La máquina de briquetas de carbón para barbacoa es un equipo de moldeo que presiona de manera eficiente materias primas como polvo de carbón, polvo de carbón vegetal, polvo mineral, polvo de coque, residuos de biomasa, etc. A través del rodillo de molde reemplazable de 360° (con una precisión de ±0.1mm), las materias primas se pueden prensar en 12 formas de bola personalizadas, como redondas/elípticas/almohada.

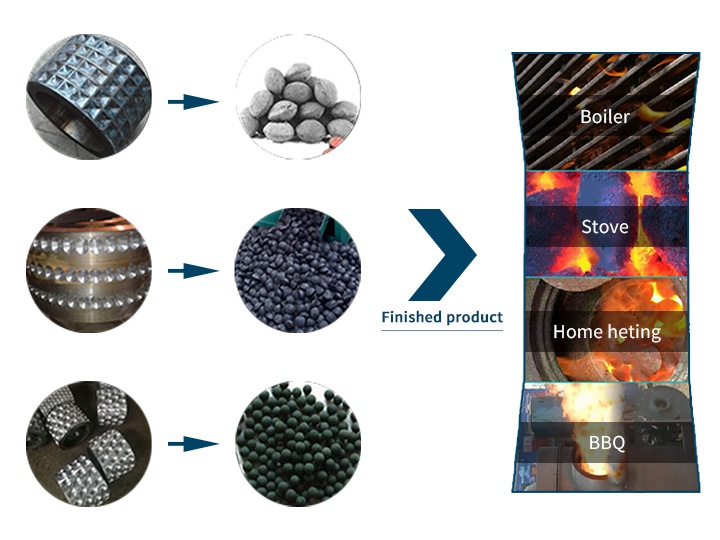

La tasa de formación de bolas de carbón es ≥98%, la dureza supera 90kg/cm² y el valor calorífico de combustión alcanza 7500kcal/kg. Se utiliza ampliamente en metalurgia, industria química, electricidad, energía, procesamiento de combustibles y otras industrias.

En comparación con el carbón vegetal tradicional, el carbón para barbacoa formado tiene las ventajas de ser inodoro, no tóxico, sin humo, de alto poder calorífico, fácil de encender, fácil de transportar y almacenar, etc. Es una opción de combustible ideal para el ahorro de energía y la protección del medio ambiente.

Ya sea que lo estés utilizando para la producción de carbón vegetal para barbacoas en casa o para el procesamiento por lotes de combustibles industriales. Ofrecemos una variedad de modelos y formas de moldes para satisfacer las necesidades de diferentes producciones y personalización de formas, ayudándote a llevar a cabo de manera eficiente el negocio de producción de bolas de carbón.

Estructura principal de la máquina de briquetas de bolas de carbón

- Parte de alimentación: consiste en un embudo y un dispositivo de alimentación por tornillo, que se encarga de alimentar los materiales de manera uniforme y cuantitativa entre los rodillos de presión. El alimentador de tornillo es impulsado por un motor de regulación de velocidad electromagnético, lo que garantiza un suministro estable de material y asegura la calidad de la formación de bolas.

- Parte de transmisión: incluye motor, correa en triángulo, reductor, engranaje abierto, etc. La potencia se transmite al eje principal a través del acoplamiento, y luego se impulsa el eje esclavo para sincronizar la operación y realizar la acción de prensado de bolas.

- Parte de moldeo: consiste en un par de rodillos de presión de igual tamaño con agujeros de molde hemisféricos dispuestos regularmente en la superficie. Equipado con un dispositivo de protección hidráulica, cuando se encuentra con objetos duros o sobrecarga, puede descargar automáticamente la presión para proteger el rodillo de presión de daños.

Este diseño estructural garantiza la alta eficiencia, estabilidad y seguridad de la máquina de briquetas de carbón en forma de bola, que es la garantía principal para lograr un moldeo de carbón para barbacoa de alta calidad.

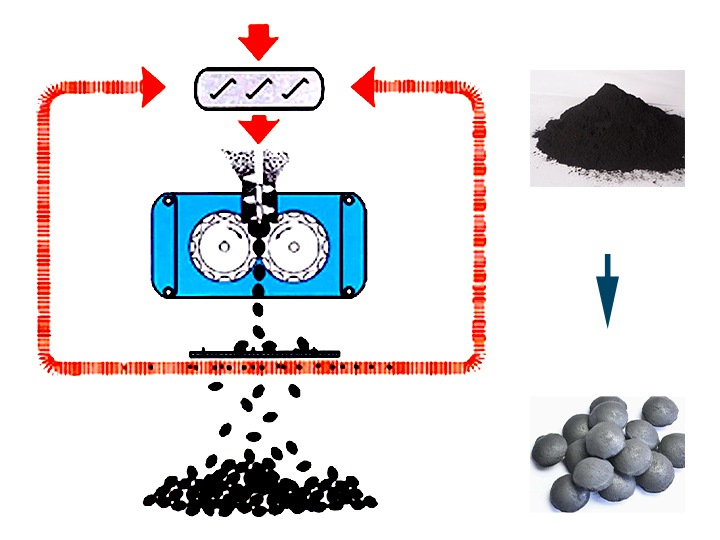

Principio de funcionamiento de la máquina de prensado de carbón

La parte principal de la máquina de briquetas de carbón es un par de ejes rotativos del mismo tamaño, con muchos sockets hemisféricos del mismo tamaño y dispuestos de manera regular en la superficie.

