The wood hammer mill crusher can pulverize many kinds of raw materials such as tree branches, waste wood boards, corn cobs, straw and so on into sawdust shape. Through the modular screen design (sieve hole 20-120 mesh adjustable), the raw material can be converted into 0.2-3mm high uniformity wood chips (integrity rate>95%) at one time.

The equipment has low investment cost, low energy consumption, high output and convenient use and maintenance. It is an important auxiliary equipment for the production of edible fungus planting, wood chip board, high density board and biomass pellet, etc. It is favored by users in agriculture and renewable resources processing industry.

Applications of wood sawdust making machine

- Crushing wood, branches and trimmings to make sawdust for board making or granulation.

- Crushing corn cobs, straw, pasture and other crop residues, used as livestock feed or land fertilizer.

- Process waste paper to produce recycled paper, realizing environmental reuse.

- Crushed raw materials can be further made into charcoal or biomass fuel.

- It can be used as pre-treatment equipment for raw material volume reduction, easy transportation or sale.

Hammer crusher structure and working principle

Structure: The wood hammer mill crusher is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatility. Its structure consists of three parts: feed inlet, crushing chamber (rotor, hammer, screen, tooth plate), and discharge part (fan, collecting drum, cyclone, and dust collecting bag).

Principle: This wood hammer mill crusher mainly relies on impact to crush materials when it works.

- In the crushing process, the material enters the crusher and is impacted by the high-speed rotating hammer to be broken.

- The crushed material obtains kinetic energy from the hammerhead and hits the screen at high speed.

- At the same time, the materials will quickly collide with each other and be broken in many places.

When the material hits the screen, the material smaller than the mesh diameter is discharged, and the larger material will continue to be impacted by the hammer, ground, squeezed, and broken until it meets the requirements and is discharged.

Raw materials of wood hammer mill crusher

The hammer crusher machine is suitable for processing a variety of soft and small-sized raw materials, including coconut shells, chipboards, wood pallets, wood shavings, twigs, tree strips, corn stalks, thin wood panels, and medicinal herbs.

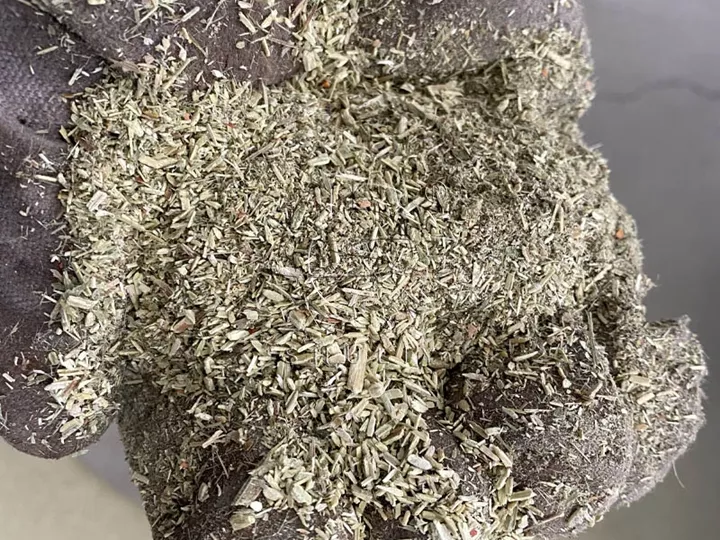

Machine sieves and finished sawdust you can get

Depending on the fineness and size of the finished product, we can equip sieves with different aperture sizes and also accept customized orders.

Wood shredder machine core advantages

- Wide range of applications: it can pulverize many kinds of soft and small-sized materials.

- Simple structure: reasonable design, compact structure, easy to operate and maintain.

- High crushing efficiency: one-time molding, large output, suitable for large-scale production.

- Low energy consumption: relatively low operating energy consumption, saving production costs.

- Adjustable discharge size: the screen can be replaced, according to the need to control the size of the finished product.

- Good economic efficiency: small investment, quick return, suitable for small and medium-sized processing plants.

Parameters of hammer grinding machine

| Model | WD-60 | WD-70 | WD-80 | WD-90 | WD-1000 | WD-1300 |

| Power(kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Hammers(pcs) | 30 | 40 | 50 | 50 | 105 | 105 |

| Fan(kw) | 7.5 | 7.5 | 11 | 22 | ||

| Dust remover(pcs) | 5 | 5 | 5 | 5 | 14 | 14 |

| Cyclone diameter(M) | 1 | 1 | 1 | 1 | 1 | 1 |

| Capacity (T/h) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

Successful case of hammer miller shredder

- A customer from Southeast Asia originally owned a large-scale paper mill, and suffered from the inability to deal with a large amount of waste paper.

- By watching our YouTube video, he learned about the operating effect of the wood hammer mill and the working condition of the whole production line, and finally decided to purchase the model 1000 wood hammer mill crusher production line.

- After put into use, the customer saves more than 100 tons of paper-making raw materials per month by crushing waste paper, not only reduces the cost, but also develops new products of renewable paper, which is welcomed by the local market and creates considerable profits.

Tips about the wood hammer mill crusher

- Check before starting the machine: make sure that all parts are intact, the pins are not off, the bolts are not loose, the speed is reasonable, the lubrication parts have oil, and the rotating parts are not stuck.

- Remove foreign matter: the raw materials should not contain metal, sand and gravel and other debris, in order to prevent damage to machine parts.

- Operation norms: the operator should stand on the side of the feeding port, it is forbidden to put the hand into the machine, and the cover should not be opened during the running process.

- No-load start: make sure the wood hammer mill crusher machine steering is correct before starting, idle running for 2-3 minutes, and make sure the operation is smooth before feeding the materials evenly.

- Uniform feeding: no load start; if there is a powder spraying phenomenon, you can accelerate the feeding speed, and add water appropriately, but avoid overloading the motor.

- The feeding port is blocked: it is forbidden to feed the material forcibly by hand, wooden stick or iron bar.

- Regular maintenance: after running for about 500 hours, the bearings should be cleaned and the lubricating oil should be replaced in time.

- Abnormal handling: if there is any abnormal sound during operation, it should be stopped immediately for inspection and troubleshooting.

- Hammer head replacement: the hammer head can be switched direction or replaced with a new hammer head after wear.

- Shutdown operation: idle for 2-3 minutes before shutdown, close the feed regulator and remove the remaining materials in the machine.

Feel free to contact us at any time

We also have larger shredders available for larger outdoor crushing projects, such as large wood pallet boards, log timber crushing, and more. (Related Article: Comprehensive Crusher | Multi-functional crushing equipment.)

If you have any questions or need further information, please feel free to contact us and we will be happy to provide you with detailed information. In addition, we warmly welcome you to visit our factory to experience our advanced production process and machine performance. Face-to-face communication with us is the most direct way to understand our products. We are looking forward to establishing co-operation with you!