The charcoal-making production line is a production line to produce long coal rods, which mainly produces charcoal through the steps of carbonizing raw materials, crushing, forming, and drying. And the appearance of the produced charcoal rods can be customized to realize the diversification of coal production. The charcoal-making production line is currently popular in countries such as Chile, Oman, Vietnam, and Nigeria.

video of the charcoal-making production line

Charcoal-making production line raw materials

The raw materials for producing charcoal are very wide, and can use the resources around, such as some waste wood, coconut shell, rice shell, nut shell, etc. can be used to carbonize and then make charcoal. Therefore, charcoal production is an environmentally friendly project, and it can recycle some waste resources.

Charcoal briquette production equipment molds

The shape of the briquette produced by the charcoal briquette production line can be varied and only the mold of the machine needs to be changed. Generally, the charcoal briquette machine can process hexagonal, square, and round briquettes, etc. And if you want to process special-shaped charcoal, you can customize the mold of the machine.

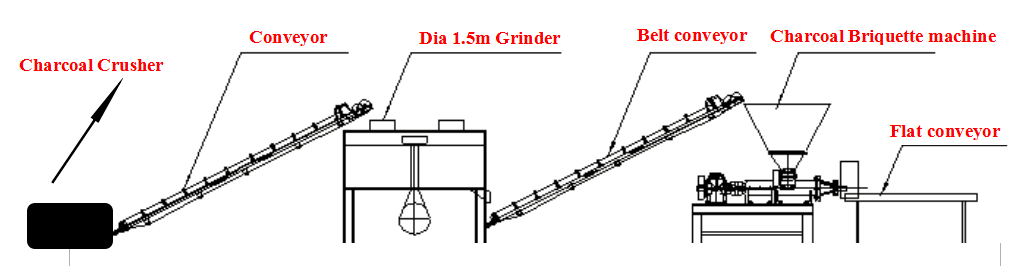

Charcoal making production line production process

carbonization furnace

The raw materials will be put into the carbonization furnace for carbonization. The continuous carbonization furnace can carbonize continuously for 24 hours without interruption, and the production efficiency is very high, the heat generated by its own carbonization can be used in the carbonization process to work in a cycle, and usually, external heating is needed for the first two hours at the beginning of the work, and then it can be self-sufficient by itself.

carbon crusher

The carbon crusher can go through the initial shredding of carbonized materials. This shredder is also often used for wood shredding, crushing branches, miscellaneous wood, and boards into sawdust with the very high efficiency of the hammer blade shredder.

grinding machine

The carbon powder crushed by the grinder is not fine enough and needs to be ground again so that the charcoal produced can burn for a long time. The required particle size of pulverized coal (<3mm).

charcoal mixer

Charcoal forming needs to be mixed with binder and toner so that the hardness of the charcoal produced is sufficient to ensure the hardness of the charcoal.

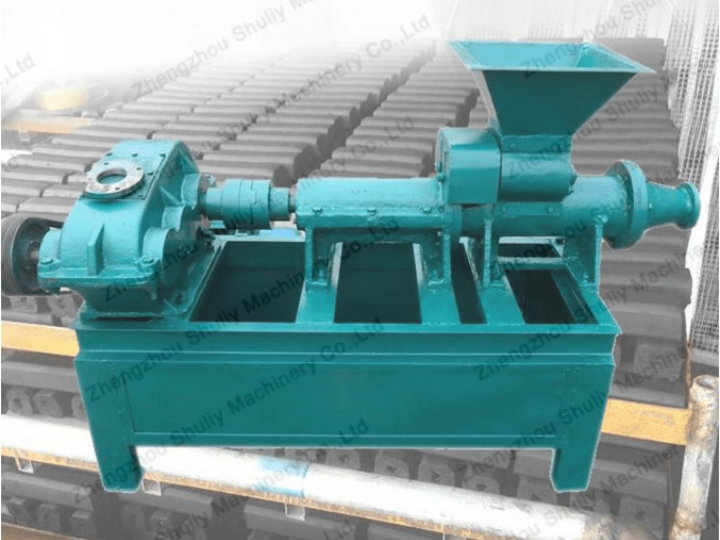

charcoal forming machine

Using the principle of extrusion, the mixed carbon powder is put into the machine, and then the charcoal forming machine will use the power to push out the charcoal from the head of the mold, and the extruded charcoal has high strength and is not fragile.

charcoal dryer

Since the charcoal just produced has a high moisture content, it needs to be dried. This briquette machine line is equipped with a box-type dryer. It can dry charcoal quickly. Of course, you can also choose natural drying, but it may take a longer time.

Parameters of charcoal briquette machine

| Products | Model | Power | Capacity | Weight | Size | Forming specifications(mm) |

| Charcoal forming machine | Type- 140 | 11-4 poles | 0.5T/h | 700kg | 2×0.7×1.2 | 30-40 |

| Charcoal forming machine | Type -180 | 22-4 poles | 1T/h | 1000kg | 2.2×0.8×0.8 | 30-60 |

Charcoal briquette production equipment features

- Fully automated production, high production efficiency

- Charcoal produced has high strength and a long burning time

- Electric box control switch, easy operation, and safer production

- The machine design is compact and compact and occupies a small area

How do ensure the efficiency of the charcoal production line?

- The core of the coal pellet press production line is charcoal forming, so it is important to choose high-quality charcoal forming machine.

- The selection of supporting equipment for the charcoal production line is also very important, the so-called only the best for you, to choose the right mixer, dryer, etc. according to the model of the pellet press, if you choose the model is not suitable will also affect the efficiency.

- In-depth understanding of the material and the performance of the charcoal machine and ancillary equipment, to have skilled operating skills to ensure that the machine automated production.

- For the charcoal production line, reasonable operation and maintenance are necessary to realize its value. Timely maintenance of equipment after production is completed.