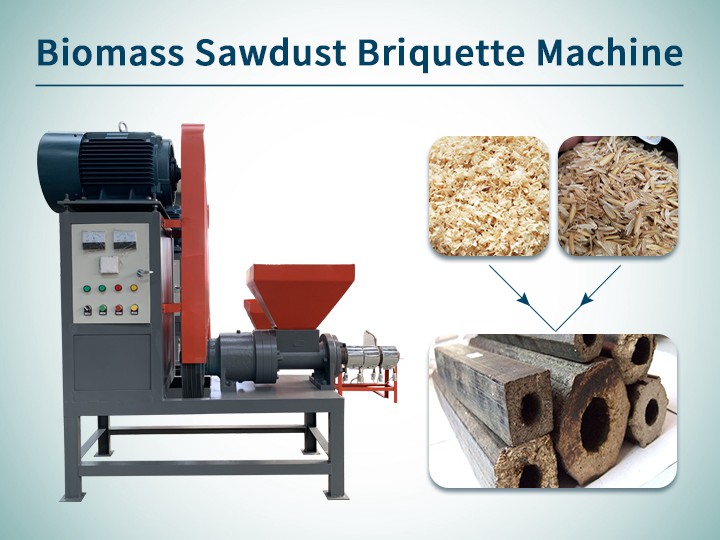

バイオマス木くずブリケット機は、高温・高圧のバインダーなし成形技術を採用しています。木くず、削りくず、稲わら、ピーナッツの殻、バガスなどの農業および林業の廃棄物を、密度1.0-1.4g/cm³の中空棒バイオマス燃料に圧縮することができます。

普通の木材と比較して、木くずブリケットは点火が容易で、熱量が20%以上増加し、汚染が少なく、密度が高いです。保存、輸送、長時間の燃焼が容易で、農業や林業の廃棄物に対する経済的で実用的なクリーンエネルギーソリューションを提供します。

バイオマスブリケットの原材料と用途

バイオマス燃料木くずブリケット機は、主にリグニンを含む多くの農業および林業廃棄物に適しています。主なものは次のとおりです:

- 木材チップ、竹チップ、削りくず

- 稲わら、ピーナッツの殻、トウモロコシの芯

- 綿の茎、作物の茎、果樹園や庭の剪定枝

- バガス、ココナッツの殻、家具工場、竹製品工場、箸工場の端材など。

原材料要求:粒度≤5mm;含水量≤12%。(可使用木材粉碎机和滚筒烘干机进行预处理)

木材おがくずブリケット押出機の完成品

木くずブリケット機で作られたバイオマス燃料ロッドは、多くの分野で広く使用されています:

