With rising environmental standards and demand for clean energy, the charcoal briquette processing line is emerging as a stable and profitable green industry. For small and medium-sized entrepreneurs and eco-friendly enterprises, understanding production line costs and benefits is crucial.

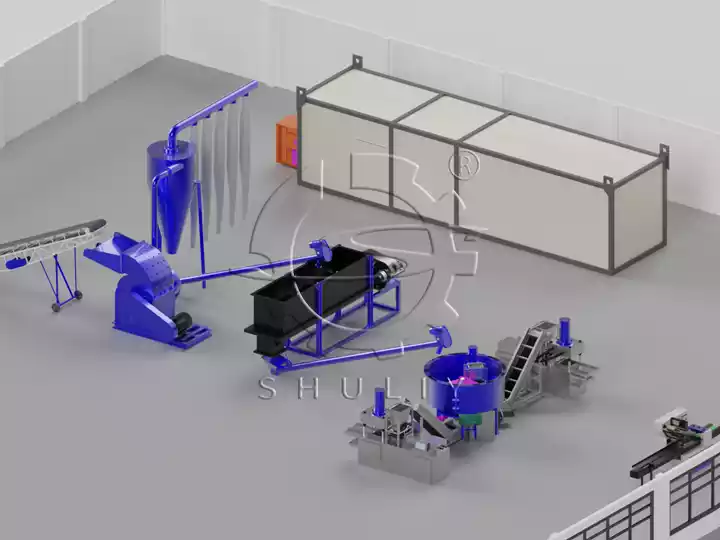

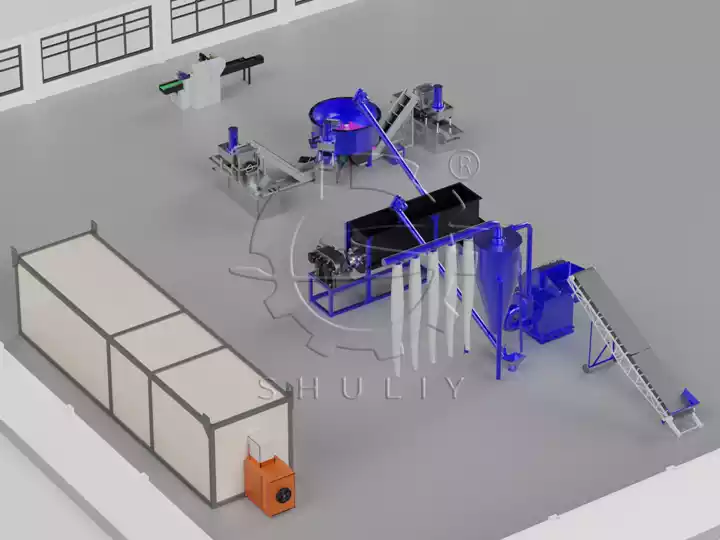

Charcoal briquette processing line composition

A complete charcoal briquette production line primarily includes: crusher, pulverizer, mixer, molding machine, dryer, and packaging equipment. The production process is: raw material crushing → pulverization into powder → uniform mixing → compression molding → drying and setting → packaging and shipment.

Modern equipment enables continuous production, processing 200–1000 kg of raw material per hour. Operating 8–10 hours daily yields 1–8 tons of finished charcoal. Production lines can be flexibly adjusted based on raw material type (wood chips, coconut shells, coal dust, etc.) and output requirements.

Investment costs and returns

Equipment pricing varies by capacity and automation level. A small-scale production line costs approximately $5,000–15,000 USD, while medium-to-large-scale lines can reach $30,000–80,000 USD. Beyond equipment costs, additional expenses include raw material procurement, site construction, and labor fees.

Taking a small-scale line as an example: raw material costs for finished charcoal are approximately $100–150 per ton, with market prices around $200–300 per ton. Daily output of 2–3 tons yields monthly profits of $3,000–6,000, typically achieving payback within 6–12 months.

Market prospects and applications

Coal-stick charcoal is suitable for household fuel, barbecuing, catering, and industrial heating applications. Market demand continues to grow, driven by environmental policies and clean energy promotion. Simultaneously, this charcoal briquettes making production line features simple operation and low energy consumption, making it ideal for startups and small factories to launch green economy projects.