Mesin pencacah kayu drum dapat memotong batang, cabang, papan, bambu, batang kapas, dan bahan baku serat kayu atau non-kayu lainnya menjadi irisan dengan spesifikasi seragam (20-40mm panjang, 3-5mm ketebalan), dengan tingkat kelayakan lebih dari 97%. Ini banyak digunakan di pabrik kertas, pabrik papan partikel, pabrik papan serat medium dan tinggi, pembangkit listrik biomassa, basis ekspor chip kayu, dan sebagainya.

Keuntungan dari mesin pembuat serpihan kayu

- Adaptabilitas yang kuat: dapat dipasang dan digunakan di berbagai lingkungan geografis dan kondisi iklim tanpa terpengaruh oleh musim.

- Tanpa pemasangan fondasi: peralatan dapat digunakan dalam waktu 1-2 hari setelah tiba, menghemat 10-15 hari.

- Penghematan biaya: tanpa konstruksi fondasi dapat menghemat pengguna sekitar $500-2000 dalam biaya tenaga kerja dan material (tergantung pada model).

- Pemasangan yang fleksibel dan nyaman: tidak perlu memperbaiki lokasi pemasangan, penyetelan yang sederhana, meningkatkan fleksibilitas dan mobilitas peralatan.

- Arah pembuangan yang dapat disesuaikan: dilengkapi dengan perangkat pembuangan kedua, arah pembuangan dapat disesuaikan secara fleksibel sesuai kebutuhan.

- Output besar: kapasitas pemrosesan harian 30-300 ton, untuk menyesuaikan dengan kebutuhan produksi pengguna yang berbeda.

- Operasi yang mudah: desain struktur yang wajar, operasi dan pemeliharaan yang mudah, cocok untuk semua jenis pengguna.

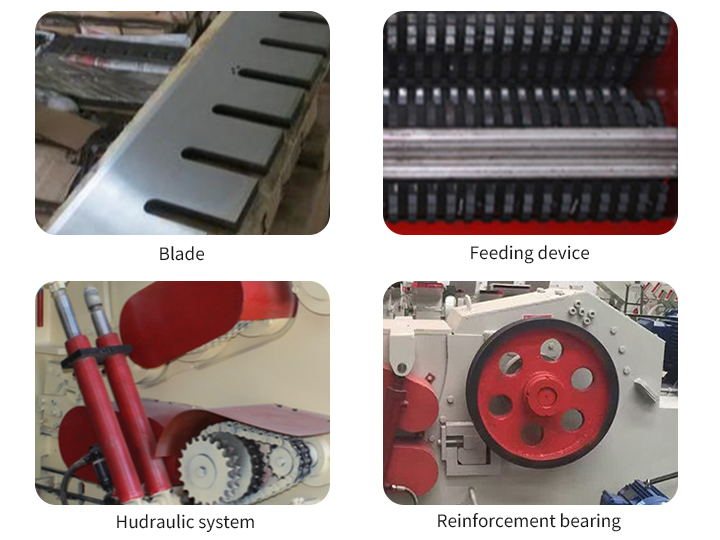

struktur utama mesin pemotong kayu

Mesin pencacah kayu drum terdiri dari mesin utama yang dilas dari pelat baja berkekuatan tinggi, sistem alat pemotong, rol pengumpan atas dan bawah, sabuk konveyor, inlet dan outlet, motor, dan sistem hidrolik.

Dengan struktur yang kokoh, operasi yang lancar, dan kerja sama sinergis dari semua bagian, alat ini dapat menyelesaikan operasi pemotongan kayu dengan efisien dan cocok untuk berbagai kondisi kerja.

Prinsip kerja mesin penggiling kayu drum

Mesin pencacah kayu drum mewujudkan transformasi dari bahan mentah menjadi serpihan kayu halus dalam tiga tahap, dengan efisiensi tinggi dan konsumsi energi yang terkontrol:

Penekanan umpan hidrolik

- Bahan baku dimasukkan melalui sabuk konveyor yang lebar, dan sistem hidrolik rol ganda secara otomatis memadatkan dan memajukan bahan dengan kecepatan yang seragam.

- Mengatasi resistensi terhadap deformasi cabang memastikan stabilitas pemberian bahan yang terus menerus.

- Celah tekanan roller yang dapat disesuaikan secara cerdas, cocok untuk semua jenis bahan baku dengan diameter ≤ 350mm.

Pemotongan dinamis multi-bilah

- Drum pisau inti mengintegrasikan set pisau terbang paduan kekuatan tinggi, berputar pada kecepatan tinggi 960 rpm.

- Pisau mengadopsi tata letak spiral radial, yang menempel pada permukaan bahan baku selama seluruh proses pemotongan.

- Penyiraman berlapis dengan resistensi rendah dicapai, secara signifikan mengurangi tingkat serpihan dan memperpanjang umur alat.

Output penyortiran siklon

- Serutan kayu yang dipotong menembus lubang-lubang pada layar drum pisau dan diangkut secara terarah oleh aliran udara negatif berkecepatan tinggi yang dihasilkan oleh impeller pisau.

- Layar grading bawaan secara otomatis memisahkan serpihan yang terlalu besar, dan serpihan yang memenuhi syarat dikeluarkan dengan bersih melalui saluran udara tertutup.

- Kotoran dikembalikan ke area penghancuran untuk pemrosesan sekunder untuk memastikan bahwa diameter bagian jadi akurat dan sesuai standar (±1mm kesalahan).

Mesin pencacah kayu dapat dihancurkan lebih lanjut menjadi serpihan kayu dengan menambahkan penghancur palu kayu di bagian belakang mesin, dan kemudian digunakan untuk pembuatan arang dan operasi lainnya.

Produk jadi yang dapat Anda dapatkan

Produk jadi yang dihasilkan oleh mesin pencacah kayu drum ini memiliki ukuran partikel yang seragam, tekstur halus, dan permukaan yang halus, yang dapat digunakan secara luas dalam pengerjaan kayu, pembuatan kertas, dan bidang lainnya.

Parameter mesin serut kayu drum

| Model | SL215 | SL216 | SL218 | SL2113 |

| Ukuran bahan baku (mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Jumlah pisau (buah) | 2 | 2 | 2 | 2 |

| Kecepatan putar pisau (rpm) | 592 | 590 | 650 | 500 |

| Diameter bahan baku (mm) | 160 | 230 | 300 | 450 |

| Ukuran serutan kayu (mm) | 30 | 30 | 30 | 38 |

| Kapasitas (t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Daya motor utama (kw) | 45 | 55 | 110 | 200-250 |

| Daya motor roller pakan (kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Daya motor pompa minyak (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Berat mesin (kg) | 3590 | 5030 | 7000 | 11840 |

| Ukuran mesin (mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Daya motor konveyor (kw) | 3 | 3 | 3 | 3 |

Terima kasih telah membaca tentang mesin pencacah kayu. Jika Anda tertarik dengan mesin kami atau memiliki pertanyaan, jangan ragu untuk menghubungi kami. Anda dapat memberi tahu kami persyaratan spesifik sebelum memesan mesin pencacah kayu. Untuk melindungi kepentingan pelanggan kami, kami akan memilih mesin yang paling sesuai untuk Anda. Semua pelanggan yang tertarik dengan mesin kami juga dipersilakan untuk mengunjungi pabrik kami. Kami berharap dapat menjalin hubungan kerjasama dengan Anda.