La máquina trituradora de madera adopta cuchillas de alta velocidad y tecnología de rotor potente, la velocidad de rotación de la cuchilla puede alcanzar cientos de revoluciones/minuto. A través del corte de alta velocidad de las cuchillas, se logra el impacto y la trituración de troncos, ramas y tablones, y produce astillas de madera, virutas y aserrín uniformes de 3 a 20 mm.

Puede procesar de manera eficiente todo tipo de madera con un diámetro de 1 a 45 cm, y es compatible con bambú, tallos de maíz, tallos de sorgo, mazorcas de maíz y otros desechos agrícolas, reduciendo significativamente el volumen. Se utiliza ampliamente en los campos del reciclaje de madera, fábricas de tableros de partículas y tableros artificiales, fábricas de papel, combustible de biomasa y nueva energía.

La pequeña trituradora de madera tiene una estructura compacta con un nivel de ruido de menos de 75 dB. Es impulsada por un motor eléctrico o un motor diésel para un funcionamiento estable, fácil limpieza y mantenimiento. Soporta el ajuste del espaciado de las cuchillas y la pantalla, y la pantalla o la placa de cuchillas se pueden cambiar según la demanda, para así realizar diferentes tamaños de partículas y estándares de capacidad de manera flexible.

Aspectos destacados de la máquina trituradora de madera

- La capacidad de procesamiento puede alcanzar de 600 a 4000 kg/h, y la capacidad de producción se incrementa en más del 50% en comparación con el modelo tradicional.

- Puede pulverizar varios diámetros de troncos de árboles, ramas y muchos tipos de residuos agrícolas y forestales, con una fuerte compatibilidad de materias primas y un amplio rango de aplicación.

- El 85% del tamaño de partícula descargado es ≤ 3 mm, con una tasa de trituración integral de más del 90%, para garantizar partículas uniformes y estables.

- Al cambiar la combinación de cuchillas, puedes alternar entre astillas de madera (3-20 mm), polvo de madera (≤ 325 mallas) y otras especificaciones de productos terminados.

- Cuerpo compacto, diseño razonable, operación suave y bajo ruido, adecuado para operación continua en todas las condiciones climáticas.

- Toda la máquina solo necesita un motor de accionamiento, alta utilización de energía, la misma producción puede ahorrar alrededor del 40% del costo de electricidad.

- La cubierta trasera del marco superior se puede abrir manualmente y desmontar con una sola tecla, lo que hace que la limpieza y el mantenimiento sean más eficientes.

Aplicaciones de la trituradora de madera y usos del producto terminado

- Las astillas de madera finas se pueden utilizar directamente como pulpa o relleno para la reutilización de residuos de fábricas de papel.

- Las astillas de madera se pueden mezclar con residuos agrícolas para hacer briquetas que se utilizarán como combustible en calderas industriales o para uso doméstico.

- Las fibras de madera se combinan con resinas y se prensan en caliente para producir MDF o HDF, que se utilizan en tapicería, mobiliario y sustratos para suelos.

- Las astillas de madera en descomposición se utilizan como sustrato orgánico para plántulas de flores y cultivo sin suelo de frutas y verduras.

- Las astillas de madera se utilizan como relleno medio para proporcionar un buen soporte y fuente de nutrientes para champiñones comestibles como el shiitake y el enoki.

- Las astillas de madera se rompen a alta temperatura para hacer biochar, que se utiliza para la remediación del suelo (eficiencia de adsorción de metales pesados de hasta el 85%) y el tratamiento de aguas residuales.

- Las briquetas de aserrín se pueden preparar de manera eficiente utilizando astillas de madera finas ≤5 mm, que son la materia prima principal para la máquina de moldeo de briquetas de aserrín.Publicación relacionada: Máquina de briquetas de aserrín | Máquina prensa de briquetas de biomasa>>)

Estructura principal de la máquina de trituración de madera

La máquina trituradora de madera generalmente contiene partes como la entrada de alimentación (se puede personalizar según diferentes materiales), el cuerpo (carcasa), la cámara de pulverización, el disco de cuchillas, la cuchilla, el tamiz (diferentes tamaños de agujeros de tamiz) y la salida de descarga.