- 民間の暖房燃料:家庭用暖炉や暖房ストーブの燃料として直接使用でき、特にヨーロッパやアメリカで広く使用されています。

- 工業生産の原材料:家具製造や木工製品などの工業加工に適しています。

- クリエイティブおよび手工芸:木の棒の一部は、手工芸、クリエイティブな生産、その他の特別な分野で使用できます。

- 農業利用:燃焼後の灰はリン肥料として使用でき、資源の再利用を促進します。

- 便利な保管と輸送:完成品は高密度で体積が小さく、パッケージング(シュリンク包装)が簡単で、保管と輸送が便利で、コストを削減します。

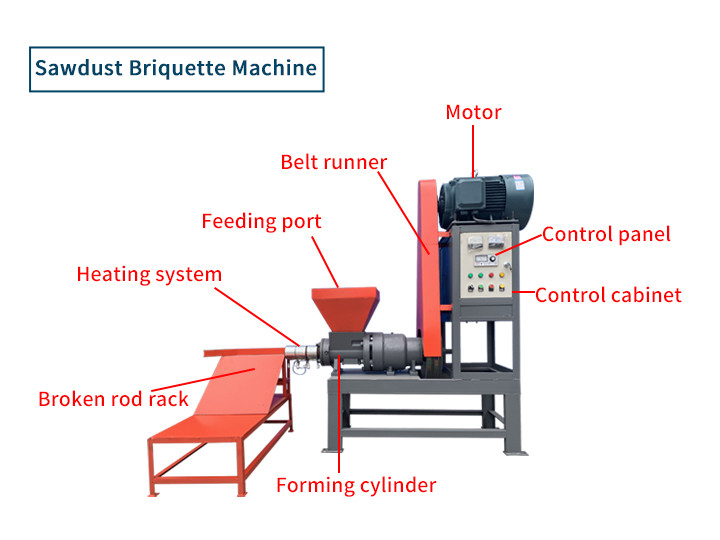

おがくずブリケット製造機の構造

この木くずブリケット機は、主にモーター、制御キャビネット&制御パネル、供給口、成形シリンダー、加熱システムなどで構成されています。

- モーターは高品質のフル銅コアを使用しており、型はクロムマンガン合金で作られており、高温および酸化抵抗に優れています。

- ホッパーは大きな開口部のデザインを採用しており、供給が便利で供給がより均一になります。

- 排出ポートにはさまざまなモデルの型があり、顧客のニーズに応じてカスタマイズすることもできます。

- 排出ポートには破砕棒ラックが装備されており、形成されたバイオマス炭の長さを10〜15cmの間で制御できます。

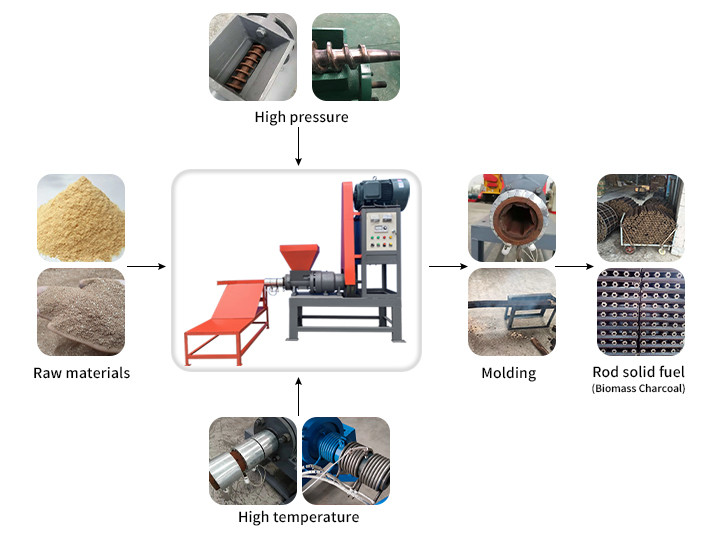

木材おがくずブリケット機の動作原理

- 成形シリンダーの予熱:加熱リングをオンにして、成形シリンダー内の温度を280〜300°Cに加熱します。

- モーターを起動:機器のモーターを起動し、材料を供給する準備をします。

- 供給と押出成形:処理された原材料を供給ポートに入れ、スクリュープロペラが材料を前方に押し出します。

- 高温・高圧成形:高温とスクリュー押出圧力の作用下で、材料中のリグニンが軟化しゼラチン化し、その後型を通して押し出されて中空の棒状燃料が作られます。

おがくずブリケット機の使用に関するヒント

使用准备

- 始動前に機械のオイルレベルを確認してください。約750mlの潤滑剤を充填することをお勧めします。

- 機械を始動する前に、10分間無負荷で運転し、詰まりや clogging がないことを確認してください。異常があれば、直ちに機械を停止し、調査を行ってください。

温度设定

- 原材料に応じて予め設定された温度を調整してください:混合木の木くずは約320°C、米殻は約260°Cです。

- 他の材料は硬度に応じて適切に増減させてください。硬度が約10℃上がるごとに調整します。

使用过程调整

- 温度が高すぎる場合のパフォーマンス(急速に突き出し、黒色になる):スティック本体が茶色になるまで、毎回3°Cずつ温度を徐々に下げて調整します。

- 温度が低すぎるパフォーマンス:(バーの速度が遅く、色が薄い):徐々に温度を上げていき、毎回5℃ずつ増加させ、バーが正常になるまで続けてください。

停机操作

- 機械を停止する前に、ホッパー内の残留物を空にし、逆転ボタンを押してプロペラシャフトから残留物を引き抜いてください。

- 機器をシャットダウンした後、加熱リングは10分間作動し続け、成形シリンダー内の残留物を炭化させます。これは次回の起動を便利にします。

バイオマスブリケット製造機の展示

成形シリンダーの機械マッチング展示

ピニケイブリケット機の重要な作業部品は、スクリュープロペラ、加熱リング、成形シリンダーです。作業の強度が高いため、これらの部品はすぐに摩耗します。

シュリィによって製造されたこれらの部品は品質が良く、非常に耐久性があり、長いサービスライフを持っています。顧客がこれらのアクセサリーを再購入する場合、割引価格で販売することができ、購入数量が多い場合は無料で提供することもできます。

バイオマス木くずブリケット機のパラメータ

| モデル | SL-15 | SL-18 | SL-22 |

| 容量 (kg/h) | 160-200 | 220-260 | 250-300 |

| モーター(kw) | 15 | 18 | 22 |

| 加熱温度(℃) | 260-380 | 260-380 | 260-380 |

| 寸法(mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

おがくずブリケット機に関する関連動画

如果您对木屑制棒机的性能和优点产生了浓厚的兴趣,我们鼓励您立即联系我们的专业团队。我们随时准备为您提供详细信息,回答您的问题,并安排您参观我们的工厂,亲身体验我们木屑制棒机的高效生产和卓越品质。