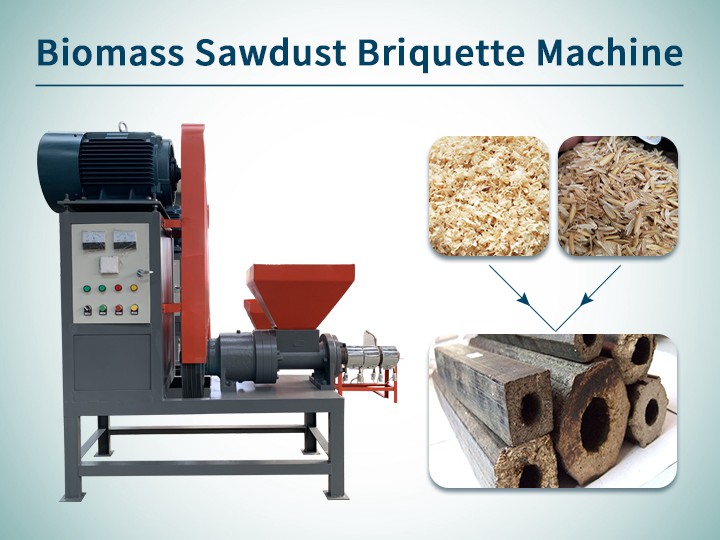

Mesin briket serbuk biomassa menggunakan teknologi pembentukan tanpa pengikat dengan suhu dan tekanan tinggi. Mesin ini dapat memadatkan limbah pertanian dan kehutanan seperti serbuk kayu, serpihan, sekam padi, cangkang kacang tanah, bagasse, dll., menjadi bahan bakar biomassa batang berongga dengan densitas 1,0-1,4g/cm³.

Dibandingkan dengan kayu biasa, briket serbuk gergaji lebih mudah untuk dinyalakan, nilai kalori meningkat lebih dari 20%, polusi lebih rendah, dan densitas lebih tinggi. Ini mudah disimpan, diangkut, dan dibakar dalam waktu lama, memberikan solusi energi bersih yang ekonomis dan praktis untuk limbah pertanian dan kehutanan.

Bahan baku dan aplikasi briket biomassa

Mesin briket serbuk gergaji bahan bakar biomassa cocok untuk berbagai jenis limbah pertanian dan kehutanan yang mengandung lignin, terutama termasuk:

- Serbuk kayu, serbuk bambu, serutan

- Sekam padi, cangkang kacang tanah, tongkol jagung

- Batang kapas, batang tanaman, cabang pemangkasan kebun dan taman

- Bagasse, cangkang kelapa, pabrik furnitur, pabrik produk bambu, limbah tepi pabrik sumpit, dll.

Persyaratan bahan baku: ukuran partikel ≤ 5 mm; kadar air ≤ 12%. (Penghancur chip kayu dan pengering serbuk gergaji putar drum dapat digunakan untuk pra-perlakuan)

Produk jadi ekstruder briket serbuk kayu

Batang bahan bakar biomassa yang dibuat oleh mesin briket serbuk gergaji banyak digunakan di berbagai bidang:

- Bahan bakar pemanas sipil: dapat langsung digunakan sebagai bahan bakar untuk perapian rumah dan kompor pemanas, terutama banyak digunakan di Eropa dan Amerika Serikat.

- Bahan baku untuk produksi industri: cocok untuk pengolahan industri seperti pembuatan furnitur dan produk kayu.

- Kreatif dan kerajinan tangan: sebagian batang kayu dapat digunakan dalam kerajinan tangan, produksi kreatif dan bidang khusus lainnya.

- Penggunaan pertanian: abu setelah pembakaran dapat digunakan sebagai pupuk fosfor, mendorong penggunaan kembali sumber daya.

- Penyimpanan dan transportasi yang nyaman: produk jadi memiliki kepadatan tinggi, volume kecil, dan kemasan yang mudah (kemasan shrink-wrap), yang memudahkan penyimpanan dan transportasi, serta mengurangi biaya.

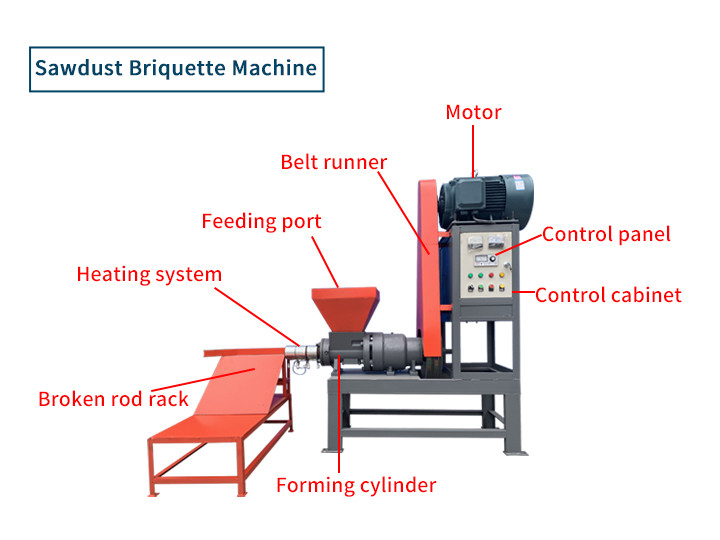

Struktur Mesin Pembuat Briket Serbuk Kayu

Mesin briket serbuk gergaji ini terutama terdiri dari motor, kabinet kontrol & panel kontrol, port pengumpanan, silinder pembentuk, sistem pemanas, dll.

- Motor menggunakan motor berkualitas tinggi dengan inti tembaga penuh, dan cetakan terbuat dari paduan krom-mangan, yang memiliki ketahanan yang baik terhadap suhu tinggi dan oksidasi.

