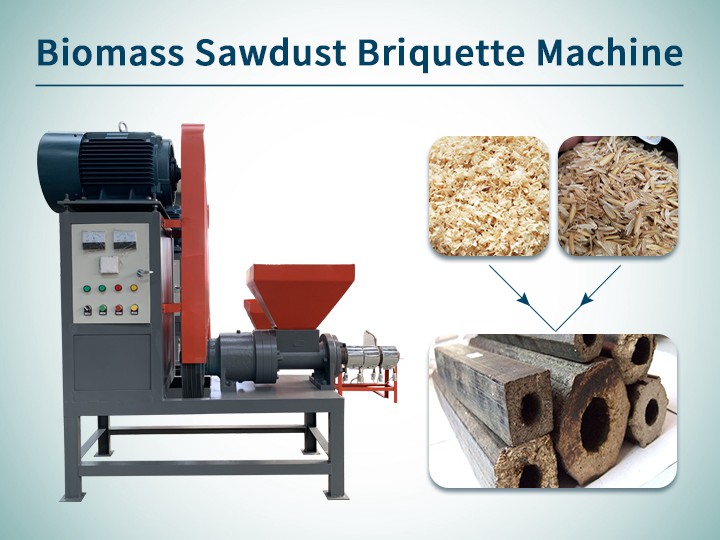

Die Biomasse-Sägemehlbrikettmaschine verwendet eine bindemittelfreie Formgebungstechnologie bei hohen Temperaturen und hohem Druck. Sie kann landwirtschaftliche und forstwirtschaftliche Abfälle wie Sägemehl, Späne, Reishülsen, Erdnussschalen, Bagasse usw. zu hohlen Stäben aus Biomassebrennstoff mit einer Dichte von 1,0-1,4 g/cm³ pressen.

Im Vergleich zu gewöhnlichem Holz ist der Sägemehlbriketts leichter zu entzünden, der Heizwert ist um mehr als 20 % erhöht, die Verschmutzung ist geringer und die Dichte ist höher. Er ist einfach zu lagern, zu transportieren und lange Zeit zu verbrennen und bietet eine wirtschaftliche und praktische Lösung für saubere Energie aus land- und forstwirtschaftlichen Abfällen.

Rohstoffe und Anwendungen von Biomassebriketts

Die Biomassebrennstoff-Sägemehl-Brikettmaschine ist für viele Arten von landwirtschaftlichen und forstwirtschaftlichen Abfällen geeignet, die Lignin enthalten, hauptsächlich einschließlich:

- Holzspäne, Bambusspäne, Späne

- Reis-Hülsen, Erdnussschalen, Maiskolben

- Baumwollstängel, Ernteabfälle, Obst- und Gartenbaumschnittäste

- Bagasse, Kokosnussschalen, Möbelwerkstätten, Bambusprodukte, Abfälle von Essstäbchenfabriken usw.

Rohmaterialanforderungen: Partikelgröße ≤ 5 mm; Feuchtigkeitsgehalt ≤ 12%. (Holzhackmaschine und Trommeltrockner können für die Vorbehandlung verwendet werden)

Fertigerzeugnis von Holzsägemehlbrikett-Extruder

Die von der Sägemehl-Brikettmaschine hergestellten Biomassebrennstoffstäbe werden in vielen Bereichen weit verbreitet:

- Heizöl für Zivilisten: Es kann direkt als Brennstoff für Kamine und Heizöfen zu Hause verwendet werden, insbesondere in Europa und den Vereinigten Staaten weit verbreitet.

- Rohmaterial für die industrielle Produktion: Es eignet sich für die industrielle Verarbeitung wie Möbelherstellung und Holzprodukte.

- Kreatives und Handwerk: Ein Teil der Holzstäbchen kann in Handwerkskunst, kreativer Produktion und anderen speziellen Bereichen verwendet werden.

- Agrarische Nutzung: Die Asche nach dem Verbrennen kann als Phosphordünger verwendet werden, was die Wiederverwendung von Ressourcen fördert.

