El horno de carbonización continuo es un equipo de carbonización que ahorra energía, diseñado para la producción a gran escala de carbón de biomasa. Tiene una capacidad de operación ininterrumpida de 24 horas, puede realizar alimentación y descarga constantes, y la producción puede alcanzar de 800 a 1000 kg/h.

El equipo genera productos de carbón de alta calidad mediante la carbonización de astillas de madera, cáscaras de cacahuete, cascarillas de arroz, paja y otros materiales de biomasa a altas temperaturas. Los gases combustibles (por ejemplo, monóxido de carbono, metano, hidrógeno) generados durante el proceso de carbonización pueden ser calentados mediante combustión cíclica. Esto reduce en gran medida el consumo de energía y disminuye la contaminación ambiental, lo que lo convierte en una opción ideal para los procesos de producción de carbón modernos y respetuosos con el medio ambiente.

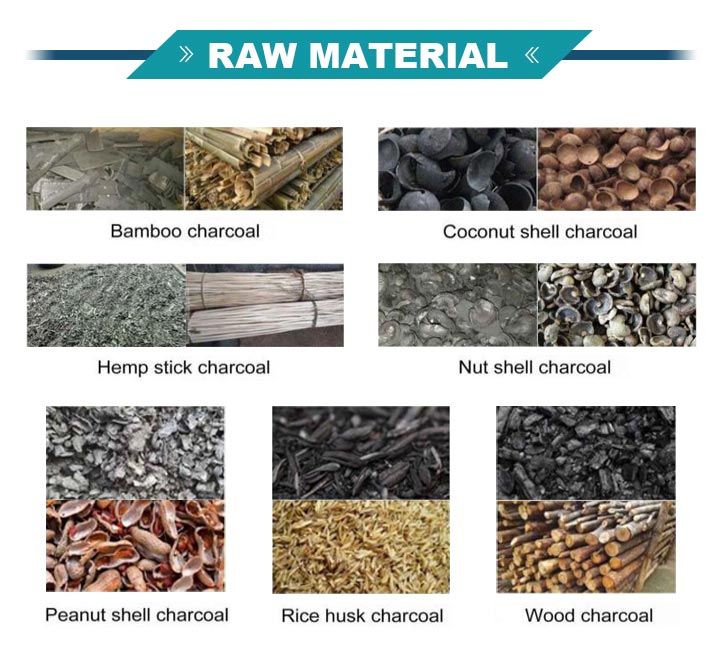

Materias primas del horno de carbonización de carbón vegetal

El horno de carbón continuo es adecuado para una amplia gama de materias primas de biomasa con una estructura carbonosa, incluyendo pero no limitado a:

- Astillas de madera, aserrín, ramas de árboles, trozos de madera, cortezas de árboles.

- Residuos agrícolas: cáscaras de cacahuete, cascarillas de arroz, tallos de maíz, tallos de cáñamo, tallos de algodón.

- Materiales de cáscara: cáscaras de coco, cáscaras de nuez, cáscaras de palma.

- Otros residuos orgánicos: residuos de hierbas, residuos de frutas y verduras, fibras vegetales, etc.

La adaptabilidad diversificada de las materias primas permite a los usuarios elegir de manera flexible según los recursos locales, mejorando efectivamente la tasa de utilización de las materias primas.

Características de los productos terminados y perspectivas de aplicación

Después de la carbonización continua, el carbón de biomasa muestra un color negro, alta densidad, alto poder calorífico, combustión estable, sin humo y menos cenizas, y se utiliza ampliamente en los siguientes campos:

- Suministro de energía: reemplazando el carbón tradicional, utilizado para calefacción doméstica, carbón para barbacoa, combustible para calderas industriales.

- Uso agrícola: acondicionador de suelo, fertilizante de biochar, mejora de la fertilidad del suelo y retención de agua.

- Uso industrial: utilizado en desulfuración metalúrgica, procesamiento de carbón activado y otros campos de procesamiento profundo.

- Uso ambiental: como adsorbente para tratar aguas residuales y gases de desecho, reducir las emisiones de carbono.

Diferentes escenarios de aplicación tienen diferentes requisitos para los productos de carbón, y los clientes pueden llevar a cabo un tratamiento posterior o un procesamiento profundo de los productos terminados según sus necesidades.

