목재 팔레트 블록 기계는 모듈형 열압 성형 시스템을 통해 나무 칩, 깎은 나무 조각 및 기타 폐기물을 표준 또는 맞춤형 크기의 패드(밀도 550-1000kg/m³)로 가공할 수 있습니다.

이 기계는 훈증 없는 인증을 받았으며, 48시간 방수 및 균열 저항 특성을 가지고 있으며, 지능형 CNC 금형이 장착되어 있습니다(75-145mm의 전체 크기 맞춤 지원). 이 기계는 건축 충격 흡수 기초, 물류 팔레트 받침대, 정밀 장비 포장 지원 등 20개 이상의 응용 시나리오에 적합합니다.

이 장비는 조작하기 쉽고, 한 사람이 동시에 여러 장비를 관리할 수 있습니다. 단일 팔레트 블록 기계는 하루에 4-5m³의 초과 가공 능력(연간 1500톤의 폐목재 가공 가능)을 달성할 수 있으며, 모든 종류의 기업의 배치 생산에 적합합니다.

우드 톱밥 팔레트 블록 기계의 장점

- 원자재의 강한 적응성: 다양한 유형, 형태 및 크기의 원자재를 처리하여 다양한 고객의 요구를 충족할 수 있습니다.

- 높은 자동화 수준: 자동화된 생산 과정은 수작업의 강도를 줄이고 작업 환경을 개선합니다.

- 유연한 금형 교체: 금형과 매개변수를 신속하게 조정하여 다양한 사양의 패드 생산에 적응할 수 있습니다.

- 강한 생산 유연성: 다양한 크기와 유형의 맞춤형 완제품이 여러 산업에 적용될 수 있습니다.

- 무훈증 처리: 제품은 고온에서 압출 및 성형되어 훈증이 필요 없으며, 수출 기준을 충족합니다.

원자재 및 완제품의 특성화

목재 팔레트 블록 기계의 핵심 원자재는 3-5mm 목재 조각으로, 주로 다음 두 가지 유형의 가공에서 나옵니다:

- 목재 가공 폐기물: 톱밥(가공된) 및 가구 공장과 목재 팔레트 생산에서 나오는 가장자리를 포함합니다. 목재 분쇄기\/해머 밀), 나무 조각 (생산된) 나무 쉐이버 기계농업 바이오매스: 쌀 껍질, 목재 칩 및 기타 보조 재료와 혼합할 수 있으며, 친환경 접착제를 10%-15% 추가합니다.

- 농업 바이오매스: 쌀겨, 나무 조각 및 기타 보조 재료와 혼합할 수 있으며, 환경 친화적인 접착제를 10%-15% 추가합니다.

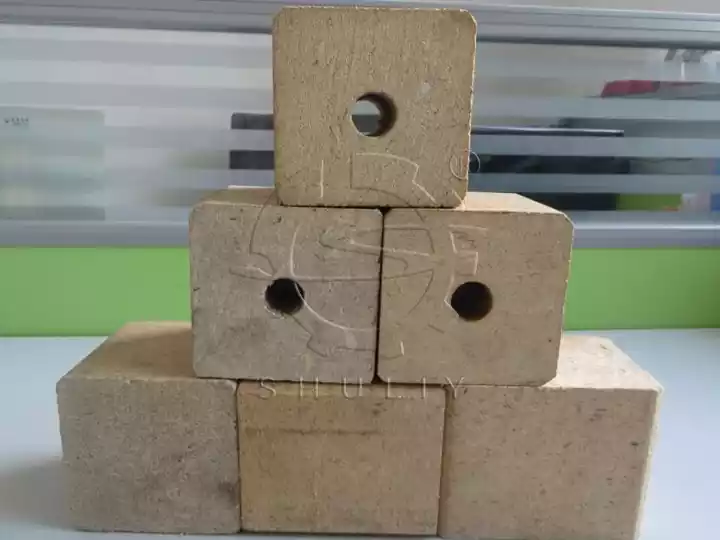

완성된 블록은 고형 타입과 중공 타입으로 나뉩니다. 몰드를 전환함으로써 75-145mm의 전체 크기 맞춤화를 지원할 수 있습니다(예: 80×80mm 표준 타입, 120×140mm 형태 블록).

목재 톱밥 블록 압축 기계 작동 원리

원자재 전처리

- 선별 및 분쇄: 원자재(우드 칩, 톱밥, 쌀 껍질 등)는 분쇄기를 통해 3-5mm 입자 크기로 가공해야 하며, 3단계 선별을 통해 불순물을 제거해야 합니다.

- 건조 및 습도 조절: 원자재의 수분 함량은 건조기를 통해 12% 미만으로 줄여 접착제가 효과적으로 침투하고 경화될 수 있도록 합니다.

- 접착제 혼합 및 블렌딩: 원자재의 덩어리짐을 방지하고 밀도 균일성을 개선하기 위해 혼합 장치에 접착제를 10%-15% 비율로 고르게 적용합니다.

열압 성형

- 유압 구동: 유압 실린더는 50-100MPa의 고압을 적용하여 피스톤을 구동하고 혼합물을 금형으로 밀어 넣어 밀도 550-1000kg/m³의 연속 스트립을 형성합니다.

- 고온 경화: 금형에는 내장된 전기 히팅판(120-180℃)이 있어 접착제의 경화를 가속화하고 블록의 내부 결합 강도(≥1.07MPa) 및 균열 저항(48시간 물에 담가도 균열 없음)을 향상시킵니다.

- 금형 적응: 75×75mm에서 140×145mm의 전체 크기 맞춤 지원, 금형 교체를 통해 고형/중공, 구멍 있음/구멍 없음 및 기타 구조 전환을 달성합니다.

절단 및 냉각

- 고정 길이로 절단: 열 압착 성형 후 긴 스트립은 자동 절단기로 1.2m 표준 세그먼트로 절단되며, 절단 오차는 ≤±1mm입니다.

- 자연 냉각: 절단된 반제품은 내부 응력을 제거하고 치수 안정성을 보장하기 위해 24시간 동안 통풍이 잘 되는 환경에서 냉각됩니다.

마감 및 슬리팅

- 정밀 절단: 냉각 후, 긴 스트립은 CNC 절단 기계에 의해 두 번 가공되어 최종 사양 패드(예: 80×80mm, 100×100mm 등)가 생산됩니다.

- 분할 블록 선택 사항: 가구 제조, 정밀 포장 및 기타 시나리오에 적합한 소형 블록(예: 30 × 30mm)으로의 주문형 슬리팅 지원, 시간당 최대 1,800 블록의 생산 효율성.

목재 블록 제작 기계의 매개변수

배출 구멍의 수와 크기는 특정 생산 요구 사항을 충족하도록 맞춤 설정할 수 있습니다.

| 모델 | SL-WB100 |

| 총 전력 | 15kw |

| 용량 | 4-5 m3/24h |

| 블록 밀도 | 550-600kg/m3 |

| 치수 | 4800*760*1300mm |

| 무게 | 1200kg |

우리의 목재 팔레트 블록 기계를 선택해 주셔서 감사합니다. 고형 블록이나 천공된 블록을 생산하고 싶으시다면, 다양한 산업의 요구에 맞게 맞춤 제작할 수 있습니다. 간편한 조작과 높은 생산 효율성을 갖춘 이 기계는 폐목재 자원의 재활용을 실현하는 데 이상적입니다. 자세한 프로그램과 유리한 견적을 원하시면 지금 바로 문의해 주세요!