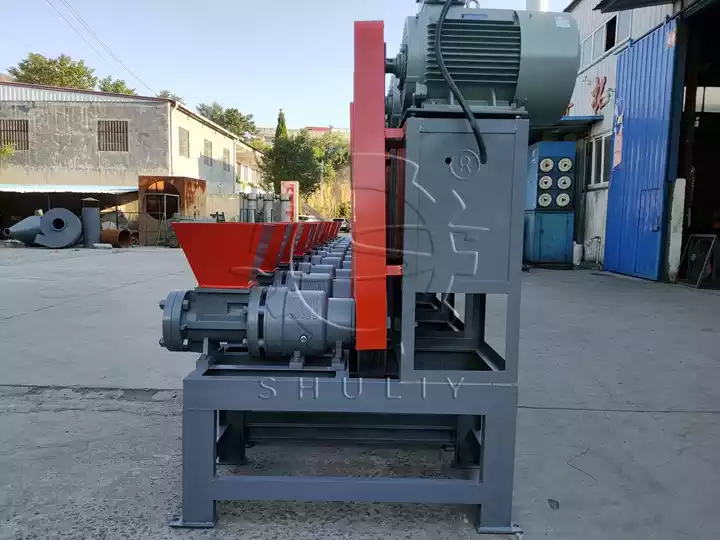

آلات ضغط نشارة الخشب هي خيار استثماري شائع لمصانع معالجة الخشب ومؤسسات الطاقة الحيوية. من خلال ضغط المواد النفايات مثل النشارة، رقائق الخشب، والقش إلى حبيبات وقود، فهي لا تحافظ على الموارد فحسب، بل تولد أيضًا فوائد اقتصادية كبيرة. فماذا عن تكلفة الاستثمار في آلة ضغط نشارة الخشب عالية الكفاءة؟ تقدم هذه المقالة تفصيلًا دقيقًا.

الوظائف الرئيسية والمواد الخام المناسبة

يمكن لآلات الضغط ضغط مواد الكتلة الحيوية المختلفة إلى كريات وقود موحدة، مما يسهل النقل والتخزين. تشمل المواد الخام المناسبة:

- نفايات الخشب: نشارة الخشب، رقائق الخشب، الشرائح، إلخ.

- قمح المحاصيل: سيقان الذرة، قش القمح، قش الأرز، إلخ.

- مواد الكتلة الحيوية الأخرى: قشور جوز الهند، قشور النخيل، قشور الفول السوداني، إلخ.

من خلال التشكيل بالضغط بدرجة حرارة عالية وضغط عالي، تتميز الكريات النهائية بشكل موحد، وكثافة عالية، وكفاءة احتراق ممتازة. وتستخدم على نطاق واسع للتدفئة المنزلية، ووقود الغلايات، والاحتراق الصناعي.

العوامل الرئيسية التي تؤثر على سعر آلة ضغط نشارة الخشب

تتأثر أسعار آلة ضغط نشارة الخشب بحوالي عوامل متعددة، مع تباينات سعرية كبيرة عبر النماذج والتكوينات المختلفة. العوامل الأساسية تشمل:

- سعة الإنتاج: آلات الكريات ذات الإنتاجية الأعلى يمكنها ضغط المزيد من حبيبات الوقود في الساعة، مما يفرض أسعارًا أعلى نسبيًا.

- مستوى الأتمتة: هناك فروق سعر كبيرة بين النماذج اليدوية، شبه الأوتوماتيكية، والأوتوماتيكية بالكامل. الوحدات الأوتوماتيكية بالكامل تدمج وظائف التغذية، والضغط، والتفريغ، وتوفر عائد استثمار أسرع.

- جودة المادة والمتانة: آلات الكرّ ذات الهيكل المصنوع من فولاذ عالي القوة وتصاميم مقاومة للتآكل تتميز بعمر خدمة ممتد وتكاليف صيانة أقل، وتفرض أسعارًا أعلى قليلاً.

- ميزات إضافية: خيارات مثل أنظمة التبريد التلقائية، قوالب التشكيل المتنوعة، وأنظمة التعبئة التلقائية تؤثر أيضًا على التسعير.

مرجع تكلفة استثمار الآلة

استنادًا إلى ظروف السوق ونماذج المعدات، يتراوح السعر التقريبي لآلات الضغط على النحو التالي:

- آلة ضغط الكريات الصغيرة: حوالي 5000-15000 دولار أمريكي، مناسبة للورش الصغيرة والمصانع المنزلية.

- آلة ضغط الكريات متوسطة الحجم: حوالي 15000-35000 دولار أمريكي، مناسبة للمؤسسات الصغيرة والمتوسطة لتحقيق إنتاج ثابت.

- آلات أوتوماتيكية بالكامل كبيرة: حوالي 35000-80000 دولار، مناسبة للإنتاج على نطاق صناعي ومحطات وقود الكتلة الحيوية الكبيرة.

الاستثمار في آلة صنع الكريات من نشارة الخشب عالية الكفاءة لا يعظم فقط من استغلال موارد الخشب والنفايات القش، بل يحقق أيضًا إيرادات مستدامة من خلال مبيعات حبيبات الوقود، محققًا فوائد بيئية واقتصادية على حد سواء.

فهم وظيفة المعدات، سعة الإنتاج، ومستويات الأتمتة يساعد الشركات على اختيار النموذج الأنسب لاحتياجاتها، مما يتيح استغلال الموارد بشكل أمثل ونمو الأرباح على المدى الطويل. للاستفسارات، يرجى الاتصال بنا!