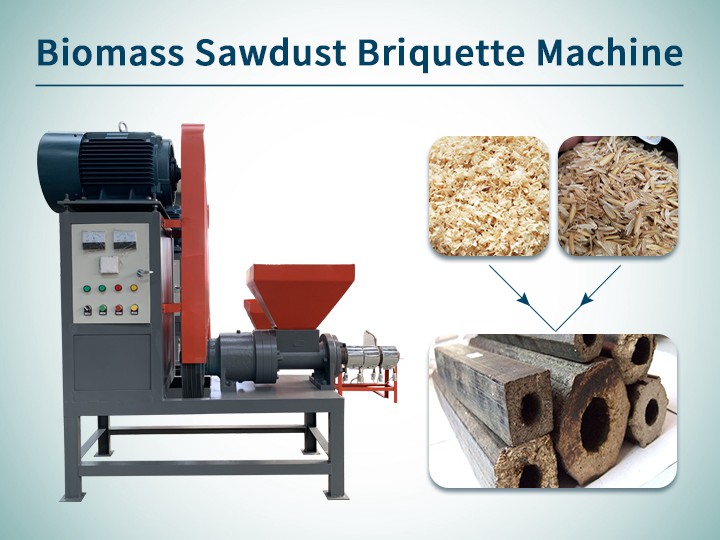

生物质锯末压块机采用高温高压无粘合剂成型技术。它可以将锯末、木屑、稻壳、花生壳、甘蔗渣等农业和林业废弃物压制成密度为1.0-1.4g/cm³的中空棒状生物质燃料。

与普通木材相比,木屑压块更易点燃,热值提高了20%以上,污染更低,密度更高。它易于储存、运输,并能长时间燃烧,为农业和林业废弃物提供了一种经济实用的清洁能源解决方案。

生物质压块的原材料和应用

生物质燃料锯末压块机适用于多种含木质素的农业和林业废弃物,主要包括:

- 木屑、竹屑、刨花

- 稻壳、花生壳、玉米芯

- 棉秆、作物秆、果园和花园修剪的树枝

- 甘蔗渣、椰壳、家具厂、竹制品厂、筷子厂边角料等。

原材料要求:粒度≤5mm;含水量≤12%。(可使用木片粉碎机和滚筒烘干机进行预处理)

木屑压块挤出机成品

锯末压块机制造的生物质燃料棒广泛应用于多个领域:

