Charcoal briquette production line/Charcoal briquette making machine/charcoal production line

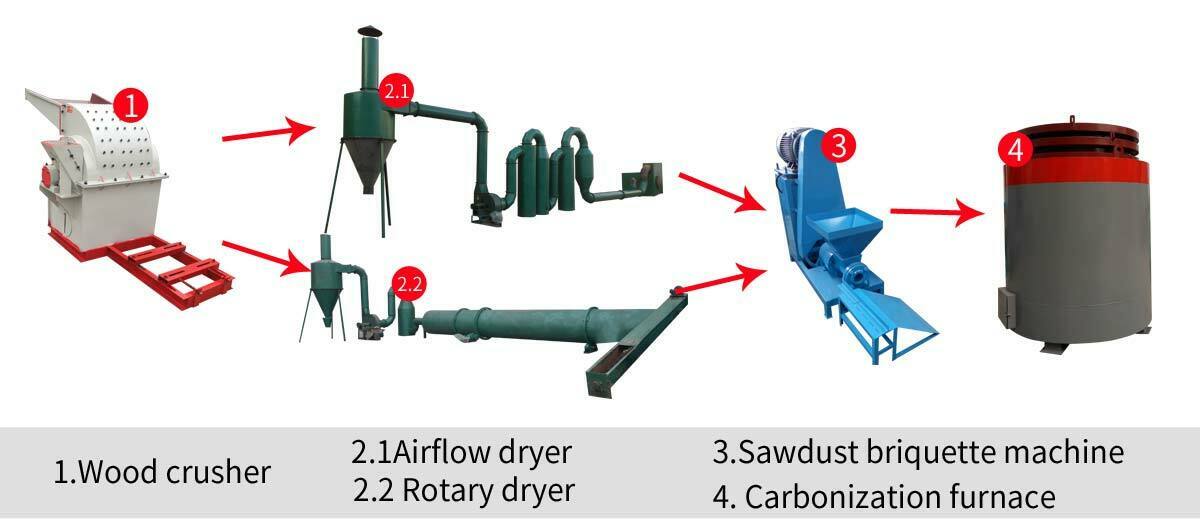

Working flow:

wood crusher-conveyor-dryer machine-conveyor-automatic sawdust feeding machine-charcoal briquette machine-mesh conveyor-carbonization furnace

Description:

Crusher is suitable for crushing raw wood with size less than 200mm (diameter). After milled, the output size can reach diameter 3-5mm, which is suitable for further processing, more suitable for Sawdust charcoal briquette production line.

- Screw conveyor:It is used to transfer the powder to the dryer. You can also use man power instead of this machine.

- Sawdust dryer:If the moisture of the powder is more than 12%. Then you can use this machine. This machine is used to dry the powder to 8%-12% for good working of sawdust charcoal briquette machine.

- Automatic feeding machine and briquette machine:It is used to distributor the powder and make the powder into briquette. The moisture of the powder should be from 8-12% for good working.This machine can make the sawdust charcoal briquette production linemore automatic and high efficiency.

- Mesh belt conveyor:This machine is for the sawdust briquettes,the briquettes is hot after produced from the machine,better use a conveyor for cooling and conveyor.The sawdust briquettes is very hot from the sawdust charcoal briquette machine,this machine can invoid the man to get scald.

- Carbonization furnace:Includes heating room (for heating the stove), furnace body and heat-keeping layer (it is made of the heat insulating material, used for keep the heating)Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel. one set of outer stove include two or three carbonization basket, and the diameter are 1550mm, 1460mm, and 1430mm, and the three carbonization basket can be stack together, easy for loading and transporting ,and it will save a lot of space and transport charge.