随着印度经济的发展,当地环境污染问题日益严重。特别是生产中生物质废料和碎屑的回收利用严重不足,造成了巨大的资源浪费和环境污染。如何在碳化过程中实现连续碳化炉的自动无烟碳化?

连续碳化炉是如何工作的?

连续碳化炉是一种新型的炭粉碳化机,在生产成品炭的同时进料,属于外加热式烘干碳化机。整个生产过程不产生有害气体,没有大量烟气排放。产生的烟气可以回收利用,不会污染环境。这种环保的碳化机用途广泛,可以将一些生物质废料转化为优质资源,是缓解资源短缺的最佳选择。

连续碳化炉的特点是什么?

连续碳化炉利用干馏碳化的原理,在缺氧条件下对炉内的生物质原料进行热解,形成可燃气体、焦油和炭。它具有结构独特、有效容积大、碳化工艺先进、周期短、产量高、环保性能好和使用寿命长等优点。

Shuliy Machinery 可以为客户生产用于碳化各种高、中、低温木炭的炭化炉。连续炭化炉采用高科技净化技术和特殊的耐高温不锈钢。它具有坚固耐用、不变形、不氧化、良好的保温性能、操作简单、安全可靠等优点。

环保型碳化炉主要包括两系列五种自燃和气化。连续碳化炉在原有碳化机的基础上增加了烟气回收装置。经过回收的烟气可以做到无尘无烟。回收的烟气可以像液化气一样点燃,剩余的气体可以被干燥机使用。

连续碳化炉可以利用在生物质原料碳化过程中产生的可燃气体,如一氧化碳、甲烷或氢气。同时,它还通过烟气分离装置分离木焦油、木醋酸和其他杂质,以获得纯净的可燃气体。这些可燃气体通过引风机充分燃烧,进入自给自足的燃烧器,用于加热主气缸。在加热到一定温度后,可以进行碳化,然后逐渐关闭气化器,打开碳化主机烟气阀。最后,达到碳化过程的可燃气体可以自给自足。

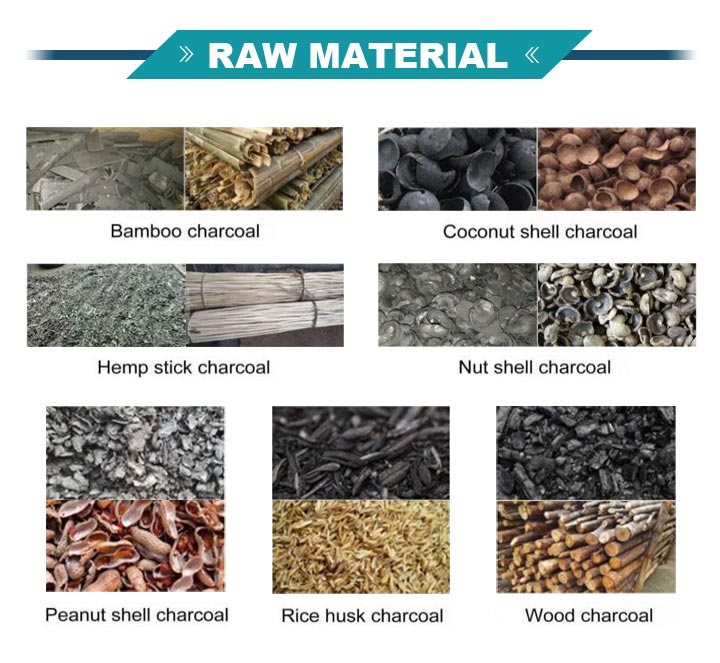

哪些材料可以 被 连续碳化炉工艺?

连续碳化炉使用废弃物作为原材料,如花生壳、木屑、玉米秸秆、甘蔗渣、树枝、稻壳、竹屑、高粱杆、向日葵壳、酒糟、玉米秸秆、高粱杆、椰子壳、咖啡渣、棉秆、豆杆、枯叶等。这些材料经过高温处理后,制成高质量、环保的木炭或木炭粉。环保碳化炉生产的碳材料干净无毒,热能高,市场销售良好,前景光明。

节能和环保是印度社会每个人都非常重视的问题。燃烧煤炭产生的热量已经不再符合印度的环保要求。连续碳化炉的特性经过反复测试,难以获得。生物质燃料在连续碳化炉中碳化,不仅无烟且环保,而且碳化效率非常高。