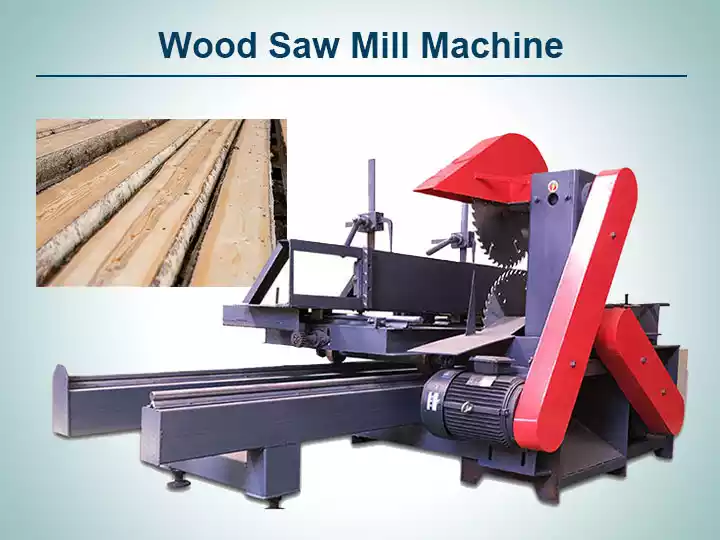

Die Holzsägewerkmaschine kann Holzstämme präzise in dicke Bretter für die Möbelherstellung, den Bau von Gebäuden und die Produktion aller Arten von Holzprodukten sägen. Die Maschine ist mit einem automatischen Zuführsystem und einer intelligenten Geschwindigkeitsregelungsfunktion ausgestattet, die die Sägeblattgeschwindigkeit und den Winkel automatisch an die Härte und Größe des Holzes anpassen kann.

Die Kapazität einer einzelnen Maschine übersteigt 30m³/Stunde und kann täglich 240 Standard-Kiefernstämme verarbeiten. Sie ist geeignet für Sägewerke, Holzschnitzelfabriken, Holzwerkstofffabriken usw. Shuliy bietet drei Arten von Sägewerken an: Rundholz-Sägewerk, vertikales Sägewerk und horizontales Sägewerk, und kann die richtige Ausrüstung entsprechend Ihren unterschiedlichen Bedürfnissen empfehlen.

Einsatzgebiete von Holzsägewerkmaschinen

Die Holzsägewerkmaschinen sind für eine Vielzahl von Szenarien der primären Verarbeitung von Holzstämmen geeignet und werden häufig eingesetzt in:

- Holzbearbeitungsfabriken

- Möbelfabriken

- Baustellen

- Schreinereien

- Holzrecycling- und Wiederverwendungszentrum

Rundholz-Sägewerkmaschine

Die Rundholz-Push-Tischsäge ist eine horizontale automatische Sägemaschine, die das Schneiden durch das Schieben der Rundhölzer realisiert. Sie eignet sich zur Verarbeitung von Rundhölzern oder halb-runden Hölzern mit einem Durchmesser von weniger als oder gleich 50 Zentimetern und ist besonders geeignet für kleine Holzverarbeitungsbetriebe. Mit einfacher Bedienung und präzisem Schneiden ist sie eine wichtige Ausrüstung für die Erstverarbeitung von Rundhölzern zu Brettern.

Strukturelle Zusammensetzung und Arbeitsprinzip

Diese große Holzsägewerkmaschine für Stämme besteht hauptsächlich aus den folgenden Teilen:

- Rahmen und Tisch: unterstützen die gesamte Struktur und tragen die Stämme

- Schubsystem: den Stamm zum Schneiden nach vorne schieben

- Sägewelle und Sägeblatt: um präzises Schneiden bei hoher Geschwindigkeit zu ermöglichen

- Antriebssystem: liefert Schneidkraft

- Leitsystem: sorgt dafür, dass der Stamm reibungslos vorwärts bewegt wird und der Schnitt nicht verschoben wird

- Einstellsystem für die Schnittgröße: flexible Anpassung der Holzstärke

- Sicherheitsvorrichtung: zum Schutz der Sicherheit des Bedieners

Der Arbeitsablauf umfasst: Stamm laden → feste Positionierung → Vorschub des Schiebetisches → Sägen → Größenanpassung → Entladen.

