The hookah charcoal briquetting machine is a kind of molding equipment to press charcoal powder or coal powder into regular lump or flake charcoal with high pressure. It is widely used in the production of carbon products such as water-smoked charcoal, barbecue charcoal, hotel heating charcoal and so on.

We produce shisha charcoal equipment with hydraulic or mechanical dual-mode pressing method. The machine not only has high molding efficiency, but also has high density and smooth appearance of the finished charcoal, which can meet the diversified demands of the current market for high quality hookah charcoal.

With the worldwide popularization of hookah culture, this hookah charcoal briquetting machine has a broad market prospect and is the best choice for charcoal product processing plants and business projects.

Advantages of hookah charcoal tablet machine

- The pressed hookah charcoal has high hardness, is not easy to break, and has regular molding, which is suitable for long time storage and transportation.

- The finished charcoal has high density and carbon content, which can be ignited quickly and burn for a long time, and can maintain constant heat, which makes the experience of using the charcoal good.

- Supporting a variety of customized shapes, such as round, cubic, hexagonal, etc., to meet different market preferences and packaging needs.

- Some models are equipped with automatic charging and demolding functions, which greatly improves production efficiency and saves labor costs.

- The machine body is made of high-quality steel, with high-performance hydraulic/mechanical system, smooth operation, easy maintenance and long service life.

- It can press a variety of carbon powder raw materials such as coconut shell charcoal, charcoal powder, coal powder, etc., with strong raw material adaptability.

Raw materials for making hookah charcoal

The best and most commonly used raw material for making hookah charcoal is coconut shell charcoal powder. In addition to this, natural woods such as bamboo, oak, teak, apple, and cherry wood are also used. Shisha charcoal can be mixed with different tobacco flavors and spices to obtain hookahs of various flavors.

These raw materials need to be crushed to less than 3mm by a crusher machine, then 5% of the binder is added and put into a wheel mill for mixing to ensure that the moisture content after mixing is approximately 25%. The finer the powder, the smoother and more beautiful the finished product.

3 Types of hookah charcoal briquetting machine

After decades of experience in hookah charcoal production and customer service, our hookah charcoal tablet press has been continuously optimized, and finally, three hookah charcoal tablet presses can meet the needs of most customers.

They are mechanical shisha charcoal-making machines, hydraulic hookah charcoal tablet machines, and rotary hookah charcoal machines.

