Charcoal is not formed by burning wood, usually charcoal is the product of incomplete combustion of wood, which retains the original structure of wood. Charcoal has a wide range of uses, such as painting, makeup, medicine, gunpowder, carburizing, etc. There are many raw materials for producing charcoal.

Raw materials for producing charcoal

In theory, anything containing carbon can be used to make carbon, so the raw materials for making charcoal are very wide, such as rice husk, cotton husk, corn cob, corn stalk, sorghum stalk, beanstalk, and other woody scraps; Bamboo chips, rice husks, coconut shells and other machine-made charcoal are the best, and spherical machine-made charcoal is the most flammable and durable.

The formation process of producing charcoal

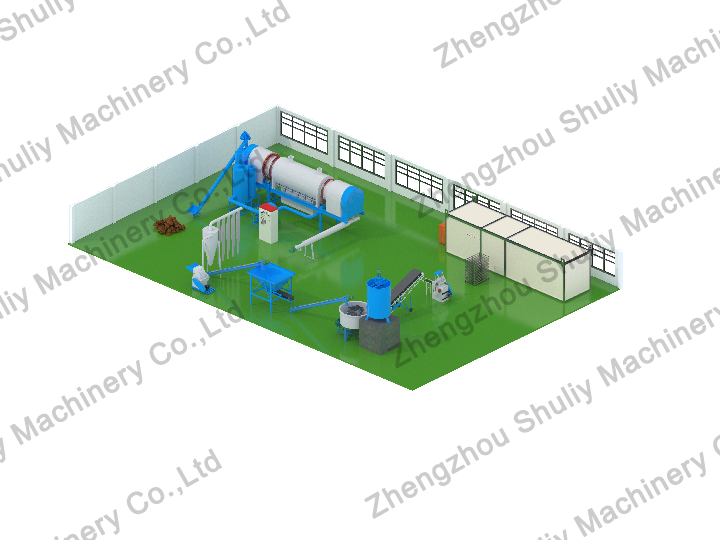

The above-mentioned materials are dried in a drying furnace into standard raw materials with appropriate dryness and humidity. After cooling, they enter the molding machine (rod making machine), and then undergo high temperature and high-pressure plasticization. There are various forms, generally brick and earth kilns) carbonization is the finished machine-made charcoal.

The composition of charcoal

Charcoal is mainly carbon, with very low ash content, and the calorific value is 27.21~333.49 MJ/kg. In addition, it also contains hydrogen, oxygen, nitrogen, and other components. Charcoal is a hydrophobic substance, and its specific gravity is generally 1.3~1.4. The calorific value depends on the carbonization conditions. The carbonization furnace is used for processing, and the heat is generally about 8000 kcal/kg.

Types of charcoal

white charcoal

black charcoal

activated charcoal

mechanism charcoal

Charcoal products are mainly divided into four categories: white charcoal, black charcoal, activated charcoal, and mechanism charcoal.

What is mechanism charcoal?

Machine-made charcoal is mainly made of sawdust, peanut shells, corn cobs, and other raw materials crushed into granules within 10mm by a sawdust pulverizer, dried in a dryer, and then put into a carbonization furnace for carbonization.

The difference between mechanism charcoal and other charcoal

1. Environmental protection: do not cut down trees, use bamboo and wood product waste to produce, and turn waste into treasure. The production of ordinary charcoal requires cutting down trees and destroying the ecological environment.

2. High energy: the fixed carbon content is about 80%, and the calorific value is 7500-8000kcal/kg, while the fixed carbon content of charcoal is low, and the calorific value is about 6500kcal/kg.

3. Clean and hygienic: no smoke and no carbon head, no sparks when burning, the residual ash naturally falls and does not float up during the combustion, and the residual ash is less than 3% or 6% after burning, which is flammable.

4. Regular shape, reasonable structure, easy to use: with uniform length and size, hollow or solid structure, which is conducive to burning and use.

5. Low water content, within 5%: ordinary charcoal has high water content.

6. The product does not contain chemical substances, is non-toxic, has no peculiar smell, no pollution, long burning time, and other advantages.