Vorteile der Ausrüstung

- Einstellbare Schnittgröße: der Säabstand kann flexibel je nach Bedarf angepasst werden, um Platten unterschiedlicher Dicke zu schneiden

- Hohe Schneidgenauigkeit: der Schnitt ist glatt und genau in der Größe, was die nachfolgende Verarbeitung erleichtert.

- Verringerung des Holzabfalls: effiziente Nutzung der Stammressourcen und Verbesserung der Materialausnutzung.

- Energieeinsparung und Umweltschutz: Ein Teil der Ausrüstung verwendet energiesparende Technologien, um den Energieverbrauch zu reduzieren und die Anforderungen an den Umweltschutz zu erfüllen.

Technische Parameter

| Modell | SL-300 | SL-400 | SL-500 |

| Maximale Schnittlänge für Holz | 4000mm | 4000mm | 4000mm |

| Max. Durchmesser des zu sägenden Holzes | 3000mm | 4000mm | 5000mm |

| Motorleistung | 7,5KW*2 | 11+7,5kw | 11KW*2 |

| Dimension | 8000X1600X1600mm | ||

| Gewicht | 750KG |

Vertikale Holzsäge Maschine

Das Sägeblatt der vertikalen Holzsägewerkmaschine ist senkrecht zur Arbeitsplatte angeordnet, was das Schneiden von Holz in vertikaler Richtung ermöglicht. Dieses Design eignet sich besonders gut für die Bearbeitung von langen Hölzern oder Platten. Bei der Installation ist es notwendig, ein Loch im Boden zu graben, um die untere Struktur der Sägemaschine zu platzieren, um einen stabilen Betrieb der Ausrüstung zu gewährleisten.

Strukturelle Zusammensetzung

Die Struktur der vertikalen Holzsägewerkmaschine umfasst hauptsächlich das Fundament, den Sägegestell und das Sägeblatt, das Motorsystem, den Arbeitstisch und das Einstellgerät, das Bedienfeld, die Sicherheitsvorrichtung und Hilfsgeräte sowie andere Teile.

Funktionsprinzip

- Stämme fixieren: die Stämme auf dem Arbeitstisch positionieren und fixieren.

- Parameter einstellen: die Schnitttiefe und den Winkel gemäß den Schneidanforderungen einstellen.

- Gerät starten: den Hauptschalter einschalten, das Sägeblatt beginnt sich zu bewegen.

- Schneiden ausführen: der Bediener steuert das Sägeblatt nach unten und vollendet den Holzschnitt.

- Geschwindigkeit anpassen: die Schnittgeschwindigkeit je nach Holzbeschaffenheit anpassen, um einen glatten Schnitt zu gewährleisten.

- Arbeit beenden: den Stamm weiter bewegen für nachfolgende Schnitte, bis alle Bearbeitungen abgeschlossen sind.

Merkmale und Vorteile

- Vertikales Schneiddesign: hohe Schneidgenauigkeit und stabilerer Betrieb.

- Hohe Anpassungsfähigkeit: kann eine Vielzahl von Holzgrößen und -materialien verarbeiten.

- Kompakte Bauweise: geeignet für Holzverarbeitungsstätten mit begrenztem Platz.

- Einfache Bedienung: Das Bedienfeld ist intuitiv und leicht zu starten.

- Gute Geräuschreduzierung: Ausgestattet mit einem vibrationsdämpfenden Gerät zur Reduzierung der Lärmbelastung.

- Geeignet für Batch-Betrieb: Kann mit einem automatischen Zuführgerät verwendet werden, um die Effizienz zu steigern.

