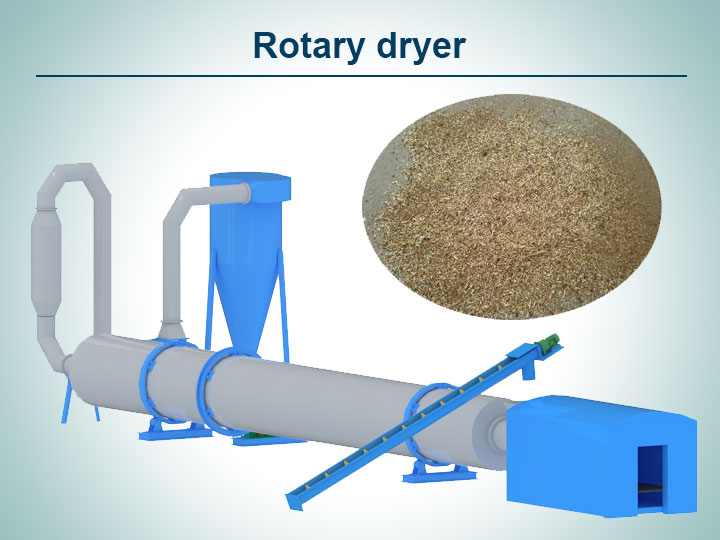

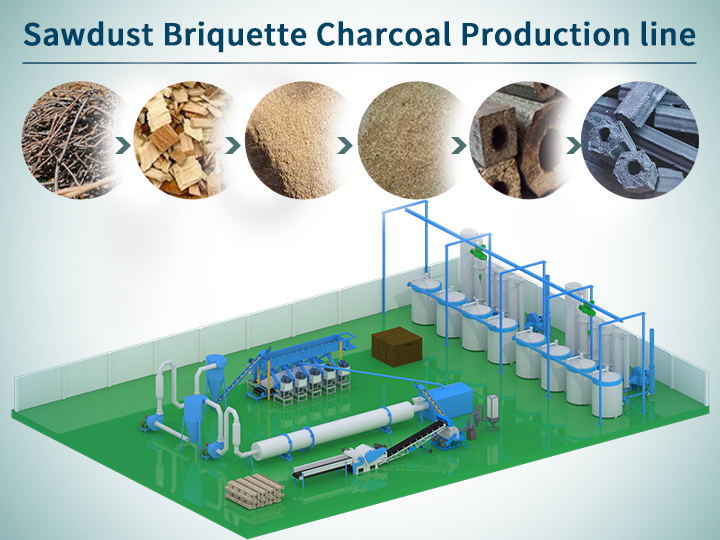

A sawdust drying machine is the drying equipment mainly for drying wet sawdust. Sawdust is often used for processing sawdust briquette, which is high-quality fuel. Generally, a sawdust briquette charcoal machine processes sawdust into sawdust briquette charcoal, and the production of sawdust briquette has high moisture requirements for sawdust, the moisture should be ≤12%, and the temperature of stick making is 180℃-200℃ so that the sawdust briquette can be resistant to burning. If the humidity of sawdust briquette charcoal is high, the produced wood chip sticks are easy to be scattered and not strong. For users, its production effectiveness is a matter of concern. Want to ensure the high production efficiency of the sawdust drying machine, how should we operate it?

Factors that affect the efficiency of sawdust drying machine

If you want to improve the production efficiency of a sawdust dryer, you should first understand what factors affect the efficiency of the sawdust dryer. Users who use sawdust dryers hope to achieve efficient sawdust drying and processing operations, but in actual production, sometimes there is a slow drying speed. After investigation and research, it is believed that there are many factors that affect the dryer

- The size of wood chip particles. When we dry sawdust materials, when the smaller the particle size of the material, the smaller the internal diffusion resistance, and the faster the drying; and large granular materials in the drying process is easy to form an air film layer, preventing the heat transfer of the inner layer of the material. Therefore, for large pieces of material before drying, we need to crush them properly.

- The uniform degree of feeding. At the same time, the staff’s even amount of feeding is also a prerequisite for achieving the even flow of materials, which can ensure the stability of the thermal regime of the dryer heat load on the one hand, so that the moisture of the materials after drying is consistent; on the other hand, it can also make the tail gas easy to grasp and control and ensure the drying quality.

- Sawdust humidity. The humidity of sawdust materials is too high, which will also affect the efficiency of drying and lengthen the drying processing time, so the sawdust can be properly dehydrated to improve the drying speed of the sawdust dryer.

- Loading capacity. Generally, dryers have different models, each model will be by the corresponding loading capacity, some producers save time on the strength of the products entering the equipment by drying more than the prescribed loading capacity; this will lead to slow rotation of the dryer, affecting the rotation rate of wood chips in the drying cylinder, resulting in uneven drying.

- Weather influence. The wood chips have strong water absorption, and the air humidity will increase the moisture content of the wood chips, and then the drying time needs to be adjusted and the drying strength needs to be enhanced.

- The insulation facilities of the equipment are not perfect. Inadequate insulation of the dryer will lead to a high rate of fuel loss and low drying efficiency, and the general drying equipment needs good insulation performance. The specific practice is to use angle steel and flat steel as the skeleton, rock wool as the insulation material, and seal the color steel plate outside.

Ways to improve the efficiency of sawdust drying machine

1. Under the condition of ensuring the nature of materials and normal operation of equipment, improves the drying efficiency and increases the output by increasing the supply of heat source, raising the temperature of the airflow in the sawdust dryer cylinder, and accelerating the evaporation of material moisture.

2. It can be achieved by reasonably increasing the lifting device in the sawdust dryer cylinder and increasing the contact area between the material and the hot air flow. The roller dryer is shipped.

3. For some temperature difference, is relatively large, especially in areas where the temperature is low, you can add insulation equipment to the sawdust dryer equipment to reduce the preheating time of the equipment and heat dissipation, so that the heat in the limited space of the greater aggregation, increase the drying temperature and speed up the drying of materials.

4. In addition to ensuring the flow speed of materials, reasonably adjusting the rotation speed of the sawdust dryer cylinder, speed up the rotation of the drum, improve the exchange speed of materials and heat flow, and enhance the drying efficiency. The length of the drum is also a major factor affecting the output, and the length exceeds the limited configuration, which will not only cause energy waste but also reduce the drying efficiency. General users in the optional model should pay attention to whether the optional drum length matches the drying output.

5. For some customers drying material moisture, is too large, affecting the premise of the sawdust dryer drying effect, you can consider adding dehydration equipment, and taking off excess water in the material, which reduces the amount of water evaporation in the material, reducing the evaporation time, making efficiency and increase production.

6. For part of the drying material particles, are too large, affecting the drying effect and the premise of the operating time, you can join the material crushing equipment so that the volume of the material is relatively reduced, and its heat will be relatively increased, so as to greatly enhance the force operating time and increase the drying output.

7. Sawdust dryer quality is also a major factor affecting the output. Good equipment whose sealing effect is good, the use of good insulation material can prevent heat loss in the drying process, while its collection effect is good, can quickly collect the dried material, to prevent the material in the cylinder for a long time reciprocal movement, increasing the drying time and reducing the quality of materials.