木锤磨粉机可以将多种原材料如树枝、废木板、玉米芯、稻草等粉碎成木屑形状。通过模块化筛网设计(筛孔20-120目可调),原材料可以一次性转化为0.2-3mm高均匀性的木片(完整率>95%)。

该设备投资成本低,能耗低,产出高,使用和维护方便。它是食用菌种植、木屑板、高密度板和生物质颗粒等生产的重要辅助设备。受到农业和可再生资源加工行业用户的青睐。

木屑制粒机的应用

- 破碎木材、树枝和修剪物以制成用于板材制造或颗粒化的木屑。

- 破碎玉米棒、秸秆、牧草和其他作物残余,作为牲畜饲料或土地肥料。

- 处理废纸以生产再生纸,实现环境再利用。

- 破碎的原材料可以进一步制成木炭或生物质燃料。

- 可作为原材料减量化的预处理设备,便于运输或销售。

锤式破碎机的结构和工作原理

结构:木材锤式破碎机是目前最广泛使用的研磨机类型,具有相对较高的电气产品产量和良好的多功能性。其结构由三部分组成:进料口、破碎室(转子、锤头、筛网、齿板)和出料部分(风机、集料筒、旋风分离器和集尘袋)。

原理:该木材锤式破碎机在工作时主要依靠冲击来破碎物料。

- 在破碎过程中,材料进入破碎机,受到高速旋转锤头的冲击而破碎。

- 破碎的材料从锤头获得动能,并以高速撞击筛网。

- 同时,材料会迅速相互碰撞,并在多个地方被破碎。

当物料撞击筛网时,小于网孔直径的物料被排出,而较大的物料将继续受到锤子的冲击,被研磨、挤压和破碎,直到满足要求并被排出。

木材锤式破碎机的原材料

锤式破碎机适合处理多种软质和小尺寸的原材料,包括椰子壳、刨花板、木托盘、木屑、树枝、树条、玉米秆、薄木板和药材。

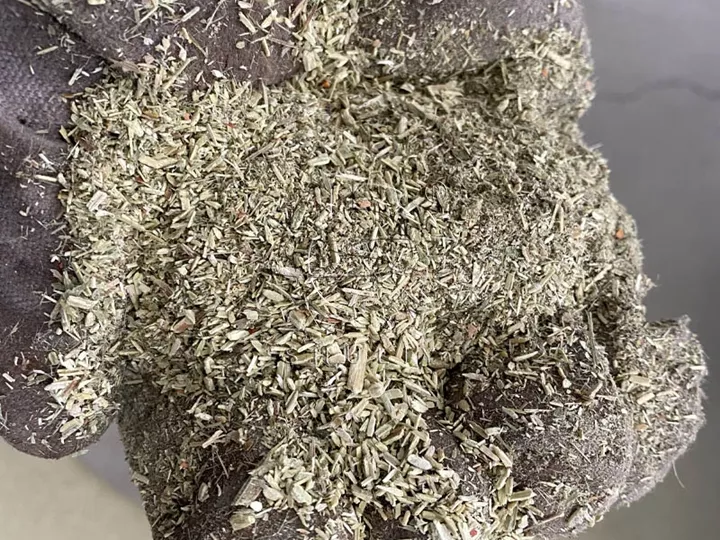

您可以获得机器筛网和成品锯末

根据成品的细度和大小,我们可以配备不同孔径的筛子,也接受定制订单。

木材粉碎机的核心优势

- 广泛的应用范围:可以粉碎多种软质和小型材料。

- 结构简单:设计合理,结构紧凑,操作和维护简单。

- 高破碎效率:一次成型,产量大,适合大规模生产。

- 低能耗:相对较低的操作能耗,节省生产成本。

- 可调节的排料尺寸:可以更换筛网,根据需要控制成品的大小。

- 良好的经济效益:投资少,回报快,适合中小型加工厂。

锤式磨床的参数

| 型号 | WD-60 | WD-70 | WD-80 | WD-90 | WD-1000 | WD-1300 |

| 功率(千瓦) | 22 | 30 | 37 | 55 | 75 | 90 |

| 锤子(个) | 30 | 40 | 50 | 50 | 105 | 105 |

| 风扇(千瓦) | 7.5 | 7.5 | 11 | 22 | ||

| 除尘器(个) | 5 | 5 | 5 | 5 | 14 | 14 |

| 气旋直径(米) | 1 | 1 | 1 | 1 | 1 | 1 |

| 产能(吨/小时) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

锤式粉碎机成功案例

- 来自客户 东南亚 最初拥有一家大型纸厂,但无法处理大量废纸。

- 通过观看我们的视频,他了解了木材锤磨机的操作效果和整个生产线的工作状况,最终决定购买1000型号的木材锤磨机破碎生产线。

- 投入使用后,客户每月通过粉碎废纸节省了超过100吨的造纸原材料,不仅降低了成本,还开发了可再生纸的新产品,受到当地市场的欢迎,并创造了可观的利润。

木锤磨粉机的提示

- 在启动机器之前检查:确保所有部件完好无损,销钉没有脱落,螺栓没有松动,转速合理,润滑部件有油,旋转部件没有卡住。

- 去除异物:原材料不得含有金属、沙子和碎石等杂物,以防止损坏机器部件。

- 操作规范:操作员应站在进料口的一侧,禁止将手放入机器中,运行过程中不得打开盖子。

- 空载启动:确保木材粉碎机的方向正确后再启动,空转2-3分钟,确保操作顺畅后再均匀投料。

- 均匀喂料:无负载启动;如果出现喷粉现象,可以加快喂料速度,并适当加水,但要避免过载电机。

- 进料口被堵:禁止用手、木棍或铁棒强行喂料。

- 定期维护:运行约500小时后,应及时清洁轴承并更换润滑油。

- 异常处理:如果在操作过程中有任何异常声音,应立即停止检查和排除故障。

- 锤头更换:锤头磨损后可以更换方向或更换新的锤头。

- 停机操作:停机前空转2-3分钟,关闭进料调节器并清除机器内剩余物料。

随时欢迎联系我们

我们还有更大的破碎机可用于较大的户外破碎项目,例如大型木托板、原木破碎等。(相关文章:综合破碎机 | 多功能破碎设备。)

如果您有任何问题或需要进一步的信息,请随时与我们联系,我们将很高兴为您提供详细的信息。此外,我们热烈欢迎您参观我们的工厂,亲身体验我们的先进生产工艺和机器性能。与我们面对面的沟通是了解我们产品的最直接方式。我们期待与您建立合作关系!