- Praktische Lagerung und Transport: Das fertige Produkt hat eine hohe Dichte, ein kleines Volumen und eine einfache Verpackung (Schrumpfverpackung), was die Lagerung und den Transport erleichtert und die Kosten senkt.

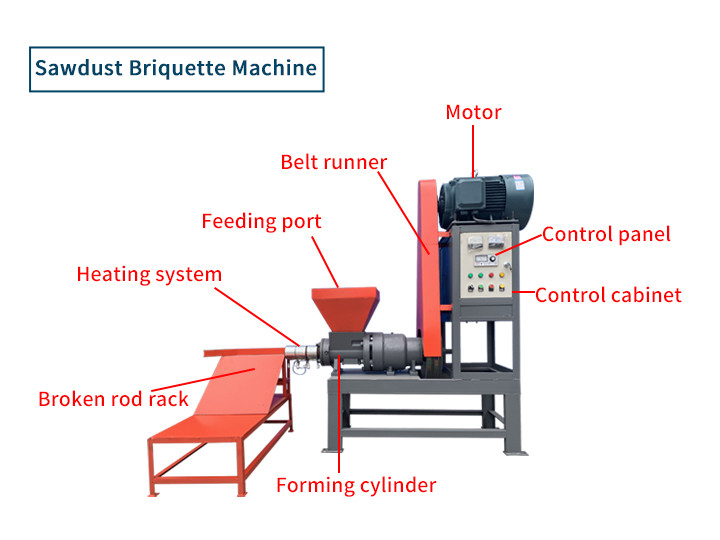

Aufbau der Maschine zur Herstellung von Sägespänebriketts

Diese Sägemehlbrikettmaschine besteht hauptsächlich aus einem Motor, einem Steuerkasten & Bedienfeld, einem Einfülltrichter, einem Formzylinder, einem Heizsystem usw.

- Der Motor verwendet einen hochwertigen Motor mit einem Vollkupferkern, und die Form ist aus einer Chrom-Mangan-Legierung gefertigt, die eine gute Hochtemperatur- und Oxidationsbeständigkeit aufweist.

- Der Trichter hat ein großes Öffnungsdesign, das das Befüllen erleichtert und das Füttern gleichmäßiger macht.

- Es gibt eine Vielzahl von Modellen von Formen am Auslass, die auch nach Kundenwunsch angepasst werden können.

- Der Auslass ist mit einem gebrochenen Stangenregal ausgestattet, das die Länge des geformten Biomassekohle zwischen 10-15 cm steuern kann.

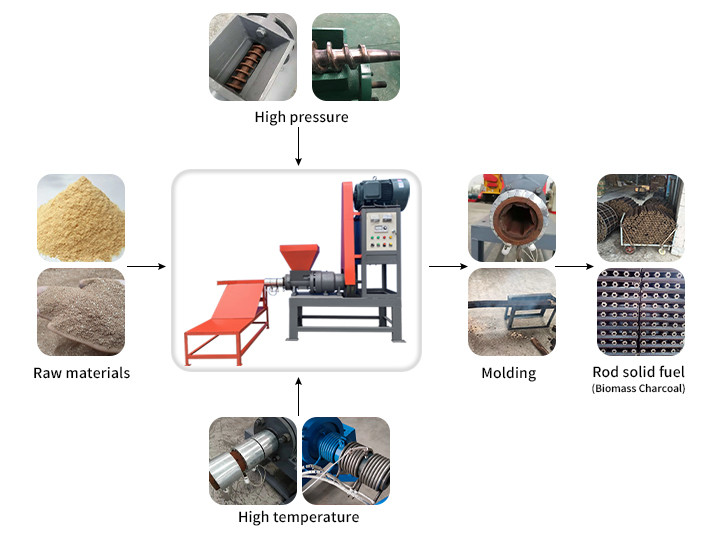

Funktionsprinzip der Holzschnitzelbrikettmaschine

- Vorheizen des Formzylinders: Schalten Sie den Heizring ein, um die Temperatur im Formzylinder auf 280-300 °C zu erhitzen.

