Enviamos com sucesso uma máquina de briquetes SL-160 para o Vietnã. O cliente opera uma fazenda de grande escala onde as demandas de aquecimento no inverno são particularmente significativas. Métodos de aquecimento tradicionais não só apresentam baixa eficiência, como também acarretam problemas como combustão incompleta e altos custos.

Após avaliar múltiplas soluções de processamento de combustível, o cliente optou por adquirir a máquina de briquetes de carvão. Este equipamento irá processar matérias-primas em briquetes de carvão de alta densidade, proporcionando à fazenda uma fonte de calor econômica, limpa e estável.

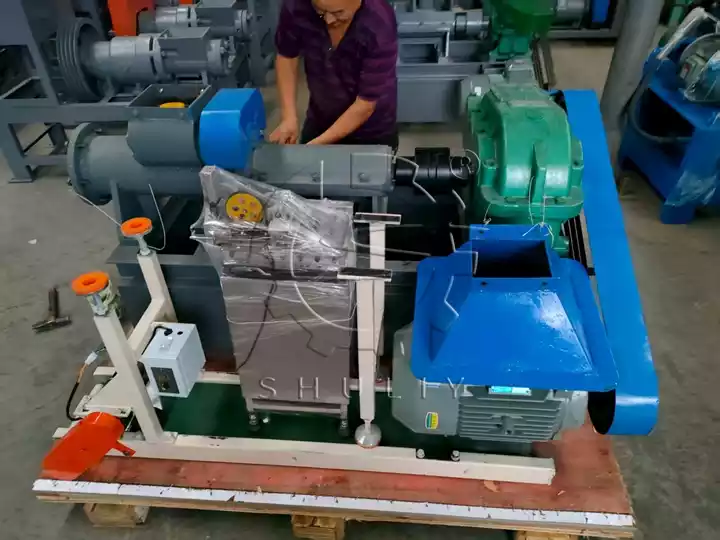

Parâmetros e configuração da máquina de briquetes de carvão

As principais especificações da máquina de briquetes enviada desta vez são as seguintes:

- Modelo: SL-160

- Tensão: 380V, 50Hz, alimentação trifásica

- Potência: 11Kw

- Produção: 500kg/h

- Dimensões: 1950×1260×1080mm

- Peso: 160kg

- Moldes: molde hexagonal padrão (40mm lados opostos) incluído, além de um conjunto adicional de moldes circulares (15mm de diâmetro) para atender a diversos requisitos de briquetes de carvão.

- Além disso, este equipamento inclui um sistema de corte + transportador (comprimento de 1,5m, alimentação trifásica 380V) para corte e transporte automáticos dos briquetes de carvão, aumentando significativamente a eficiência da produção.

Vantagens e valor de aplicação da extrusora de briquetes de carvão

- Produção de alta eficiência: produz aproximadamente 500kg de briquetes de carvão por hora, atendendo plenamente às demandas de aquecimento diárias em fazendas de pecuária.

- Modelagem versátil: trocando moldes, podem ser produzidos briquetes hexagonais ou circulares para se adequarem a diferentes cenários de uso.

- Combustão estável: os briquetes formados apresentam alta densidade, tempo de queima prolongado e valor calorífico consistente, tornando-os particularmente adequados para aquecimento de longo prazo em fazendas de pecuária.

- Econômico e ecológico: utiliza uma ampla gama de matérias-primas, incluindo palha agrícola e pó de carvão, possibilitando a reciclagem de recursos e reduzindo os custos da fazenda.

- Alta automação: equipado com sistema de transportador + corte, minimiza a mão de obra enquanto garante operação simples e segura.

Após concluir a comissionamento do equipamento, nossa equipe técnica realizou rigidas inspeções de qualidade para garantir o funcionamento estável da máquina. Em seguida, os trabalhadores reforçaram a embalagem da máquina de briquetes de carvão e de seus acessórios de transporte/corte para prevenir danos durante o trânsito. No dia do embarque, o equipamento foi carregado com segurança em um caminhão e partiu sem problemas para o Vietnã.