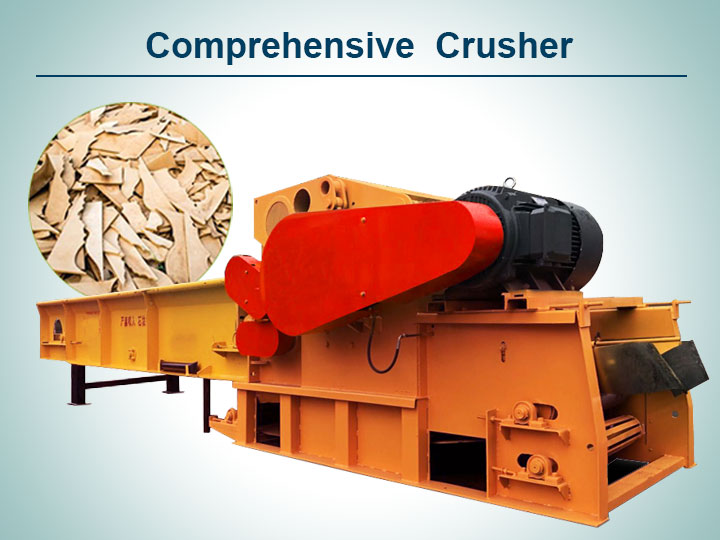

The comprehensive crusher machine can handle large-sized raw materials such as stumps, round logs, etc. It is custom-designed for complex recycled materials such as boards with nails, old furniture, and wooden pallets.

It employs a composite cutter and hydraulic pressure stabilization system to powerfully crush hardwood raw materials up to 800mm in diameter, yielding millimeter uniform crushed pieces.

The crushed product can be subsequently chipper process, and ultimately converted into biomass fuel, environmental protection boards and other high-value-added products, to help paper making, recycled wood industry to build zero-waste production.

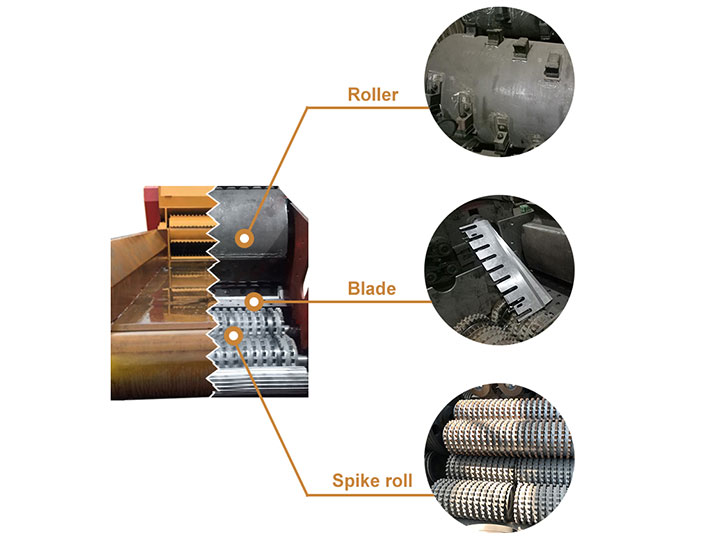

Structure of wood pallet composite crusher

The composite crusher consists of the following five parts: transmission, crushing, adjustment, screening and sorting, and coarse particle recycling and re-crushing.

- Transmission: In the front of the comprehensive crusher, there is a hydraulic system to help feed the material. This part is composed of the motor and the coupling and gear on it.

- Crushing: It is composed of a central cone on the main shaft and a guard cone outside. After the materials pass through the feeding rollers, there is a crushing roller waiting for them. We have two kinds of crushing rollers which choice depends on the materials you put.

- Adjustment: It consists of a centrifugal device at the bottom and outside of the main shaft adjustment device.

- Screening and sorting: This part consists of coarse and fine screens.

- Coarse particle recycling and re-crushing: It is a coarse-grain conveyor connected with a lifting cylinder on the lower side of the coarse screen. There is a lifter in the lifting cylinder and a feeder connected with a hopper on the upper part.

Details of industrial comprehensive crusher

We have two kinds of crush rollers: one called Tiger Claw Saw and the other called Knife Roll Saw.

- Tiger Claw Saw: The tiger claw saw effectively prevents the nails on the template and the pallet from affecting the equipment.

- Knife Roll Saw: The knife saw has a good crushing effect on wood with a relatively large logistics diameter, and it is also a good choice for the production of silage.

We also have two types of conveyor belts one is the leather belt and the other is the chain belt.

- Leather Belt: The leather belt suits some soft and sliced material, or if your requirement of products is not so much, you can also choose this leather one.

- Chain Belt: Different from the leather belt, this kind of chain belt is suited to transport every material including the boards with nails. And the chain one is harder and more wear-resistant than the leather one.

We have placed a magnetic roller behind the discharge conveyor belt. When the product mixed with nails is transported out of the discharge port, the magnetic roller will attract the nails, so that the nails are separated from the material. This device can help you save time and staff to separate nails and materials, and the separating nails can be sold or used in other ways as you like.

