蜂窝煤机是由加工过的铁粉木炭/原煤(直径<1mm)制成的,经过混合和压缩形成煤球。成品表面的孔洞使其易于完全燃烧并减少能源浪费。经过多次改进,我们的蜂窝木炭压块机具有结构合理、成品密度高、性能优越和使用寿命长等优点。

另外,您还可以选择其他类型的木炭压块机,包括木炭压块机 | 木炭压块挤压机以及煤球压块机 | 烧烤煤炭压机。

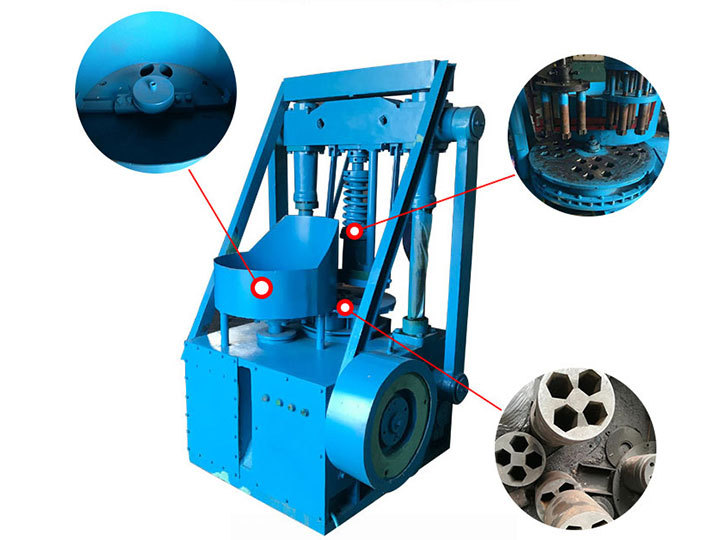

蜂窝煤机的结构与原理

蜂窝煤机结构简单,分为五个部分:机身、旋转、喂料、冲压和输送。这些部分协同工作,操作协调且稳定。

- 机身部分: 由一个平板和一个机器底座组成,这些部分被打开以形成蜂窝煤机的骨架。

- 传动部分: 它由电动机、滑轮、齿轮、传动轴和其他组件组成。电动机通过滑轮旋转齿轮轴,并通过两个齿轮将其传递到传动轴。成对的锥齿轮和旋转轴驱动表盘,表盘转动以移动到四孔盘。

- 进料部分: 它由一个旋转轴、一个料斗和一个搅拌器组成。它由一个轴向齿轮驱动,以搅拌煤粉并将其混合到模具中。

- 冲压部分: 冲压部分主要由四根滑动杆、一个滑动梁、一个冲头杆、一个冲头座、一个冲头、一个可移动压板、一个可移动模具底座和一个弹簧组成。当机器旋转时,两个齿轮通过拉杆旋转以驱动滑动梁。当冲头下降时,冲头被迫向下移动,可移动板向上移动,弹簧被拉紧,煤被压制并冲压,形成的煤松散,由弹簧压制主动板以确定煤的压缩。

- 输送部分: 输送部分由输送框架、滑轮、支架和输送带组成。输送带随机旋转,将成型煤送出机体,输送机上的可调螺丝可以调节输送带的紧度。

煤球机对煤粉的要求

当蜂窝煤机压缩煤粉时,如果煤粉块太大,我们需要先将煤粉破碎,然后再进行压制。同时,通常在使用煤球压制碳粉时,会添加一定量的粘合剂,以达到更好的成型效果。

这是因为当煤粉的水分含量高时,不容易成型。而煤粉和木炭粉必须具有适当的粘结性,否则煤粉和木炭粉必须进行处理。可以将10%到20%的结块煤混入原材料中,以增强其粘结性。

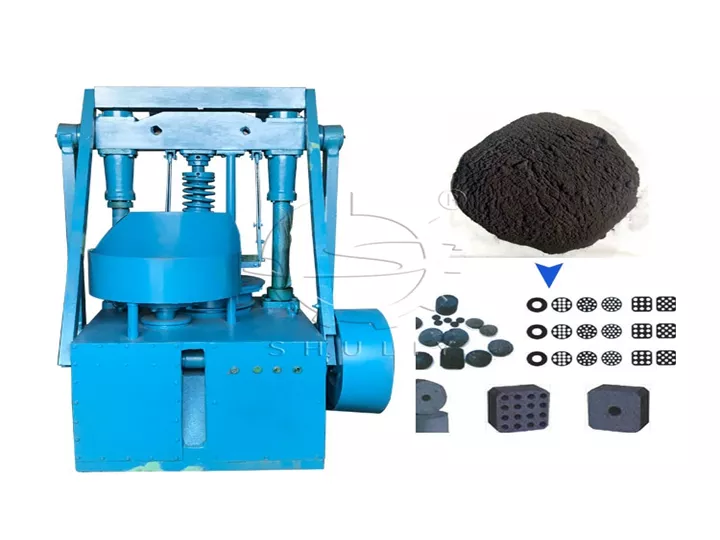

用于制作不同形状木炭球的模具

为了实现一台机器的多功能,我们可以更换压块机的挤出模具,以制造不同形状的压块。通常,蜂窝煤压块是带孔的圆柱形,孔的数量和直径可以定制。

此外,通过更换不同的模具,蜂窝煤机还可以生产带孔的四棱柱和带孔的六角煤球。当然,孔的数量和直径也可以定制。

形状:蜂窝煤粉压块成型机 压块的形状可以是圆形、圆柱形、方形、矩形、多边形、六边形、扇形等多种形状,或者您可以拥有理想的形状,我们可以帮助您满足您的需求。

尺寸:最终尺寸根据形状和机器模具而定,也可以在一定范围内决定。

特点:出口压块具有高密度、易燃、燃烧时间长、无毒、无烟等优点。

煤球成型机的主要特点

- 蜂窝煤机工作效率高,产量大。

- 该机器能耗低,环保。

- 模具完整,易于更换。

- 我们蜂窝煤粉成型机生产的煤球没有化学添加剂或气味,且无烟、无毒、不可燃,因此是一种节能环保的煤炭成型设备。

蜂窝煤压制机参数列表

蜂窝煤机是一种高效且先进技术的生产设备,强大的压力系统和精密设计的模具确保了蜂窝煤的均匀密度和优良质量。其卓越的性能、可靠性、节能和环保为煤炭加工行业带来了可靠和先进的生产解决方案。

| 型号 | 功率 | 容量 | 重量 |

| SL-120 | 4.5千瓦 | 6000件/小时 | 1.4吨 |

| SL-140 | 7.5千瓦 | 8000件/小时 | 1.5吨 |

| SL-160 | 11千瓦 | 10800件/小时 | 2吨 |

| SL-220 | 11千瓦 | 13500个/小时 | 3.8吨 |

煤球成型机工作视频

感谢您对我们先进的蜂窝煤机技术的关注。如果您对我们的产品展示感兴趣并渴望深入了解更多细节,请随时与我们的专业团队联系。我们将为您提供详细的信息,并解答您的疑虑,以确保您做出明智的决定。同时,我们诚挚邀请您参观我们的工厂,以便为您提供直观的体验,让您对我们的技术实力和产品质量有更全面的了解。