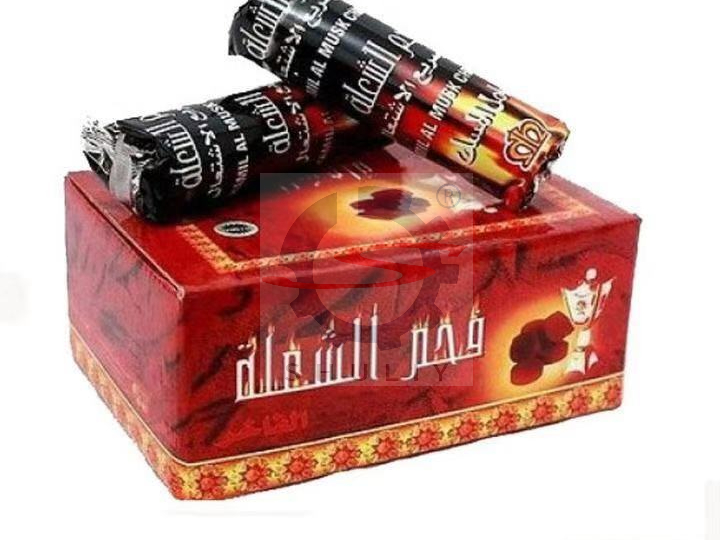

The shisha charcoal packing machine, also known as a pillow pouch packaging machine, is specifically designed for hookah (shisha) charcoal and other granular, sheet-like, or small-sized products such as cookies, candies, medications, and soap.

It can quickly and uniformly fill products into packaging bags while automatically measuring, sealing, and cutting them, making it an indispensable core piece of equipment for modern hookah charcoal production lines.

It is a very good choice for a fully automatic hookah carbon production line. This shisha charcoal packing machine has been exported to countries such as the Middle East, Ethiopia, Indonesia, and Malaysia, and has received widespread acclaim from customers for significantly improving product packaging efficiency and quality.

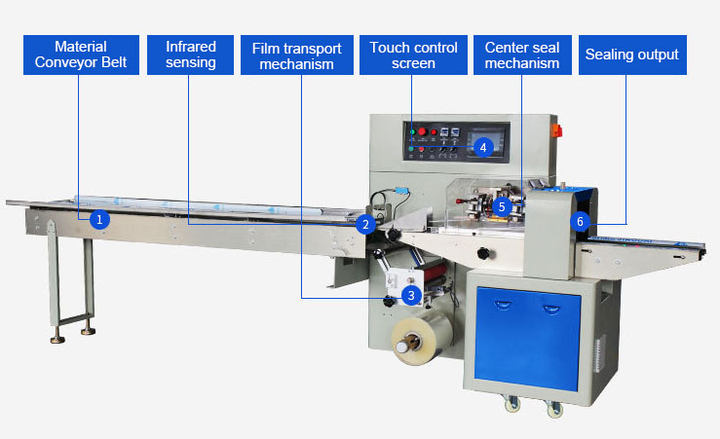

Shisha charcoal packing machine structure

The hookah carbon packaging machine includes a material conveyor belt to transport hookah carbon in an orderly manner to ensure that the quantity of each bag is consistent. Infrared induction is used for the precise cutting of packaging bags so that the cutting positions of packaging bags are the same.

The touch control screen can be used for the integrated setting of machine parameters, temperature settings, etc., which is convenient for operation, and automatically seals after the packaging is completed.

Benefits of packaging water smoke hookah charcoal

- Easy to transport: the compact size of the packaged hookah charcoal makes it easy to handle and store, reducing transportation costs.

- Moisture-proof and shatter-resistant: the packaging effectively prevents the water pipe charcoal from becoming damp or broken, ensuring the integrity of the product during transportation and storage.

- Enhances product quality: the elegant packaging gives the water pipe charcoal a more professional and refined appearance, improving the customer’s usage experience and satisfaction.

- Convenient for sales and distribution: standardized packaging facilitates retail and wholesale, supporting various specifications and quantities for repackaging needs.

Advantages of hookah charcoal bagging machine

- Smart touch control operation: equipped with a touch screen, packaging parameters can be easily set, enhancing operational convenience.