Maschinentechnische Daten

| Modell | SL-S3000 | SL-S5000 | |

| Durchmesser des Sägeblatts | 1600mm | 1250mm | |

| Max. Durchmesser des zu sägenden Holzes | 800mm | 1000mm | |

| Motorleistung | 30KW | 45KW | |

| Einstellen der Sägedicke | CNC | ||

| Holzspannmodell | Elektrisch | Hydraulisch | |

| Holzrotation | Hydraulische Walze auf dem Boden | ||

| Maximale Schnittlänge für Holz | 4000mm | 6000mm | |

| Die Länge der Bahn | 10M | 18M | |

| Gewicht | 5000KG | 10000KG |

Horizontale Holzsägewerkmaschine

Die horizontale Holzsägewerkmaschine installiert das Sägeblatt horizontal und ermöglicht das Querschneiden durch das Schieben des Holzes. Sie eignet sich für das effiziente Schneiden von langen Holzstreifen (wie Brettern, Balken, quadratischen Stämmen usw.) und wird häufig in Holzverarbeitungsfabriken, auf Baustellen, in der Möbelherstellung und in anderen Szenarien eingesetzt.

Strukturzusammensetzung und Arbeitsprinzip

Die horizontale Holzsägewerkmaschine besteht hauptsächlich aus den folgenden Teilen:

- Arbeitstisch/Sägetisch: zum reibungslosen Platzieren des Holzes und zum Vorschub.

- Sägehäuser und Sägeblatt: Das Sägeblatt ist horizontal montiert, um Querschnitte zu realisieren.

- Antriebssystem: Um das Sägeblatt anzutreiben und die Schnittkraft bereitzustellen.

- Schnittführungsgerät: Um die Schnittgenauigkeit zu gewährleisten und Versatz zu vermeiden.

- Betriebssystem: Wird verwendet, um Start, Stopp und Schnittgeschwindigkeit zu steuern.

Funktionsprinzip: Befestigen Sie das Holz auf dem Arbeitstisch, starten Sie das Gerät, das Sägeblatt läuft unter dem Antriebssystem, und das Holz wird manuell oder automatisch zum Schneiden geschoben.

Maschinenmerkmale und Vorteile

- Stabiler Schnitt: Das Holz wird horizontal und flach geschnitten, und der Betrieb ist reibungslos.

- Starke Anpassungsfähigkeit: Sie kann eine Vielzahl von Größen und Formen von Holz verarbeiten.

- Einfache Bedienung: einfache Struktur, leicht zu starten, nur eine Person erforderlich.

- Hohe Sicherheit: Der niedrige Schneidetisch verringert das Risiko, dass Holz verrutscht oder spritzt.

- Einfache Wartung: einfache Konstruktion, niedrige Reparatur- und Wartungskosten.

Detaillierte Parameter

| Modell | SL-1500 | SL-2500 |

| Durchmesser des Sägeblatts | 1000mm | 1070mm |

| Max. Durchmesser des zu sägenden Holzes | 1500mm | 2500mm |

| Motorleistung | 37KW | 55KW |

| Einstellen der Sägedicke | 350mm | 450mm |

| Maximale Schnittlänge für Holz | 6000mm | 6000mm |

| Gewicht | 4500kg | 5500kg |

Unsere Fabrik produziert eine komplette Reihe von Holzrecyclinganlagen, wie z. B. Holzhacker, Holzschälmaschinen(Verwandter Beitrag: Holzschälmaschine | Holzstammentrindungsmaschine>>) usw., die je nach Ihren tatsächlichen Bedürfnissen in flexiblen Kombinationen eingesetzt werden können, um Ihnen bei der effizienten Verarbeitung von Stämmen und der Herstellung vielfältiger Holzprodukte zu helfen.

Egal, ob Sie es für die Möbelherstellung, Bauholz oder Holzrecyclingprojekte verwenden, wir können Ihnen professionelle Ausrüstungslösungen und technische Unterstützung bieten. Zögern Sie nicht, uns für weitere Informationen und maßgeschneiderte Dienstleistungen zu kontaktieren!