La máquina trituradora de madera también se puede equipar con una cinta transportadora según sus requisitos.

Piezas de desgaste clave y mantenimiento

- Juego de herramientas de aleación: vida útil de la cuchilla de 800-1200 horas (3 veces más que la de una herramienta convencional de acero al carbono). La cuchilla del martillo adopta un proceso de cementación y temple, se puede voltear y usar después del desgaste por un solo lado, y la tasa de pérdida se reduce en un 40%.

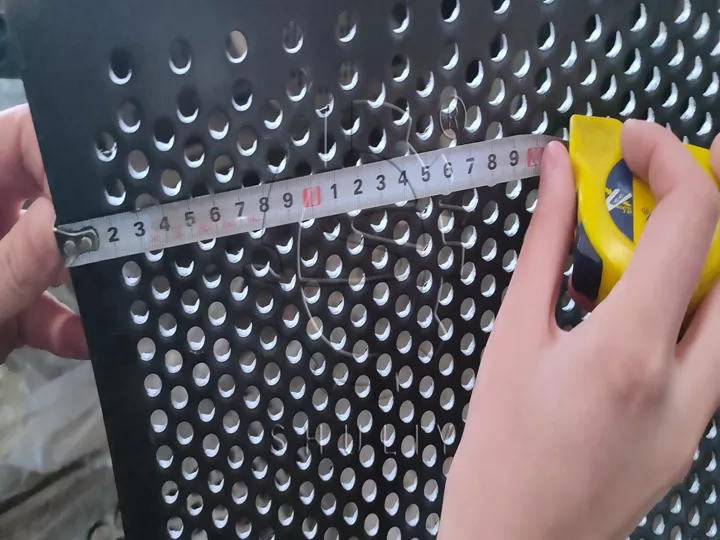

- Pantalla dinámica: placa de pantalla perforada de acero de manganeso alto con resistencia al impacto de 500MPa, soportando más de 5000 impactos de material.

¿Cómo funciona esta máquina de triturar madera?

La madera se envía primero a la sala de trituración de manera uniforme desde el puerto de alimentación, y se corta en astillas de madera y aserrín de 3 a 20 mm rápidamente mediante el corte coordinado y el impacto de la placa cortadora de alta velocidad y las cuchillas.

Posteriormente, las astillas de madera con la finura requerida son tamizadas automáticamente por la criba ajustable y descargadas de manera uniforme a través del puerto de descarga, mientras que los materiales no conformes continúan en el contenedor de trituración para un procesamiento secundario.

Parámetros de la máquina para hacer aserrín de madera

| Modelo | Capacidad | Tamaño de salida | Potencia |

| SL-420 | 600-800KG/H | 0.3-0.8cm | 7.5-11kw |

| SL-500 | 1000-1500KG/H | 0.3-0.8cm | 18.5kw |

| SL-600 | 1500-2000KG/H | 0.3-0.8cm | 30kw |

| SL-700 | 2000-2500KG/H | 0.3-0.8cm | 37kw |

| SL-900 | 2500-3000KG/H | 0.3-0.8cm | 55kw |

| SL-1000 | 3000-4000KG/H | 0.3-0.8cm | 75+7.5kw |

La máquina trituradora de madera es un equipo necesario para el procesamiento y reciclaje de residuos de madera. Puede ser impulsada por un motor eléctrico, un motor diésel o una unidad diésel, y puedes elegir la opción de potencia que mejor se adapte a tus necesidades.

Además, como se muestra en la imagen de arriba, podemos agregar ruedas en la parte inferior de la máquina para que puedas moverte a diferentes escenarios. ¡No dudes en contactarnos para cualquier requerimiento!