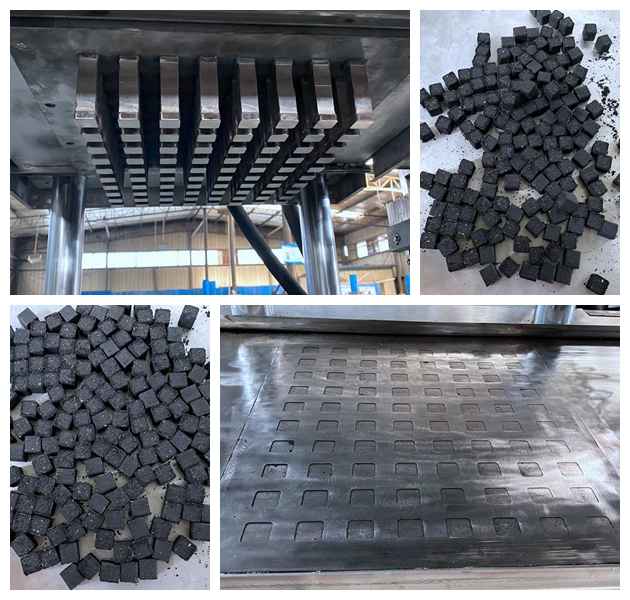

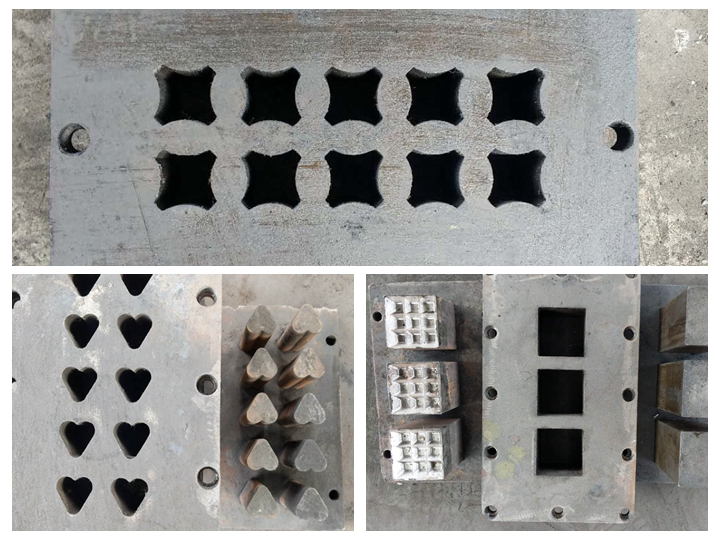

All types of hookah charcoal tablet presses can customize different shapes of molds according to customer needs. In addition to the common circles and squares on the market, letters, logos, contact information, and other information can also be added to the molds according to customer requirements.

The specifications of the finished products are generally as follows: diameter of the round piece: 28mm, 33mm, 34mm, 30mm; square shape: side length 20mm or 25mm.

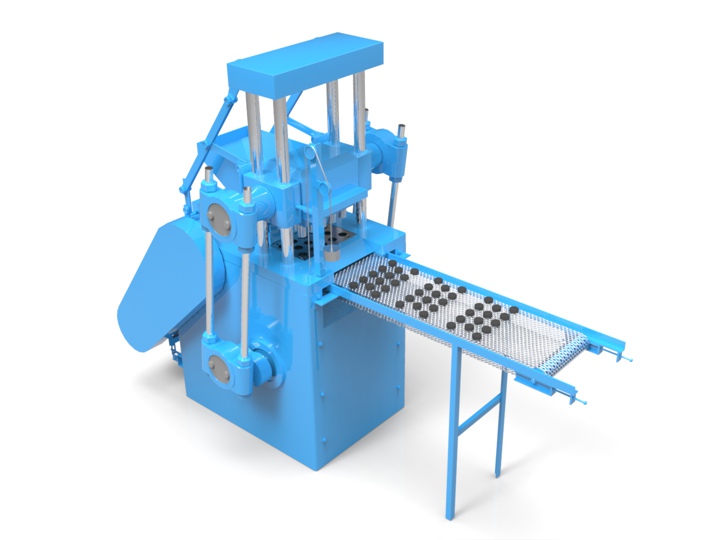

Mechanical hookah charcoal briquetting machine

This hookah charcoal tablet press is mainly composed of a motor, a transmission device, a mold, and a discharge conveyor belt. The motor drives the transmission device to press the carbon powder into carbon blocks of different shapes.

This type is the best-selling hookah charcoal briquetting machine, with a simple structure, large output, high production efficiency, and large-scale production.

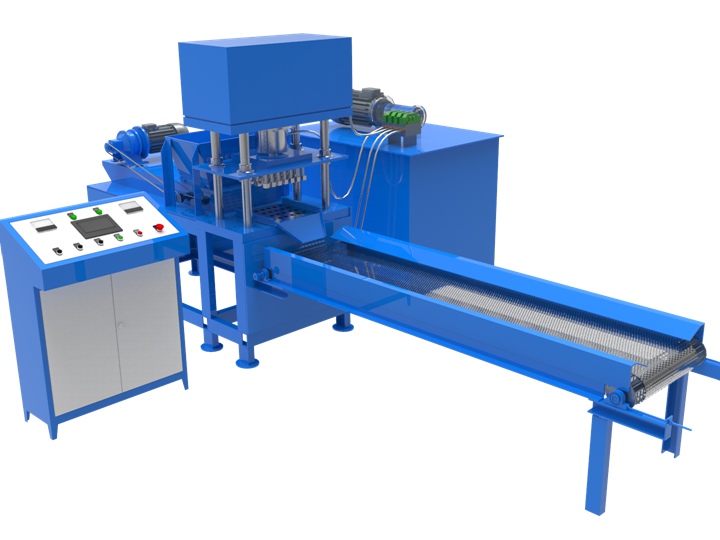

Hydraulic shisha charcoal briquetting machine

This is a new type of hookah charcoal briquetting machine. The main structure is composed of a frame, hydraulic system, PLC control system, and discharge conveyor belt.

The principle of this machine is also to use high pressure to compress the carbon powder, but the hydraulic briquetting machine can provide more pressure, and the pressed hookah charcoal has a better molding effect, higher density, and longer burning time.