- 民用取暖燃料:可直接用作家庭壁炉和取暖炉的燃料,尤其在欧洲和美国广泛使用。

- 工业生产原料:适用于家具制造和木制品等工业加工。

- 创意和手工艺:部分木棒可用于手工艺、创意制作及其他特殊领域。

- 农业用途:燃烧后的灰烬可用作磷肥,促进资源的再利用。

- 方便的存储和运输:成品具有高密度、小体积和易于包装(收缩包装),便于存储和运输,降低成本。

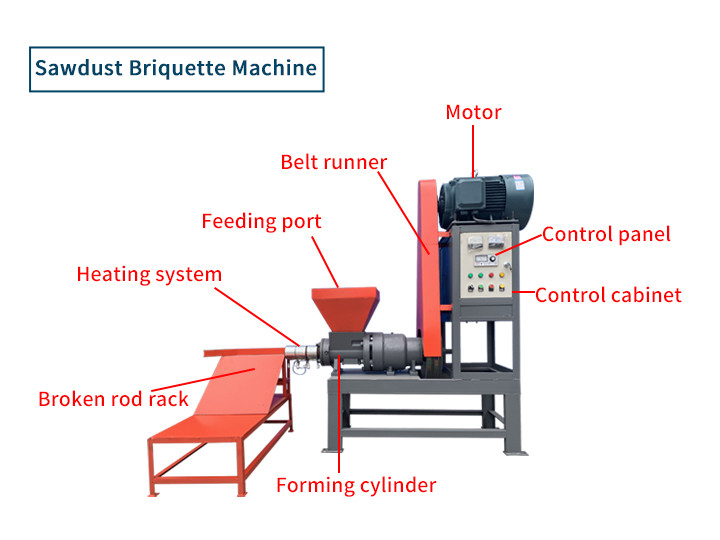

木屑压块机的结构

这款锯末压块机主要由电机、控制柜和控制面板、进料口、成型筒、加热系统等组成。

- 该电机采用高品质全铜核心电机,模具采用铬锰合金,具有良好的耐高温和抗氧化性能。

- 料斗采用大开口设计,方便进料,使进料更加均匀。

- 从出料口有多种型号的模具,也可以根据客户需求定制。

- 出料口配有破杆架,可以控制成型生物炭的长度在10-15厘米之间。

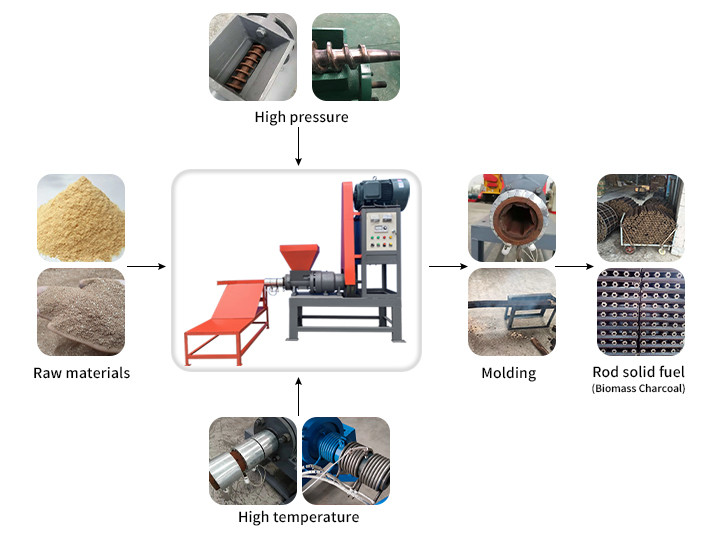

木屑压块机的工作原理

- 预热成型筒:打开加热环,将成型筒内部温度加热至280-300°C。

- 启动电机:启动设备的电机,准备进料。

- 喂料和挤出成型:将处理过的原材料放入进料口,螺旋推进器将材料向前挤出。

- 高温高压成型:在高温和螺杆挤压压力的作用下,材料中的木质素会软化和胶化,然后通过模具挤出,制成中空条状燃料。

木屑压块机使用技巧

使用准备

- 在启动机器之前检查油位,建议加注约750毫升的润滑油。

- 在启动机器之前,先空载运行10分钟,以确保没有卡塞或堵塞。如果发现任何异常,请立即停止机器进行检查。

温度设定

- 根据原材料调整预设温度:混合木屑约320°C,稻壳约260°C。

- 其他材料根据硬度适当增减,每增加约10℃的硬度。

使用过程调整

- 温度过高的表现(太快的突出,黑色):每次将温度逐渐调低3°C,直到棒体变为棕色。

- 温度过低表现:(条形速度慢,颜色浅):逐渐向上调节温度,每次增加5℃,直到条形正常。

停机操作

- 在停止机器之前,请清空料斗中的残余物料,并按下反向按钮以从螺旋桨轴中抽出残余物料。

- 在关闭设备后,加热环将继续工作10分钟,以碳化成型缸中的残留物,这样方便下次启动。

生物质压块机展示

机器匹配成型缸显示

pini kay 制粒机的重要工作部件是螺旋推进器、加热环和成型缸。由于工作强度大,这些部件磨损迅速。

Shuliy生产的这些零件质量很好,耐用性强,使用寿命长。如果客户回购这些配件,可以以折扣价出售,如果购买数量较大,可以免费赠送。

生物质锯末压块机参数

| 型号 | SL-15 | SL-18 | SL-22 |

| 容量 (kg/h) | 160-200 | 220-260 | 250-300 |

| 电机 (kw) | 15 | 18 | 22 |

| 加热温度(℃) | 260-380 | 260-380 | 260-380 |

| 尺寸 (毫米) | 2270X600X1580 | 2390X680X1780 | 2390X680X2150 |

关于木屑压块机的相关视频

如果您对木锯末压块机设备的性能和优势产生了浓厚的兴趣,我们鼓励您立即联系我们的专业团队。我们已准备好为您提供详细信息,解答您的疑问,并安排您参观我们的工厂,亲身体验我们木压块机的高效生产和卓越品质。