad de la alimentación continua.

- Espacio de presión de rodillo ajustable inteligente, adecuado para todo tipo de materias primas con diámetro ≤ 350 mm.

Corte dinámico multiblade

- El tambor de cuchillas central integra un conjunto de cuchillas voladoras de aleación de alta resistencia, que gira a alta velocidad de 960 rpm.

- La cuchilla adopta un diseño en espiral radial, que se adhiere a la superficie de la materia prima durante todo el proceso de corte.

- Se logra un corte en capas de baja resistencia, reduciendo significativamente las tasas de virutas y extendiendo la vida útil de la herramienta.

Salida de clasificación por ciclón

- Las astillas de madera cortadas penetran a través de los agujeros de la pantalla del tambor de cuchillas y son transportadas de manera direccional por el flujo de aire a alta velocidad y presión negativa generado por el impulsor de cuchillas.

- La pantalla de clasificación incorporada separa automáticamente las virutas sobredimensionadas, y las virutas calificadas se expulsan limpiamente a través del conducto de aire cerrado.

- Las impurezas se devuelven al área de trituración para un procesamiento secundario para asegurar que el diámetro de la pieza terminada sea preciso y esté dentro de los estándares (±1 mm de error).

Las astilladoras de madera pueden triturarse aún más en astillas de madera añadiendo un triturador pulverizador de martillos de madera en la parte trasera de la máquina, y luego utilizarse para la fabricación de carbón y otras operaciones.

Producto terminado que puedes obtener

El producto terminado producido por esta astilladora de madera de tambor tiene un tamaño de partícula uniforme, una textura fina y una superficie lisa, que puede ser ampliamente utilizado en la carpintería, la fabricación de papel y otros campos.

Parámetros de la astilladora de tambor

| Modelo | SL215 | SL216 | SL218 | SL2113 |

| Tamaño del material en bruto (mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Número de cuchillos (pieza) | 2 | 2 | 2 | 2 |

| Velocidad de rotación de la cuchilla (rpm) | 592 | 590 | 650 | 500 |

| Diámetro de materia prima (mm) | 160 | 230 | 300 | 450 |

| Tamaño de astillas de madera (mm) | 30 | 30 | 30 | 38 |

| Capacidad (t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Potencia del motor principal (kw) | 45 | 55 | 110 | 200-250 |

| Potencia del motor del rodillo de alimentación (kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Potencia del motor de la bomba de aceite (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Peso de la máquina (kg) | 3590 | 5030 | 7000 | 11840 |

| Tamaño de la máquina (mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Potencia del motor del transportador (kw) | 3 | 3 | 3 | 3 |

Gracias por leer sobre la astilladora de madera. Si está interesado en nuestras máquinas o tiene alguna pregunta, no dude en ponerse en contacto con nosotros. Puede informarnos sobre requisitos específicos antes de ordenar una astilladora de madera. Para proteger los intereses de nuestros clientes, seleccionaremos la máquina más adecuada para usted. Todos los clientes interesados en nuestras máquinas también son bienvenidos a visitar nuestra fábrica. Esperamos establecer una relación de cooperación con usted.