- Intelligent control system It is convenient for the user to adjust the pressure, pressing speed, and other parameters, and the size of the pressed hookah charcoal can also be fine-tuned to a certain extent.

- A mixing device is equipped in the feed port to prevent the material from sticking and is beneficial to the unloading.

- The use of stainless steel material can effectively prevent wear and corrosion, and the processing efficiency is very fast.

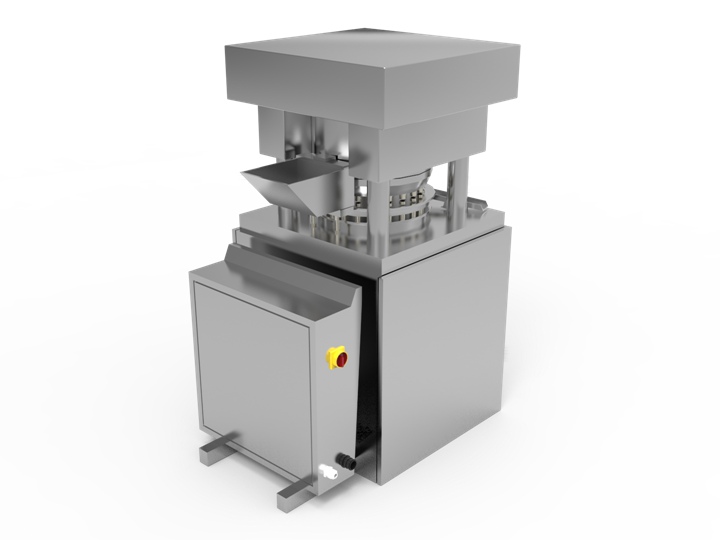

Rotary hookah charcoal briquetting machine

The pressing mode of the rotary hookah charcoal briquetting machine is no longer up-and-down pressing, but rotary pressing.

This machine can achieve continuous feeding and continuous output of hookah charcoal. The processing efficiency is the highest among the three machines.

Shisha charcoal briquette press machine working principle

These types of hookah charcoal briquetting machines all work on a similar principle and consist of the following main steps:

- Material preparation and conveying the mixed raw materials through the feeding system to the pressing area of the hookah charcoal briquetting machine.

- the raw materials are squeezed and extruded by high-pressure rollers to form granules or lumps of specified shapes. The shape and density of the molding can be controlled by adjusting the roll spacing and pressure.

- After molding, the shisha charcoal briquettes are cut into suitable sizes. The finished product is then collected through a conveyor system for subsequent packaging or storage.

Hookah charcoal briquetting machine technical parameters

| Model | Power(KW) | Capacity(Pcs/min) | Pressure(T) | Weight(KG) | Dimension(mm) |

| Mechanical | 7.5 | 280 | 20 | 1700 | 1700x1500x1200 |

| Hydraulic | 13 | 300 | 80 | 1000 | 2500x750x2300 |

| Rotary | 7.5 | 570 | 120 | 1500 | 800x900x1650 |

Molds and applications of shisha charcoal briquettes

Shisha, or hookah in English, is a tobacco product that is smoked after filtering water or other liquids. It is popular in Eastern Mediterranean countries such as Turkey, Syria, Lebanon, and Egypt, and is also common in Jordan and the Gulf region.

When smoking hookah, hookah charcoal is used to heat tobacco to produce smoke, so this puts high demands on hookah charcoal. Hookah charcoal is required to be hard and non-divergent, high in density, easy to ignite, long burning time, and evenly heated.

Hookah charcoal originated in the Middle East, where a long history of hookah culture and tradition developed. Smoking hookah is seen as a way to socialize, have fun, and relax, and people often use hookah charcoal at home, in cafes, or social settings.

Feel free to contact us at any time

If you are looking for coal powder casting equipment, then you can also choose Shuliy’s coal briquette machine, barbecue charcoal briquette machine, or honeycomb coal machine. (Related article: charcoal briquette extruder, BBQ coal balling machine, honeycomb charcoal molding machine)

Please do not hesitate to contact our sales team for more detailed information about our hookah charcoal tablet press machine. We will provide you with a personalized consultation service to ensure that the equipment you choose is perfectly suited to your needs. Make your hookah charcoal production process more efficient and smooth with our assistance.