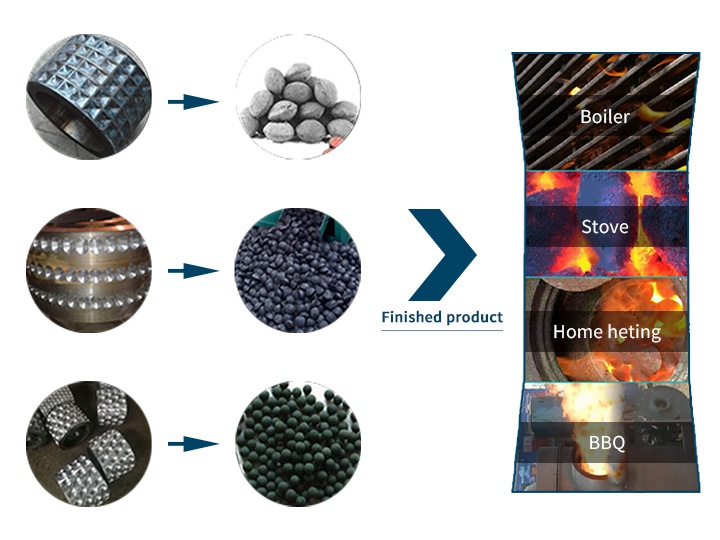

The barbecue coal ball briquette machine is a molding equipment that efficiently presses raw materials such as coal powder, charcoal powder, mineral powder, coke powder, biomass waste, etc. Through the 360° replaceable mold roller (±0.1mm precision rolling), the raw materials can be pressed into 12 customized ball shapes, such as round/elliptical/pillow.

The charcoal ball forming rate is ≥98%, the hardness exceeds 90kg/cm², and the combustion calorific value reaches 7500kcal/kg. It is widely used in metallurgy, chemical industry, electricity, energy, fuel processing and other industries.

Compared with traditional charcoal, the formed barbecue charcoal has the advantages of smokeless, non-toxic, odorless, high calorific value, easy to ignite, easy to transport and store, etc. It is an ideal fuel choice for energy saving and environmental protection.

Whether you are using it for the production of home barbecue charcoal or batch processing of industrial fuels. We provide a variety of models and mold shapes to meet the needs of different production and shape customization, helping you to efficiently carry out charcoal ball production business.

Coal ball briquette machine main structure

- Feeding part: it consists of hopper and screw feeding device, which is responsible for feeding the materials evenly and quantitatively between the pressure rollers. The screw feeder is driven by electromagnetic speed-regulating motor, which ensures stable material supply and guarantees the quality of ball formation.

- Transmission part: it includes motor, triangle belt, reducer, open gear and so on. The power is transmitted to the main shaft through the coupling, and then drive the slave shaft to synchronize the operation to realize the ball pressing action.

- Molding part: it consists of a pair of equal-sized pressure rollers with regularly arranged hemispherical mold holes on the surface. Equipped with hydraulic protection device, when encountered with hard objects or overload can automatically unload the pressure, to protect the pressure roller from damage.

This structural design ensures the high efficiency, stability, and safety of the coal ball briquette machine, which is the core guarantee for realizing high-quality barbecue charcoal molding.

