The belt-type continuous charcoal dryer machine is widely used for drying charcoal products such as barbecue charcoal and coal briquettes. It is also suitable for processing sheet-shaped, strip-shaped, block-shaped, and granular materials such as Chinese herbal medicine slices, fruit and vegetable slices, grains, agricultural by-products, aquatic products, feed, and chemical raw materials.

This continuous charcoal dryer uses a belt conveyor system to achieve continuous material input and output, resulting in high drying efficiency and stable output. It has been exported to multiple countries, including the United Kingdom, Indonesia, Argentina, Iraq, Mexico, Cameroon, and Sri Lanka. It is widely favored by companies in the food, pharmaceutical, agricultural, and charcoal product processing industries.

Continuous charcoal dryer performance characteristics

- Adjustable drying parameters: flexibly adjust airflow, heating temperature, material residence time, and feed rate to ensure optimal drying results.

- Flexible equipment configuration: optional belt cleaning system and material cooling system available to meet the process requirements of different materials.

- Energy-efficient and high-performance: utilizes hot air circulation, with most air reusable, significantly reducing energy consumption.

- Even hot air distribution: a unique air distribution device ensures uniform hot air distribution, maintaining consistent product quality.

- Multiple heat sources available: can use steam, thermal oil, electricity, coal (oil), or gas-fired hot air furnaces, adapting to various production conditions.

Principle of continuous charcoal dryer machine

The continuous charcoal dryer uses multi-layer belts woven from 3mm steel wire, driven by chains to prevent collisions and friction during operation, ensuring the integrity of the material.

The multi-layer structure (available in three or five layers) not only increases work efficiency by 3-5 times, but also reduces floor space and heat loss, and lowers exhaust emissions.

Hot air is blown upward from the bottom, with higher temperatures in the lower layers and lower temperatures in the upper layers, which better protects material quality while improving thermal energy utilization and reducing fuel consumption.

The continuous charcoal dryer supports multiple heating methods, including hardwood, charcoal, electric heating, and gas heating, to meet various production requirements. The belt material can be selected based on drying temperature: carbon steel (≤400°C) or stainless steel (≤600°C).

The conveyor belt operates at a speed range of 0.06–1 m/min, primarily comprising components such as the conveying system, hot air furnace, dust collection equipment, and exhaust fan. By flexibly adjusting temperature, airflow, and operating speed, efficient, uniform, and energy-saving continuous drying can be achieved.

What factors affect the drying effect?

During the material drying process, the drying effect is mainly affected by factors such as temperature, wind speed, drying time, and the uniformity of heat distribution.

If the hot air temperature is too low, it will result in excessive drying time; while excessive temperature can shorten the time, it may cause adverse reactions such as changes in material composition.

Therefore, it is necessary to reasonably control all parameters in production to ensure efficient, stable, and uniform drying effects.

Continuous charcoal dryer machine parameters

| Model | SL-6 | SL-8 | SL-10 | SL-12 | SL-16 | SL-20 | SL-24 | SL-30 |

| Width of Belt | 600mm | 800mm | 1000mm | 1200mm | 1600mm | 2000mm | 2400mm | 3000mm |

| Length of Drying Section | 6-12 | 6-12 | 6-16 | 8-16 | 8-22 | 10-26 | 12-30 | 12-40 |

| Length of Feeding Section | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Length of Transmitting Section | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Drying Area | 3.6-36㎡ | 4.8-48 ㎡ | 6-80 ㎡ | 7.2-96㎡ | 12.8-105.6 ㎡ | 20-260㎡ | 28.8-360 ㎡ | 36-600 ㎡ |

| Unit Number | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Interlamellar Spacing | 400-600 mm | 400-600 mm | 400-600 mm | 400-600 mm | 400-600 mm | 400-600 mm | 400-600 mm | 400-600 mm |

| Capacity | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ | 90-200 kg/㎡ |

| Temperature | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° | carbon steel≤400 C°, stainless steel≤600 C° |

| Transmission powder | 1.1-2.2 kW | 1.1-2.2 kW | 1.1-2.2 kW | 1.1-3kw | 1.5-3 kW | 1.5-4 kW | 3-7.5 kW | 5-11 kW |

Shuliy’s charcoal production machines

Shuliy is a company with ten years of experience in exporting charcoal processing machines, which can produce water-smoke hookah charcoal, barbecue charcoal, wood sawdust briquettes, and other products. Our charcoal production equipment is complete, from raw material processing to packaging and selling, and has the corresponding machine.

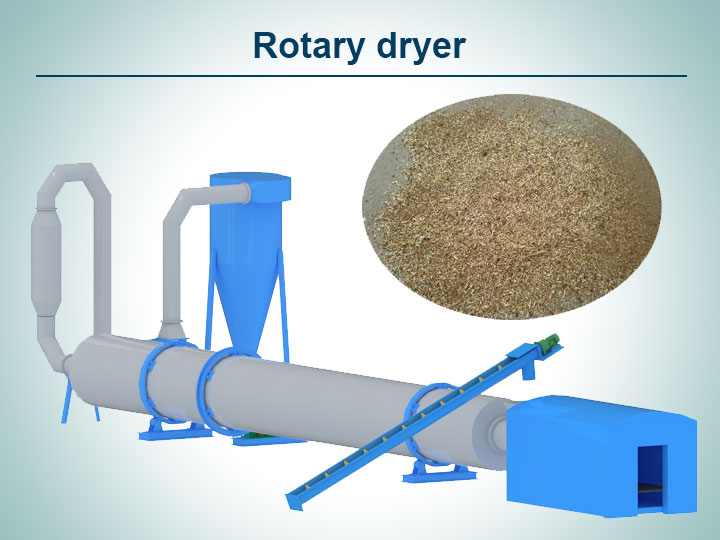

In addition to this continuous charcoal dryer, we have other types of drying equipment available, such as the drum rotary dryer and box-type drying rooms shown below:

Factory machine real shot

Contact us at any time

If you are a charcoal producer, we invite you to join us as a customer. We are committed to providing customized solutions and manufacturing the most suitable dryers to ensure that our products are perfectly integrated into your production process, creating greater value for you.