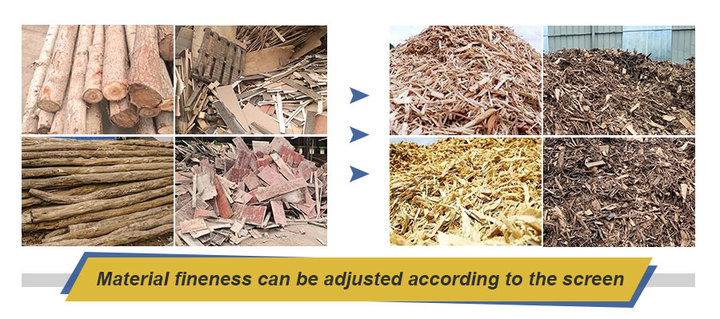

Working principle of the comprehensive shredder

When the hammer-type comprehensive crusher is working, the motor drives the rotor to rotate at a high speed, and the wood enters the comprehensive crushing chamber evenly.

The high-speed rotating hammer hits, cuts, and tears the wood, which causes the wood to be broken. At the same time, the gravity of the wood causes the wood to be broken. The high-speed rotating hammer rushes to the baffle and sieve bars in the frame. In the lower part of the rotor, a sieve plate is set.

The particles smaller than the sieve hole size in the crushed wood are discharged from the sieve plate. And the resistance of the wood is larger than the sieve hole size remains in the sieve. The board continues to be hammered and ground.

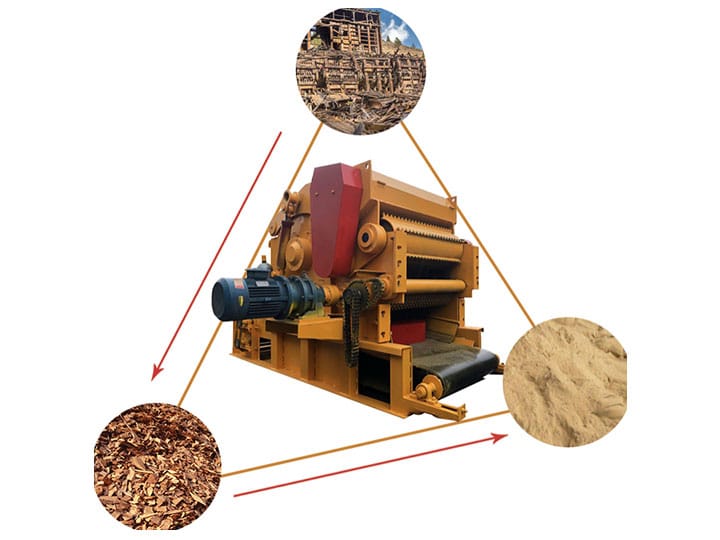

Raw materials for comprehensive crushing machine

This kind of comprehensive crusher is a full-function crushing machine. You can put everything you want here. Some large materials like furniture boards with nails and complex wooden pallets are also allowed to be put in. The same raw materials include waste packaging, templates, plates, branches, wooden bar boxes, trays, corn stalks, logs, and other waste wood materials and silage broken.

Main features of timber comprehensive crusher

- Adopt subgrade subgrade-free design, which can be used to test the installation and use of equipment under different geographical and topographic conditions.

- Adopt full automatic control, automatic feeding, and discharging, improve the production capacity, and make the man-machine separation, improve the safety factor of machine operation.

- Compared with traditional belt feeding, the feeding is smoother and the production capacity is greatly improved.

- Adopt the special small cutting tools independently developed by our factory, with a long service life and low maintenance cost.

- Equipped with a secondary discharging system, users can change the direction of discharging according to requirements and master the use flexibly.

- A comprehensive crusher is a wood-crushing machinery equipment, not afraid of the bamboo rubber board or goods pallet nails.

- The use of a hydraulic system, the hydraulic opening device for the shell opening and closing, can effectively reduce the maintenance labor intensity, improve the maintenance work efficiency, and shorten the maintenance work time.

- The monitoring system of the box crusher can monitor the operation status of the crusher at any time. The monitoring signal can be interlocked with the main control system to ensure the safe and reliable operation of the machine.

Precautions during installation of comprehensive crusher

- Pay attention to the verticality between the main body and the horizontal when installing the wood comprehensive crusher.

- The equipment should be installed on a level concrete foundation, and the crusher should be fixed with a foot.

- After installation, check whether the bolts in each part are loose and whether the door of the main engine is fastened, if so, please tighten it.

- Configure the power cord and control switch according to the power of the device.

- After checking the wood-integrated crusher, carry out a no-load test run, and the test run can start production.

Related video of large comprehensive grinder

If you are carrying out relatively small-scale crushing industrial processing, we also have the right machine, details can be found by clicking: Wood Hammer Mill Crusher | Large-yield Hammer Grinder.

If you have further questions about the performance and technical parameters of our comprehensive crusher machines or would like to experience the power of this highly efficient industrial equipment, please do not hesitate to contact our professional team. We are ready to provide you with detailed product information, and welcome you to visit our factory, looking forward to further communication with you and providing you with tailor-made solutions!