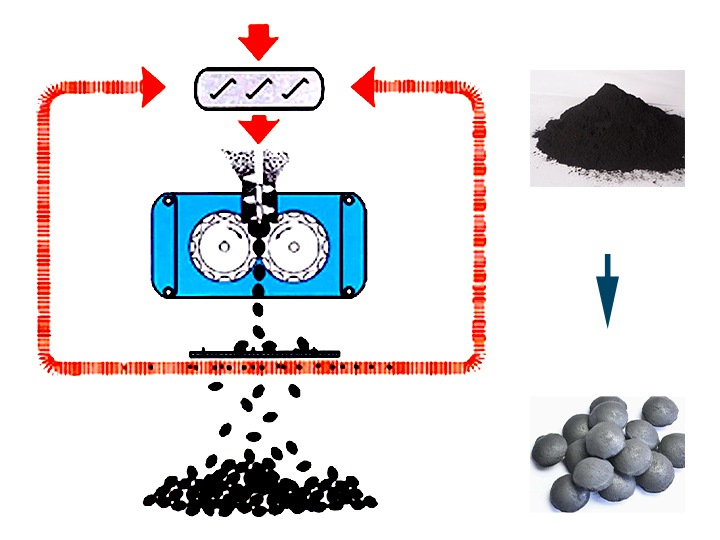

Working principle of charcoal press machine

The main part of the charcoal briquette machine is a pair of rotating shafts of the same size, with many hemispherical sockets of the same size and regularly arranged on the surface.

- The processed material will enter through the feed port and be squeezed into the hemispherical sockets on both sides under the action of its gravity and the pressure of the rollers on both sides.

- The hemispherical sockets on both sides merge into a complete sphere, and the raw materials inside will gradually be compressed, and finally form the coal ball briquette.

- With the further movement of the shaft, the formed coal ball falls from the discharge port.

Advantages of charcoal briquette-making machine

- Burn longer and save more coal: after pressing the coal powder into balls, it burns longer and more efficiently than ordinary coal.

- Environmental protection and energy saving: the briquettes pressed out do not smoke, have no odor, and have high heat, suitable for barbecue and heating, clean and energy-saving.

- Automatic protection equipment: there is a hydraulic protection device; if the machine contact with hard stuff, it can automatically unload, without damaging the pressure roller.

- Smoother feeding: specially designed feeding system can press even light powder (such as charcoal powder) into balls, not easy to block the material.

- Transmission system is more durable: the transmission device is closed, not easy to get into the ash, less noise, less wear and tear, longer use time.

- Pressing style can be customized: it can be made into round ball, pillow shape, egg shape and other shapes, and can also be customized in size and style according to customers’ requirements.

Raw materials requirements and charcoal briquette application

The charcoal ball briquette machine can be used to press coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, and coke powder. etc.

The fineness of the material should be below 3mm, and the moisture content should be 8-12%. Binder or other additives(e.g. desulfurized) should be prepared by users by coal type and the operating environment. The final products are widely used in refractory, power plant, metallurgy, chemical, energy, transportation, heating, and other industries.

Charcoal ball molding machine’s different molds

Depending on the shape and size of the BBQ charcoal balls that each person needs, we set up different molds to choose from, you can also tell us the finished product that you want, and we can customize it.

Display of BBQ coal ball briquette machine

Charcoal ball extruder machine technical parameters

The barbecue coal ball briquette machine demonstrates advanced technology and excellent performance, and its parameter information meets users’ needs in all aspects. Highly efficient production capacity and adjustable balling size provide it with excellent flexibility and production efficiency in the process of barbecue charcoal production.

| Model | Capacity | Power | Roll width | Roll diameter |

| SLYQJ-360 | 2t/h | 7.5kw | 250mm | 360mm |

| SLYQJ-400 | 4t/h | 11-15kw | 280mm | 400mm |

| SLYQJ-500 | 6t/h | 18.5-22kw | 300mm | 500mm |

| SLYQJ-650 | 10t/h | 20-30kw | 336mm | 650mm |

| SLYQJ-750 | 15t/h | 45kw | 400mm | 750mm |

| SLYQJ-850 | 25t/h | 75kw | 500mm | 850mm |

| SLYQJ-1250 | 35t/h | 130kw | 650mm | 1250mm |

Related video of coal ball briquette machine

Also, we have other coal-type machines to choose from, if interested, you can click: Hydraulic&Mechanical Hookah Charcoal Briquetting Machine and Honeycomb coal machine | Coal briquette-making machine.

To learn more about the excellent performance and technical advantages of the BBQ coal ball briquette machine, we encourage you to contact us actively. Our professional team will be happy to provide you with detailed product information, customized suggestions, and solutions. In addition, we warmly invite you to visit our factory to experience the efficient operation and advanced technology of BBQ charcoal balling machine.