- Motor starten: Starten Sie den Motor des Geräts, bereit, das Material zu füttern.

- Zuführen und Extrusionsformen: Die behandelten Rohstoffe in den Zuführungsport geben, und die Schraubenpropeller drücken die Materialien nach vorne.

- Hochtemperatur- und Hochdruckformung: Unter dem Einfluss von hoher Temperatur und Schraubenausdrückdruck wird das Lignin im Material weich und geliert, um dann durch die Form extrudiert zu werden, um hohlstabförmigen Brennstoff herzustellen.

Tipps zur Verwendung der Holzschnitzelbrikettmaschine

Vorbereitung für den Gebrauch

- Überprüfen Sie den Ölstand der Maschine vor dem Start, es wird empfohlen, etwa 750 ml Schmiermittel nachzufüllen.

- Bevor Sie die Maschine starten, lassen Sie sie 10 Minuten lang ohne Last laufen, um sicherzustellen, dass es keine Blockaden oder Verstopfungen gibt. Wenn es irgendwelche Abnormalitäten gibt, stoppen Sie die Maschine sofort zur Untersuchung.

Temperatureinstellung

- Passen Sie die voreingestellte Temperatur entsprechend dem Rohmaterial an: Sägemehl von Mischholz etwa 320 °C, Reishülsen etwa 260 °C.

- Andere Materialien entsprechend der Härte angemessen erhöhen oder verringern, jede Erhöhung der Härte um etwa 10 °C.

Anpassung des Nutzungsprozesses

- Leistung bei zu hoher Temperatur (zu schnelles Herausziehen, schwarze Farbe): Die Temperatur schrittweise um jeweils 3 °C nach unten anpassen, bis der Stabkörper braun ist.

- Die Temperatur ist zu niedrig, Leistung: (die Geschwindigkeit der Leiste ist langsam, die Farbe ist hell): die Temperatur schrittweise nach oben anpassen, jedes Mal um 5 ℃ erhöhen, bis die Leiste normal ist.

Abschaltvorgang

- Bevor Sie die Maschine stoppen, leeren Sie das Restmaterial im Trichter und drücken Sie die Rücktaste, um das Restmaterial von der Propellerwelle zurückzuziehen.

- Nach dem Abschalten der Geräte wird der Heizring weiterhin 10 Minuten lang arbeiten, um die Rückstände im Formzylinder zu karbonisieren, was den nächsten Start erleichtert.

Anzeige der Biomassebrikettiermaschine

Maschinenabgleich Formzylinderanzeige

Die wichtigen Arbeitsbestandteile der Pini Kay Brikettmaschine sind die Schraubenschnecke, der Heizring und der Formzylinder. Aufgrund der hohen Arbeitsintensität nutzen sich diese Teile schnell ab.

Diese Teile, die von Shuliy hergestellt werden, sind von guter Qualität, sehr langlebig und haben eine lange Lebensdauer. Wenn Kunden diese Zubehörteile zurückkaufen, können sie mit einem Rabatt verkauft werden, und sie können kostenlos abgegeben werden, wenn die Kaufmenge groß ist.

Parameter der Biomasse-Sägemehlbrikettmaschine

| Modell | SL-15 | SL-18 | SL-22 |

| Kapazität (kg/h) | 160-200 | 220-260 | 250-300 |

| Motor (kW) | 15 | 18 | 22 |

| Heiztemperatur (℃) | 260-380 | 260-380 | 260-380 |

| Abmessung (mm) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

Verwandtes Video über die Holzschnitzel-Brikettmaschine

Wenn Sie ein starkes Interesse an der Leistung und den Vorteilen der Holz-sägemehlbrikettmaschine entwickelt haben, ermutigen wir Sie, sich umgehend mit unserem professionellen Team in Verbindung zu setzen. Wir sind bereit, Ihnen detaillierte Informationen zu geben, Ihre Fragen zu beantworten und einen Besuch in unserem Werk zu arrangieren, damit Sie die effiziente Produktion und die überlegene Qualität unserer Holzbrikettmaschinen erleben können.