With the continuous growth in logistics, transportation, and increasing demands for eco-friendly packaging, the wood pallet block making machine is becoming an increasingly vital piece of equipment in pallet production and wood recycling. This machine uses waste wood materials such as wood chips and sawdust as raw materials, forming wood pallet blocks through high-temperature and high-pressure molding. It helps enterprises achieve cost reduction, efficiency improvement, and resource recycling.

Core equipment for pallet and logistics industries

In warehousing and logistics, wooden pallets serve as the most fundamental and widely used handling tools. Pallet blocks produced by wood block machines feature uniform dimensions and consistent strength, meeting the load-bearing and specification requirements for export pallets.

Taking common equipment as an example, a single wood block machine can produce 3,000–6,000 blocks daily, supporting annual pallet production of hundreds of thousands. They are widely used in port logistics, e-commerce warehousing, and freight companies.

Wood processing and waste recycling industry

Sawmills, furniture factories, and wood product processing enterprises generate substantial amounts of sawdust and wood chips daily. Wood block machines directly convert this waste into high-value pallet blocks, achieving over 95% material utilization.

Compared to selling waste wood directly, processed block products command market prices 2–3 times higher, significantly boosting overall corporate profitability.

Export packaging and international trade industry

Export wooden pallets face stringent environmental and standardization requirements, particularly in European and American markets.

Wood pallet block making machines produce high-density, deformation-resistant blocks compliant with fumigation or fumigation-free packaging standards. They are widely used in packaging machinery, building materials, and home appliances for export.

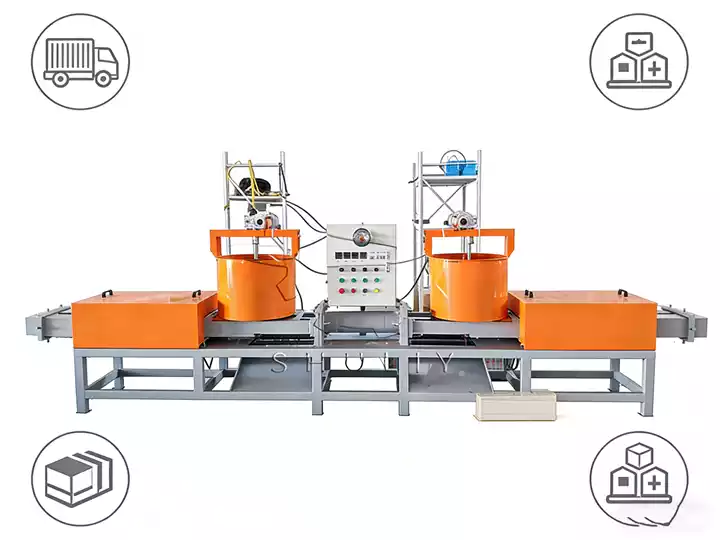

Low-investment solution for business

Wood block machines feature high automation, compact footprints, and require only 1–2 operators, making them ideal for small-to-medium enterprises or startup factories.

Basic models operate at 15–22kW, offering low energy consumption and simple maintenance—a practical choice for pallet processing and supplementary income streams.

Wood pallet block making machines continue to deliver sustained value across diverse sectors. For inquiries, please contact us anytime.