- Hopper mengadopsi desain bukaan besar, yang memudahkan pengumpanan dan membuat pengumpanan lebih merata.

- Ada berbagai model cetakan dari port pembuangan, dan juga dapat disesuaikan sesuai dengan kebutuhan pelanggan.

- Port pembuangan dilengkapi dengan rak batang patah, yang dapat mengontrol panjang arang biomassa yang terbentuk antara 10-15cm.

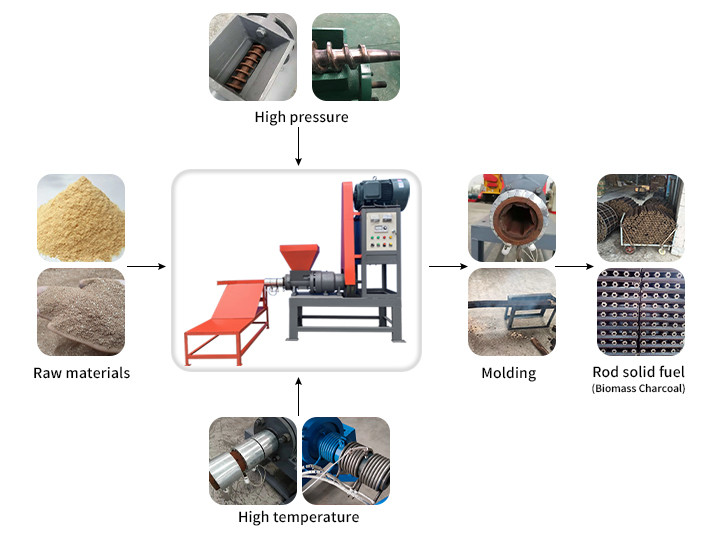

Prinsip Kerja Mesin Briket Serbuk Kayu

- Pemanasan awal silinder pembentuk: nyalakan cincin pemanas untuk memanaskan suhu di dalam silinder pembentuk hingga 280-300°C.

- Nyalakan motor: nyalakan motor peralatan, siap untuk memberi bahan.

- Pengumpanan dan pembentukan ekstrusi: masukkan bahan mentah yang telah diproses ke dalam port pengumpanan, dan propeller sekrup akan mengekstrusi bahan ke depan.

- Pencetakan suhu tinggi dan tekanan tinggi: di bawah pengaruh suhu tinggi dan tekanan ekstrusi sekrup, lignin dalam bahan akan melunak dan mengental, dan kemudian diekstrusi melalui cetakan untuk membuat bahan bakar berbentuk batang berongga.

Tips untuk penggunaan mesin briket serbuk kayu

Persiapan penggunaan

- Periksa level oli mesin sebelum dinyalakan, disarankan untuk mengisi sekitar 750ml pelumas.

- Sebelum memulai mesin, jalankan tanpa beban selama 10 menit untuk memastikan tidak ada penyumbatan atau kemacetan. Jika ada ketidaknormalan, hentikan mesin segera untuk penyelidikan.

Pengaturan suhu

- Sesuaikan suhu yang telah ditentukan sesuai dengan bahan mentah: serbuk gergaji dari campuran kayu sekitar 320°C, sekam padi sekitar 260°C.

- Bahan lain sesuai dengan kekerasan yang sesuai meningkat atau menurun, setiap peningkatan kekerasan sekitar 10 ℃.

Penyesuaian proses penggunaan

- Kinerja suhu terlalu tinggi (terlalu cepat menempel, warna hitam): sesuaikan suhu ke bawah secara bertahap sebesar 3°C setiap kali, sampai badan stik berwarna coklat.

- Suhu terlalu rendah kinerja: (kecepatan batang lambat, warnanya terang): secara bertahap sesuaikan suhu ke atas, setiap kali meningkat 5 ℃, sampai batang normal.

Operasi penonaktifan

- Sebelum menghentikan mesin, kosongkan material sisa di corong dan tekan tombol mundur untuk menarik material sisa dari poros propeller.

- Setelah mematikan peralatan, cincin pemanas akan terus bekerja selama 10 menit untuk mengkarbonisasi sisa-sisa di silinder pencetakan, yang memudahkan untuk startup berikutnya.

Tampilan mesin pembuat briket biomassa

Tampilan silinder pencetakan yang cocok dengan mesin

Bagian penting dari mesin briket pini kay adalah sekrup propeller, cincin pemanas, dan silinder pencetak. Karena intensitas kerja yang tinggi, bagian-bagian ini cepat aus.

Bagian-bagian ini yang diproduksi oleh Shuliy memiliki kualitas yang baik, sangat tahan lama, dan memiliki masa pakai yang panjang. Jika pelanggan membeli kembali aksesori ini, mereka dapat dijual dengan diskon, dan dapat diberikan secara gratis jika jumlah pembeliannya besar.

Parameter mesin briket serbuk biomassa

| Model | SL-15 | SL-18 | SL-22 |

| Kapasitas (kg/j) | 160-200 | 220-260 | 250-300 |

| Motor (kw) | 15 | 18 | 22 |

| Suhu pemanasan (℃) | 260-380 | 260-380 | 260-380 |

| Dimensi (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

Video terkait tentang mesin briket serbuk kayu

Jika Anda memiliki minat yang kuat terhadap kinerja dan manfaat mesin briket serbuk gergaji kayu, kami mendorong Anda untuk segera menghubungi tim profesional kami. Kami siap memberikan informasi terperinci, menjawab pertanyaan Anda, dan mengatur kunjungan Anda ke pabrik kami untuk merasakan produksi yang efisien dan kualitas unggul dari mesin briket kayu kami.