- Flexible length adjustment: the conveyor belt length can be customized, and the packaging bag length can be independently set to accommodate packaging requirements for products of various specifications.

- Precise temperature control: utilizes an independent PID temperature control system, suitable for various packaging bag materials, ensuring a secure and aesthetically pleasing seal.

- Efficient cutting design: the bag-cutting knife does not stick to the bag, reducing packaging film waste and improving production efficiency.

- Automated efficiency: fully automated operation, from metering to sealing and cutting, completed in one integrated process, saving labor and increasing output.

Hookah charcoal packaging machine detailed display

hookah carbon packaging machine control screen

With an intuitive user interface, it can accurately adjust packaging parameters and monitor production status, improving operational convenience and production efficiency.

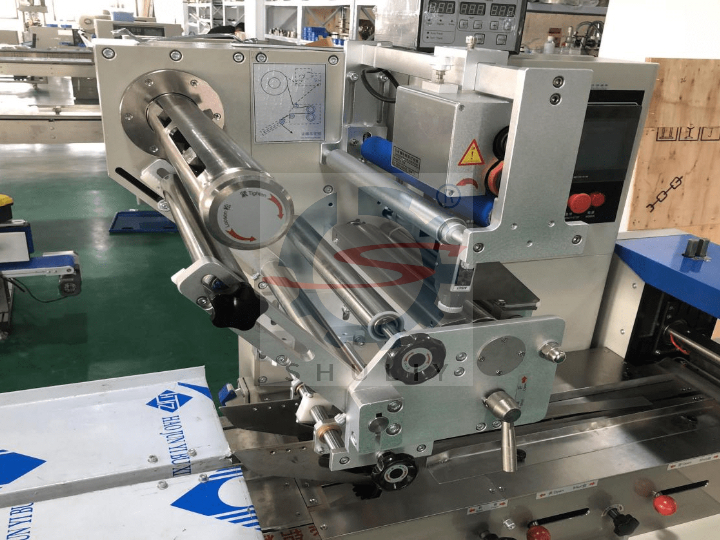

shisha charcoal packing machine conveyor

The product is conveyed to the working area of the wrapping machine by a feeding device and then wrapped in a continuous roll of packaging film.

packaging machine sealing

Once the product is placed in the bag, the other side of the bag will be closed while the space between the bags is sealed into individual packages. Next, the bags will be cut as needed to make each bag an individually sealed package.

hookah charcoal bagging machine glide track

Finally, the completed bag is removed from the discharge end of the packaging machine, usually using a conveyor belt or other device, for collection or further transport.

Shisha charcoal packing machine parameters

| Model | SL-250 | SL-350 | SL-450 | SL-600 |

| Bag Length | 100-600mm | 100-600mm | 100-600mm | 120-600mm |

| Bag width | 50-110mm | 50-160mm | 50-210mm | 50-280mm |

| Bag height | Max 40mm | Max 100mm | Max 100mm | Max 100mm |

| Packing speed | 5-200 bags/min | 5-200 bags/min | 5-200 bags/min | 30-180 bags/min |

| Power | 220V, 50/60Hz, 2.4KVA | 220V, 50/60Hz, 2.4KVA | 220V, 50/60Hz, 2.6KVA | 220V, 50/60hz, 3.6KVA |

| Weight | 800kg | 800kg | 900kg | 960kg |

Optional hookah charcoal dispenser

This part can automatically group the hookah charcoal, generally 10 in a group, that is 10 round hookah charcoal as a small bag, 10 bags into a box. Quantity customization is also possible. The hookah carbon dispenser can reduce the number of employees, automate the whole packaging process, and improve packaging efficiency.

Automatic hookah charcoal bagging machine packaging process

- The dispenser is put into the conveyor belt or manually into the groove

- Set the parameters

- Temperature setting

- Packing film pulling

- Bag forming

- Bag closure

- Packaging is complete

Video of hookah charcoal packaging machine

Our shisha charcoal packing machine will undoubtedly be your right hand in your business when you are looking for the best packaging solution for hookah charcoal. If you have any questions about the machine, please feel free to contact us, we look forward to working with you to create a new era in the field of coal production packaging.