- El material procesado entrará a través del puerto de alimentación y será comprimido en los orificios hemisféricos a ambos lados bajo la acción de su gravedad y la presión de los rodillos a ambos lados.

- Los casquillos hemisféricos a ambos lados se fusionan en una esfera completa, y las materias primas en su interior se comprimirán gradualmente, y finalmente formarán el briquete de bola de carbón.

- Con el movimiento adicional del eje, la bola de carbón formada cae por el puerto de descarga.

Ventajas de la máquina para hacer briquetas de carbón

- Quema más tiempo y ahorra más carbón: después de presionar el polvo de carbón en bolas, quema más tiempo y de manera más eficiente que el carbón ordinario.

- Protección del medio ambiente y ahorro de energía: los briquetas prensadas no humean, no tienen olor y generan un alto calor, adecuadas para barbacoa y calefacción, limpias y ahorradoras de energía.

- Equipo de protección automático: hay un dispositivo de protección hidráulico; si la máquina entra en contacto con objetos duros, puede descargarse automáticamente, sin dañar el rodillo de presión.

- Alimentación más suave: el sistema de alimentación especialmente diseñado puede presionar incluso polvo ligero (como el polvo de carbón) en bolas, no es fácil que se bloquee el material.

- El sistema de transmisión es más duradero: el dispositivo de transmisión está cerrado, no es fácil que entre ceniza, menos ruido, menos desgaste, mayor tiempo de uso.

- El estilo de prensado se puede personalizar: se puede hacer en forma de bola redonda, forma de almohada, forma de huevo y otras formas, y también se puede personalizar en tamaño y estilo según los requisitos de los clientes.

Requisitos de materias primas y aplicación de briquetas de carbón

La máquina de briquetas de carbón en forma de bola se puede utilizar para prensar polvo de carbón, polvo de hierro, carbón coquizable, polvo de aluminio, virutas de hierro, escamas de óxido de hierro, polvo de carbono, polvo de carbono, escoria, yeso, relaves, lodo, caolín, carbón activado y polvo de coque, etc.

La finura del material debe ser inferior a 3 mm, y el contenido de humedad debe estar entre el 8 y el 12%. El aglutinante u otros aditivos (por ejemplo, desulfurados) deben ser preparados por los usuarios según el tipo de carbón y el entorno operativo. Los productos finales se utilizan ampliamente en industrias como la refractaria, plantas de energía, metalurgia, química, energía, transporte, calefacción y otras.

Diferentes moldes de la máquina de moldeo de bolas de carbón

Dependiendo de la forma y el tamaño de las bolas de carbón para BBQ que cada persona necesite, preparamos diferentes moldes para elegir, también puedes decirnos el producto terminado que deseas, y podemos personalizarlo.

Exhibición de la máquina de briquetas de carbón para barbacoa

Parámetros técnicos de la máquina extrusora de bolas de carbón

La máquina de briquetas de carbón para barbacoa demuestra tecnología avanzada y un rendimiento excelente, y su información de parámetros satisface las necesidades de los usuarios en todos los aspectos. La alta capacidad de producción y el tamaño de bola ajustable le proporcionan una excelente flexibilidad y eficiencia de producción en el proceso de producción de carbón para barbacoa.

| Modelo | Capacidad | Potencia | Ancho de rollo | Diámetro de rollo |

| SLYQJ-360 | 2t/h | 7.5kw | 250mm | 360mm |

| SLYQJ-400 | 4t/h | 11-15kw | 280mm | 400mm |

| SLYQJ-500 | 6t/h | 18.5-22kw | 300mm | 500mm |

| SLYQJ-650 | 10t/h | 20-30kw | 336mm | 650mm |

| SLYQJ-750 | 15t/h | 45kw | 400mm | 750mm |

| SLYQJ-850 | 25t/h | 75kw | 500mm | 850mm |

| SLYQJ-1250 | 35t/h | 130kw | 650mm | 1250mm |

Video relacionado de la máquina de briquetas de bolas de carbón

Además, tenemos otras máquinas de carbón para elegir. Si está interesado, puede hacer clic en: Máquina hidráulica y mecánica para briquetas de carbón de cachimba y Máquina de carbón de panal | Máquina para fabricar briquetas de carbón.

Para obtener más información sobre el excelente rendimiento y las ventajas técnicas de la máquina de briquetas de carbón en bola para BBQ, le animamos a que se ponga en contacto con nosotros de manera activa. Nuestro equipo profesional estará encantado de proporcionarle información detallada sobre el producto, sugerencias personalizadas y soluciones. Además, le invitamos cordialmente a visitar nuestra fábrica para experimentar la operación eficiente y la tecnología avanzada de la máquina de bolas de carbón para BBQ.