The box-type charcoal briquette drying machines are commonly used in the production and processing of charcoal and various types of shaped charcoal. This equipment achieves efficient, energy-saving, and environmentally friendly drying results through scientific temperature and humidity control. It can dry products quickly and uniformly without damaging the shape of the charcoal.

In addition to charcoal drying, it can also be widely used in the drying needs of various industries such as food, herbs, plants, and meat, making it a truly multi-purpose intelligent and environmentally friendly device.

After market testing, the box-type drying room has gained widespread popularity in countries such as Iran, South Africa, Nigeria, and the Philippines, bringing significant economic benefits to numerous charcoal producers.

Raw materials for charcoal briquette drying machine

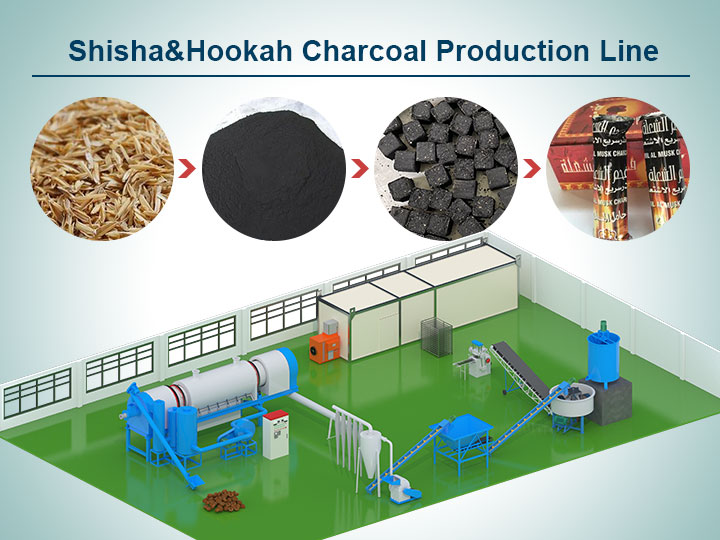

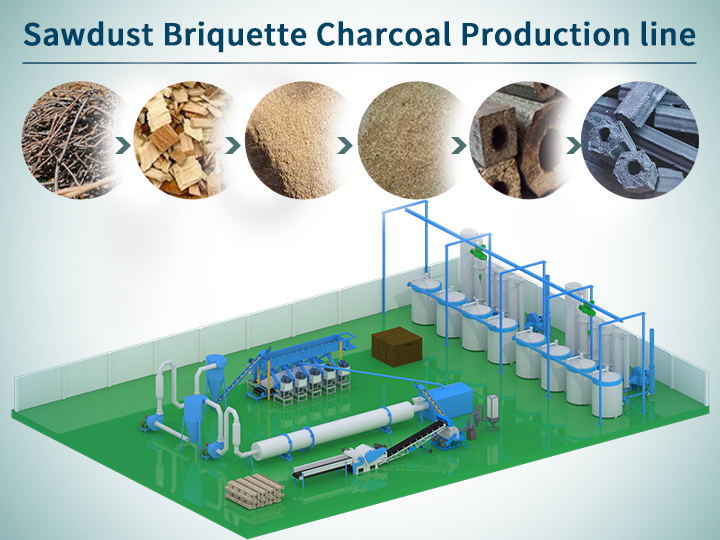

- Charcoal: shisha charcoal, barbecue charcoal, charcoal sticks, etc.

- Food: fruits, meat, herbs, plants, and other products that need to be dried or dehydrated.

- Multi-industry applications: suitable for almost all materials that need to be dried and dehumidified, with diverse functions.

Advantages of the box-type drying room

- High-quality materials: made from 304 stainless steel, it is moisture-resistant, corrosion-resistant, sturdy, and durable.

- Safe and reliable: electrical separation technology prevents risks such as electric leakage, fire, and explosion, ensuring operational safety.

- Even drying: the internal design has no dead corners, ensuring that materials are heated evenly and no part remains undried.

- Easy Installation: compact design allows for installation indoors or outdoors, offering flexible operation.