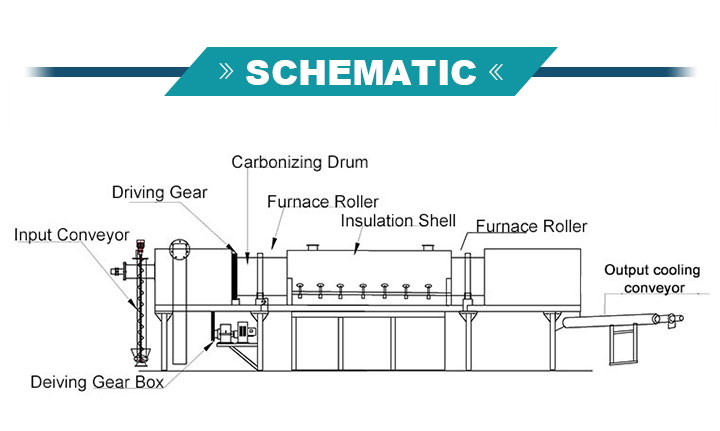

Estructura del horno de carbonización de carbón vegetal rotativo

Horno de carbonización continuo como un conjunto de equipos de carbonización integrados, inteligentes y eficientes. Principalmente consta de las siguientes partes clave, y cada módulo opera de manera sinérgica para garantizar el funcionamiento eficiente y ahorrador de energía del equipo:

- Gasificador: utilizado para el precalentamiento inicial del equipo, que se puede apagar más tarde para ahorrar energía.

- Gasificador: para el precalentamiento inicial del equipo, que se puede apagar en una etapa posterior para ahorrar energía. Cuerpo del carbonizador: adoptando un diseño rotativo para lograr una carbonización continua y uniforme.

- Transportador de tornillo: alimentación continua para asegurar un proceso de carbonización ininterrumpido.

- Sistema de purificación de gases de combustión: reciclar y purificar el gas combustible para realizar calefacción en circuito.

- Sistema de tiro inducido: enviar el gas purificado a la cámara de combustión para calefacción continua.

- Dispositivo de descarga por enfriamiento: enfría rápidamente los productos de carbón para facilitar su almacenamiento.

- Bin de almacenamiento: recoger el carbón enfriado para su uso posterior.

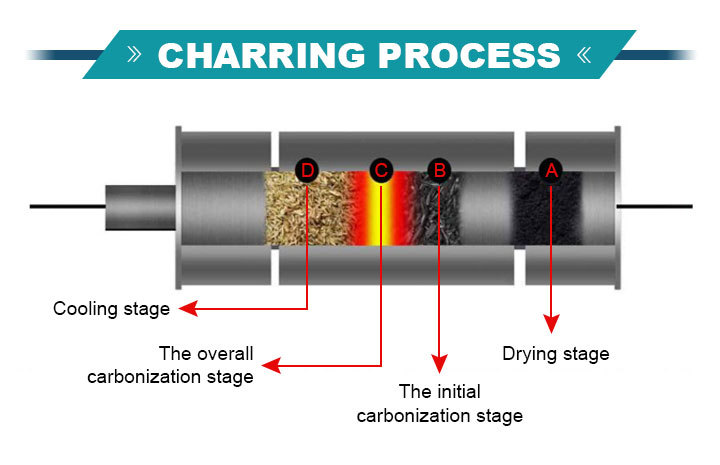

Principio de funcionamiento del horno de carbonización continua

El proceso de carbonización de materiales en el horno de carbonización continua se divide principalmente en la etapa de secado, la etapa inicial de carbonización, la etapa de carbonización completa y la etapa de enfriamiento.

Etapa de secado

- Calentado por la ignición del gasificador, la temperatura del horno aumenta.

- La humedad en el material comienza a evaporarse, dependiendo de una fuente de calor externa.

- No se ha producido ninguna reacción química significativa en el material en esta etapa.

Etapa inicial de carbonización

- El material comienza a descomponerse lentamente y libera una pequeña cantidad de energía térmica.

- La temperatura necesaria para la carbonización se alcanza gradualmente y la estructura química interna comienza a cambiar.

- Algunos de los componentes inestables comienzan a descomponerse.

Etapa de carbonización completa

- La pirólisis rápida del material produce una gran cantidad de subproductos líquidos como alquitran de madera, ácido acético y metanol.

- Al mismo tiempo, se liberan gases combustibles como metano y etileno.

- Estos gases se queman en el horno para generar un alto calor, lo que promueve aún más la carbonización y eventualmente produce carbón.

Etapa de enfriamiento

- El material después de que se completa la carbonización necesita ser enfriado de forma natural o forzada.

- Después de enfriarse, puede almacenarse de forma segura para evitar la combustión espontánea al contacto con el aire.

Ventaja del horno de carbonización continua

- Operación continua, alto grado de automatización: puede realizar 24 horas de operación ininterrumpida, mejorando enormemente la eficiencia de producción y ahorrando costos laborales.

- Rendimiento ambiental superior: equipado con recuperación de gases de combustión, dispositivos de combustión y eliminación de polvo para garantizar que las emisiones de escape cumplan con los estándares, protección ambiental y sin contaminación.

