| Country | Vietnam | Date | September 5, 2021 |

| Production line | Sawdust briquette charcoal | Output | 8T/H |

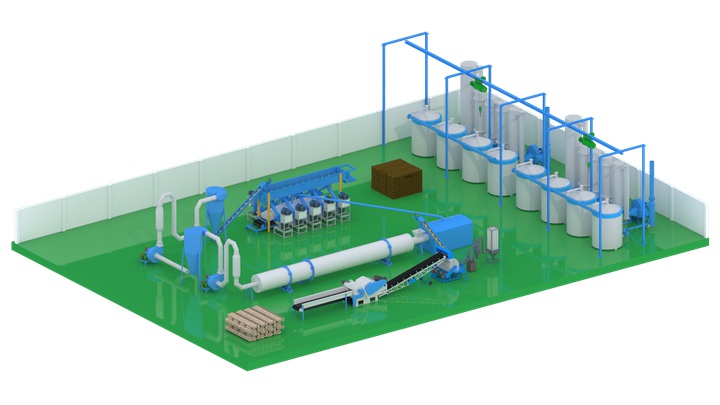

| Total power | 300KW | Project area | 18m*20m*30m(L*W*H) |

- The core equipment of the project: The sawdust briquette charcoal production line includes the wood crusher, totatry dryer, briquetting machine, carbonizing furnace and other auxiliary equipment.

- Customer’s main raw materials: Coconut husk, rice husk, peanut husk, crop straw and other wooden materials

- Whether to include packaging system (Y/N): Yes, automatic packaging system

- Whether it belongs to a customized plan (Y/N): Yes, a customized plan

- The scope of application of the project: Used to burn biomass briquette charcoal for heating

- Installation cycle of the project: 30 days

- Number of installation personnel: 5

- The production line operators: 3 people, this system adopts a semi-automatic production line, only one person is responsible for the normal operation of the machine, and two persons control the forklift and crane for carbonization.

- Problems in the installation process: A professional installation team can help customers install and solve problems during the installation process

- Whether the customer visits the factory (Y/N): Customers pay directly after inspecting the factory

- Our company provides various drawings:

1. Flow chart; 2. Installation drawing; 3. Pit drawing; 4. Operation instruction 5. Production construction drawing design drawing; 6. Steel structure complete drawing and steel list; 7. Workshop drawing plan And sectional drawings; 8. Steel structure construction drawings; 9. Detailed steel structure drawings and material list; 10. Floor drawings;

- One-stop after-sales service:

- We send two technical and installation engineers to guide the installation.

- After installation and adjustment, we have trained the customer’s workers how to operate.

- Train the workers how to maintain and protect.

- According to the function, we will formulate complete maintenance rules for you, including how to maintain, when to maintain, and Who maintains it.

- Our company’s after-sales department will call customers regularly to inquire about maintenance and provide suggestions. 6. In addition to wearing parts, our company provides one-year free warranty and permanent free technical support.