Honeycomb coal machine is made from processed iron powder charcoal/raw coal (diameter <1mm), which is mixed and compressed to make coal briquette. The holes on the surface of the finished product make it easy to burn completely and reduce energy waste. After many improvements, our honeycomb charcoal briquette machine has the advantages of reasonable structure, high density of finished products, superior performance, and long service life.

Alternatively, you can choose from other types of charcoal briquette molding machines, including Charcoal briquette making machine | Charcoal briquette extruder, and Coal Ball Briquette Machine | BBQ Coal Press Machine.

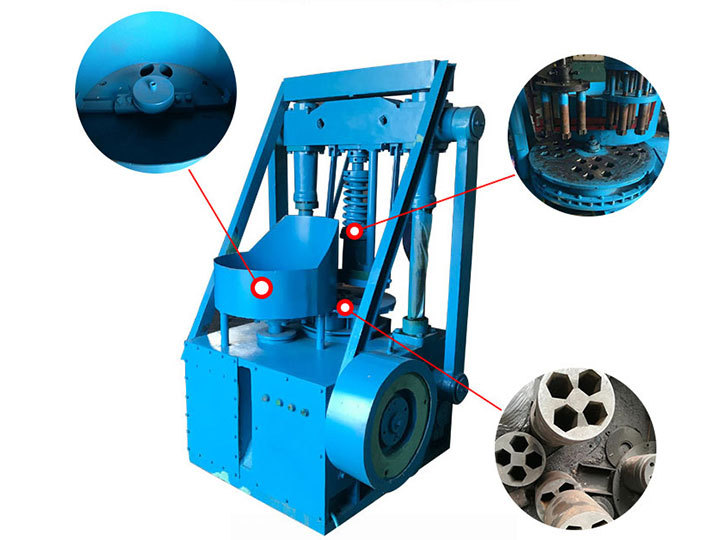

Structure and principle of honeycomb coal machine

The honeycomb coal machine has a simple structure and is divided into five parts: a body, a rotation, a feeding, a stamping, and a conveying. The parts work together and the operation is coordinated and stable.

- The body part: consists of a platen and a machine base, which are opened into the skeleton of the honeycomb coal machine.

- Transmission part: It consists of the motor, pulley, gear, drive shaft, and other components. The motor rotates the gear shaft through the pulley and transmits it to the transmission shaft through two gears. The pair of bevel gears and the rotating shaft drive the dial, and the dial is turned to move to the four-hole disc.

- Feeding part: It consists of a rotating shaft, a hopper, and a stirrer. It is driven by an axial gear to stir the coal and mix it into the mold.

- Stamping part: The stamping part mainly consists of four sliding rods, a sliding beam, a punching rod, a punching seat, a punching head, a movable pressing plate, a movable mold bottom, and a spring. When the machine rotates, the two gears rotate through the pull rod to drive the sliding beam. When the punch goes down, the punch is forced to move down, the movable plate moves up and the spring is tightened, the coal is pressed and the coal is punched, and the formed coal is loose, by the spring. Press the active plate to determine the compression of the coal.

- Conveying part: The conveying part is composed of a conveyor frame, a pulley, a bracket, and a conveyor belt. The conveyor belt is randomly rotated to send the shaped coal out of the body, and the adjustable screw on the conveyor can adjust the tightness of the conveyor belt.

The coal powder requirements for coal briquette machine

When the honeycomb coal machine is compressing coal powder, if the pulverized coal lumps are too large, we need to crush the coal first before pressing. At the same time, a certain amount of binder is usually added when using briquettes to press carbon powder, to achieve a better molding effect.

This is because when the moisture content of coal powder is high, it is not easy to form. And coal powder and charcoal powder must have proper binding properties, otherwise, the coal powder and charcoal powder must be processed. Ten to 20% of the caking coal can be mixed into the raw materials to enhance its binding properties.

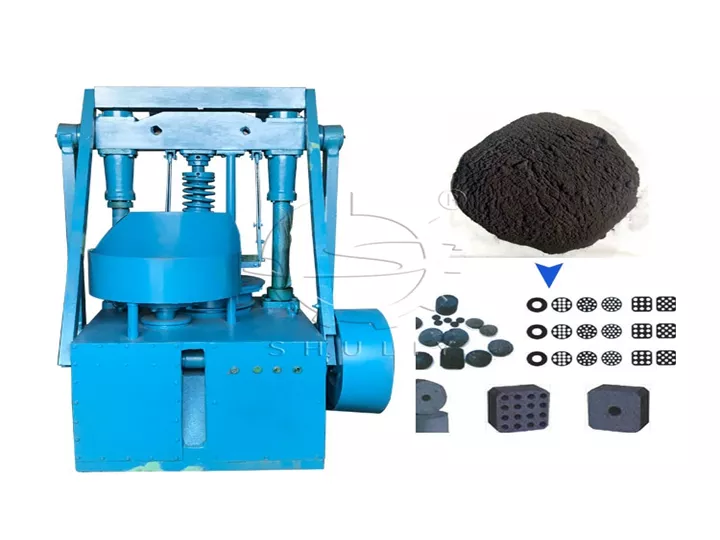

Molds for making charcoal briquettes with different shapes

To realize the multi-purpose function of one machine, we can replace the extrusion die of the briquette machine to make briquettes of different shapes. Usually, honeycomb coal briquettes are cylindrical with holes, and the number and diameter of the holes can be customized.

In addition, by changing different molds, the honeycomb coal machine can also produce quadrangular prisms with holes and hexagonal coal briquettes with holes. Of course, the number and diameter of the holes can also be customized.

Shape: Honeycomb coal powder briquette forming machine The Shape of a briquette can be round, cylindrical, square, rectangle, Polygon, Hexagon, fan, and so on many kinds, or you can have your ideal shape, we can help you to be your need.

Size: The final size according to the shape and machine mold, also can be decided within a certain range.

Features: Export briquetting with high density, flammable, long burning time, non-toxic, smoke-free, and other advantages.

Main features of the coal briquette-making machine

- The honeycomb coal machine works efficiently and the output is large.

- This machine has a small energy consumption and is environment-friendly.

- The mold is complete and can be exchanged easily.

- The coal briquettes produced by our honeycomb coal powder briquette molding machine have no chemical additives or smells and are smokeless, non-toxic, or combustible, so it is energy-saving environmentally protected coal molding equipment.

Parameter list of honeycomb coal briquetting machine

The honeycomb coal machine is a high-efficiency and advanced technology production equipment, the powerful pressure system and precision-designed molds ensure the uniform density and excellent quality of honeycomb coal. Its outstanding performance, reliability energy saving, and environmental protection bring reliable and advanced production solutions to the coal processing industry.

| Model | Power | Capacity | Weight |

| SL-120 | 4.5kw | 6000Pcs/hour | 1.4t |

| SL-140 | 7.5kw | 8000Pcs/hour | 1.5t |

| SL-160 | 11kw | 10800Pcs/hour | 2t |

| SL-220 | 11kw | 13500Pcs/hour | 3.8t |

Working video of coal briquettes-making machine

Thank you for your interest in our advanced honeycomb coal machine technology. If you are interested in our product display and eager to delve into more details, please do not hesitate to contact our professional team at any time. We will provide you with detailed information and answer your concerns to ensure you make a wise decision. Meanwhile, we sincerely invite you to visit our factory to provide you with a visual experience and let you have a more comprehensive understanding of our technical strength and product quality.