- Sistema de enfriamiento de alta eficiencia: enfriamiento por agua en espiral + diseño de enfriamiento por bobina, enfriamiento rápido, seguro y eficiente, mientras se ahorra espacio.

- Sistema de alimentación inteligente: todo el conjunto de equipos está equipado con un elevador de cubos para realizar una alimentación automática, ahorrando tiempo y mano de obra.

- Excelente efecto de carbonización: para aserrín y otras partículas finas de materias primas, no es fácil acumular el problema de la carbonización incompleta, la estructura del horno rotatorio puede lograr una carbonización completa y uniforme.

- Calentamiento uniforme, transferencia de calor rápida: la estructura rotativa del cuerpo del horno hace que los materiales reciban calor de manera uniforme y la carbonización sea más completa. La capacidad de procesamiento es de hasta 3-5 toneladas por hora, y la eficiencia es de 10-20 veces la del horno de carbonización estático tradicional.

Parámetros técnicos del horno rotatorio de carbonización de carbón

| Tipo | SL-1200 |

| Dimensión | 11.5*2*1.9m |

| Capacidad | 2000kg/h |

| Potencia Total | 25kw |

| Tamaño de entrada | Menos de 10cm |

| Relación de carbonización para cáscaras de coco | 3:1 (3 t de cáscaras de coco: 1 t de carbón) |

| Temperatura de carbonización | 600-800℃ |

Nueva máquina de carbonización continua horizontal

Este innovador equipo de alta eficiencia en carbonización integra alimentación y descarga continuas, utilizando calefacción externa combinada con tecnología de gases combustibles de circulación propia para lograr una producción de carbonización estable, eficiente y respetuosa con el medio ambiente.

En comparación con los métodos tradicionales de carbonización vertical, la nueva estructura de tambor rotatorio horizontal garantiza una carbonización más uniforme, mayor rendimiento y menor consumo de energía, además de reducir significativamente las emisiones de gases de combustión, ofreciendo ahorros energéticos reales y protección ambiental.

Amplio rango de materias primas aplicables

Este equipo es adecuado para diversas materias primas de biomasa, incluyendo cáscaras de cacahuete, aserrín, virutas de bambú, cáscaras de arroz, tallos de maíz, bagazo de caña de azúcar, cáscaras de coco, posos de café, ramas, paja, residuos medicinales y lodos.

Materiales con tamaños de partícula entre 1–20 mm y contenido de humedad <15% pueden ser alimentados directamente en el horno de carbonización. Los materiales que superen los 20 mm requieren pretrituración, mientras que los que tengan más del 20% de humedad deben secarse previamente para garantizar la eficiencia de la carbonización y la calidad del producto. Algunos materiales inflamables o explosivos no son adecuados para su procesamiento en este equipo.

Diseño estructural del equipo

El horno de carbonización continua consta principalmente de un tambor de carbonización principal, cabezales de alimentación/descarga, cámara de combustión, quemador, cámara de aislamiento, dispositivo de alimentación, máquina de descarga y enfriamiento, ventilador de suministro de oxígeno, ventilador de tiro inducido y sistema de control eléctrico.

La unidad principal emplea un cilindro horizontal con un diámetro de 800–2000 mm y una longitud de 8–18 m, personalizable según los requisitos del usuario. La rotación continua asegura una calefacción uniforme de los materiales mientras elimina eficazmente los problemas de calefacción desigual y baja eficiencia comunes en los carbonizadores tradicionales.

Principio de funcionamiento de la carbonización

Al arrancar, el quemador o el precalentador de combustible de madera precalienta el tambor principal a 400–600°C. Una vez alcanzada la temperatura, comienza la alimentación continua. Los materiales avanzan lentamente a través del tambor, sometiéndose sucesivamente a secado, pirólisis y carbonización.

Durante la carbonización, se liberan gases combustibles como CO, H₂ y CH₄. Estos gases son aspirados al horno por un ventilador de tiro inducido para una combustión secundaria, creando una fuente de calor secundaria estable. Una vez que se genera suficiente gas combustible, el quemador de precalentamiento puede apagarse gradualmente, permitiendo la autosuficiencia energética en el proceso de carbonización y reduciendo significativamente el consumo de energía.

Video relacionado sobre el horno de carbonización continua

No solo eso, también ofrecemos una amplia gama de modelos y tipos de hornos de carbonización de carbón vegetal. Cubriendo una gama de hornos de carbón vegetal de tipo elevador, hornos de carbón vegetal horizontales y pequeñas máquinas de carbón vegetal, para satisfacer diferentes escalas y demandas de materias primas. (Publicación relacionada: Horno de carbonización de carbón vegetal | Máquina para fabricar carbón vegetal de biomasa) ¡Bienvenido a contactarnos para obtener más detalles del producto y una cotización!