- Environmentally friendly and pollution-free: no open flames or smoke emissions, compliant with food-grade hygiene standards, making it a green and sustainable product.

- Highly intelligent: microcomputer-controlled intelligent system enables 24/7 continuous operation without manual supervision, automatically shutting down when the desired temperature is reached to save energy.

- Wide range of applications: not only suitable for charcoal, but also meets the drying needs of various industries such as food, herbs, and agricultural byproducts.

Structure of shisha charcoal dryer machine

Charcoal drying and dehumidifying unit (adjustable temperature in drying room: 20℃-75℃, adjustable humidity: 5%-95%)

With a trolley, the trolley is convenient for drying and short-distance transportation of dried charcoal.

The thermal insulation box is made of 4mm color steel for charcoal drying, and 7mm thermal insulation rock wool is sandwiched in the middle.

It can keep the outside of the charcoal briquette drying machine at room temperature, avoid burns, and at the same time ensure that the internal temperature of the machine does not rise.

Hot air circulation part. The hot air circulation system ensures that the hookah charcoal briquette drying machine heats evenly, allowing the edges and corners of the charcoal to dry as well.

The heating method of BBQ charcoal dryer

The box-type charcoal briquette drying machine supports multiple heating methods and can be flexibly customized according to customer requirements. Common heating methods include:

- Electric heating: clean and environmentally friendly, suitable for places with high environmental requirements.

- Gas heating: fast heating, moderate operating costs.

- Fuel heating: suitable for areas with convenient energy supply and sufficient heat.

- Coal heating: traditional method, suitable for some users with high cost requirements.

Based on the customer’s actual usage conditions, the manufacturer can provide personalized design and customization to ensure more convenient operation and energy-efficient performance.

How hookah charcoal dryer work?

After shaping, shisha charcoal or barbecue charcoal contains a high moisture content (approximately 40%) and requires drying to set its shape.

The box-type drying room features a fully enclosed structure and utilizes a hot air circulation system to evenly distribute heat throughout the chamber, thereby reducing drying time and ensuring consistent drying results. Under normal conditions, the moisture content of the material can be reduced from 40% to approximately 8% within 7–8 hours.

The operation process is simple:

- Place the charcoal blocks to be dried on the cart rack.

- Push the cart into the drying chamber.

- Set the drying time and temperature, then start the equipment.

- Once the set time is reached, the equipment automatically stops, and the dried and shaped charcoal blocks can be removed.

Video of charcoal briquette drying machine

Charcoal briquette drying machine models and parameters

| Model | Dimensions(mm) | Number of hot air fans(1 set/0.58KW) | Number of moisture extracting fans(1 set/0.12KW) | Induced draft fan(1 set/0.37KW) | Drying carts(group) | Amount of drying(each time/kg) |

| SL-2 | 4000*1600*2500 | 4 | 2 | 1 | 2 | 600 |

| SL-4 | 6000*1600*2500 | 4 | 2 | 1 | 4 | 1200 |

| SL-6 | 7200*2300*2500 | 6 | 2 | 1 | 6 | 1800 |

| SL-8 | 8800*2300*2500 | 6 | 2 | 1 | 8 | 2400 |

At present, Shuliy company has four charcoal drying box machines, the output of each drying is 600kg-2400kg. SL-2 is the smallest model machine, each drying 600kg; 2 means that this dryer has two trolleys. The size of the model in the table is named according to the number of trolleys; the largest dryer is SL-8, which can dry 2400kg each time, with 8 trolleys.

Conclusion

In summary, box-type drying rooms not only offer advantages such as energy efficiency, environmental friendliness, ease of operation, and wide applicability, but are also indispensable equipment in production lines for hookah charcoal and other products. They effectively ensure the shaping and quality of finished charcoal, helping manufacturers improve efficiency and profitability.

If you are considering building or expanding a charcoal production line, please click on the link above to access more professional solutions. Contact us immediately to obtain customized solutions and quotes—our team will provide you with comprehensive support!