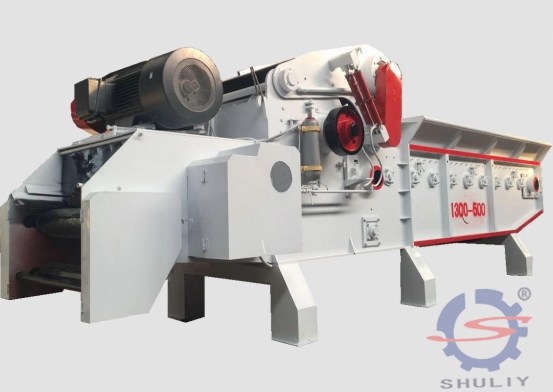

In order to improve product quality, Shuliy Factory has developed a new batch of drum-type slicing machine. Shuliy Machinery Manufacturing Co., Ltd. is a professional material reusing equipment. In order to solve the problem that some large materials cannot be broken during production, This year, our company began to specialize in the production of drum chippers, wood shredders, used template crushers, and other crushers. Today, let’s talk about drum chippers.

Product description:

The main raw materials for cutting the new drum chipper are small-diameter wood, wood harvesting, processing residues (such as branches, branches, boards, slats, round cores, waste veneers, waste wood, etc.), and can also be used for cutting non-cutting Wood raw materials (such as sugar cane, reeds, bamboo, etc.).

After cutting the raw materials, it becomes a small piece of wood with certain specifications. As particleboard, medium density board, wood fiberboard, paper making, power plant, boiler and other industries, this product has advanced structure, high slicing quality, wide adaptability of raw materials and convenient operation and maintenance.

Performance characteristics:

When the new drum chipper is working, the motor drives the rotor to rotate at a high speed, and the wood evenly enters into the cavity of the integrated crusher. The hammerhead impacts at high speed, the wood is broken by shearing and tearing wood, and the gravity of the colleague makes the wood.

From the high-speed rotating hammerhead to the body baffle, the screen strip, in the lower part of the rotor, is provided with a sieve plate, and the garbage in the crushed wood smaller than the mesh size is discharged through the sieve plate, and the wood larger than the mesh size is retained in the sieve plate Continued to be hit and ground by a hammer.

The main body of the chipper dust collector is a box body, and the lower part of the box body is provided with a gray door, and the box body is installed in a vertical frame. The vertical frame is covered with a filter bag, and the dust remover receives dusty gas from the centrifugal separator. It enters the box from the entrance of the box and is discharged into the outside space through the filter bag.

Due to the dust removal efficiency of the filter bag dust collector can reach more than 97%. Therefore, there is no pollution in the working environment. When the filter resistance of the precipitator rises, you can choose to stop at this time and manually clean it during the rest time. When cleaning the dust collection of the filter bag, the filter bag can be shaken for more than ten seconds, so that the dust stuck on the inner surface of the filter bag can be shaken off, and the shaken dust can be directly discharged into the dust bag through the box gray door, and then Clear. Green and environmentally friendly, no pollution.

Working principle:

The new drum type chipper is provided with a vehicle body of a traveling device, and is provided on a one end side of the vehicle body to rotate the wood to form a wood-type rotary crushing device, and a wing type supply provided at an upper portion of the rotary crushing device The device is disposed in the rotary crushing device and carried out by the unloading device that removes the wood that has been broken by the rotary crushing device and is discharged to the outside from the lower portion of the rotary crushing device to the other end side of the traveling direction of the vehicle body. A driving device for driving the device between the devices, a rotary crushing device, a blade feeding device, and a driving source of the carrying device.